by MUNDOLATAS | Aug 29, 2024 | PACKAGING, Technical Papers |

Electrostatic powder coating and interior curing is a process that offers several important advantages and features for the protection of metal containers. Here I explain how this process works and its key aspects: Electrostatic Powder Application Application Process:...

by MUNDOLATAS | Aug 29, 2024 | Control, PACKAGING, Technical Papers |

Objectives of Exterior Varnishing: Provide protection against corrosion. To give a good appearance to the exterior, with decorative and product identification function. Be resistant to sterilization processes. Facilitate and be resistant to mechanization processes....

by MUNDOLATAS | Aug 29, 2024 | Control, PACKAGING, Technical Papers |

To ensure powder adhesion on a container that already has an internal film or coating, several key factors must be considered: Varnish composition: It is essential that the chemical composition and additives of the interior coating are compatible with the...

by MUNDOLATAS | Aug 29, 2024 | PACKAGING, Technical Papers |

To properly maintain the blades of a shear, it is essential to follow a series of steps and recommendations to ensure a clean cut and prolong the life of the blades. Here is a summary of best practices: Cleanliness Regular: The blades should always be clean. Use...

by MUNDOLATAS | Aug 29, 2024 | Canned food, PACKAGING, Technical Papers |

How to improve powder curing and adhesion to the container Lack of powder adhesion to the container can be due to several factors. Some of the possible problems and their corrections are: Burner temperature too low: This can prevent proper melting of the tin, which is...

by MUNDOLATAS | Aug 29, 2024 | CAPS TWIST-OFF, Technical Papers |

information about twist off caps Twist-off lids are metal lids used to close glass or plastic jars, mainly intended for food packaging. These lids can be closed by a quarter-turn or press-on closure, and are opened by twisting or pushing them vertically. They are...

by MUNDOLATAS | Aug 29, 2024 | PACKAGING, Technical Papers |

axial and radial strength tests on tinplate cans Axial and radial strength tests on tinplate cans are important to determine the ability of the cans to withstand the loads and pressures to which they are subjected during use and storage. For axial strength, it is...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

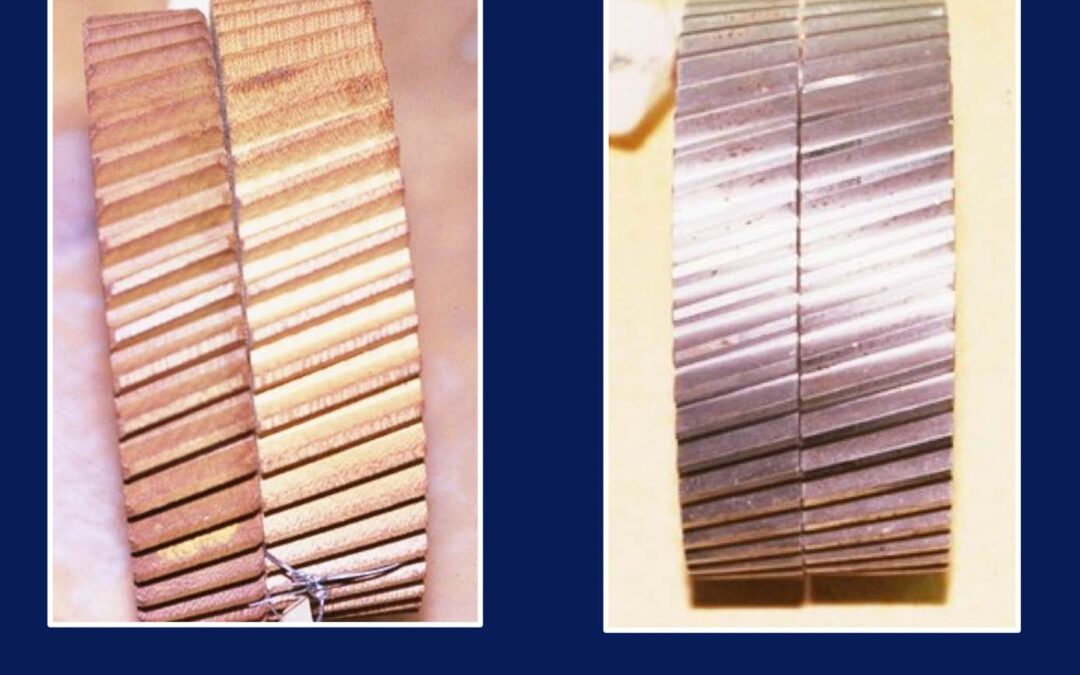

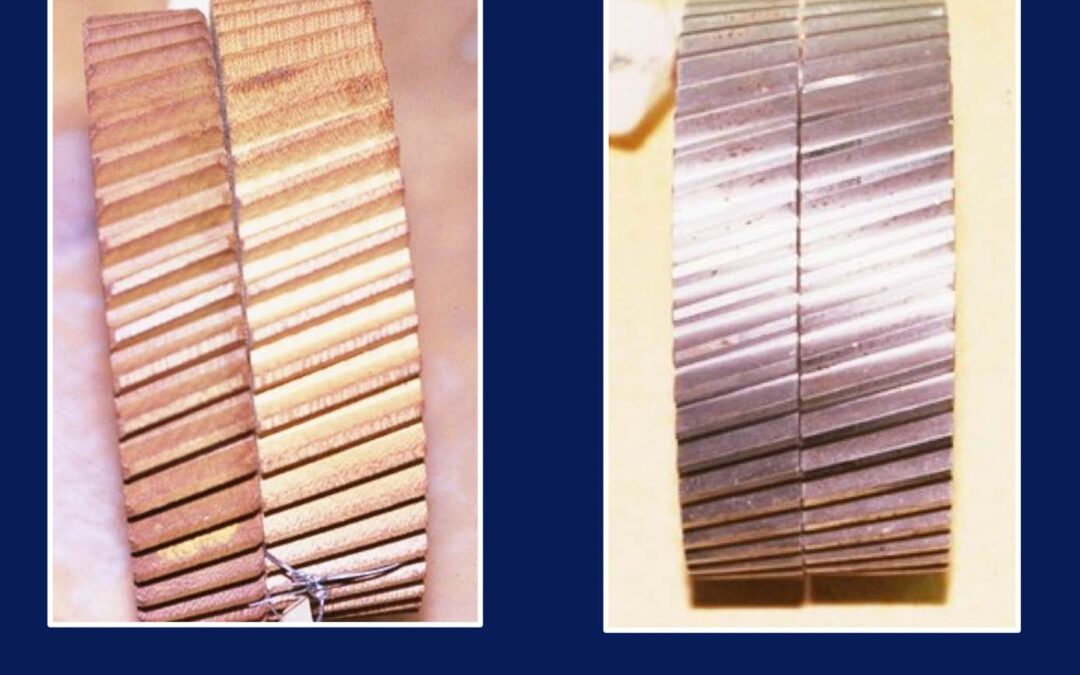

Annealing and Heat Treatment of Metals: Comparison between Bell Annealing (BA) and Continuous Annealing (CA) Annealing is a fundamental heat treatment in the metal packaging industry, whose main objective is to restore ductility to steel after the cold rolling...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Steel Production: The Foundation of Tinplate in the Metal Packaging Industry Tinplate is a widely used material in the metal packaging industry, and its production begins with the manufacture of high quality steel. This steel, which constitutes more than 99% of...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Tinplate Passivation: Surface Protection against Oxidation and Sulfidation Tinplate, a material widely used in the metal packaging industry, requires a surface treatment known as passivation to increase its resistance to oxidation and sulfidation. This process is...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Cold Rolling of Tinplate for Metallic Containers Cold rolling is an essential process in the manufacture of tinplate, which in turn is a critical component in the metal packaging industry. This process involves reducing the thickness of the steel strip through...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Hot Rolling of Tinplate: Technical Process and Considerations Hot rolling is a crucial process in the manufacture of tinplate, a material widely used in the metal packaging industry. This technical process involves several stages and specific considerations to ensure...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Tinplate Electrolytic Tin Plating for the Metal Packaging Industry Tinplate is a key material in the metal packaging industry, and electrolytic tin plating is an essential process in its manufacture. This treatment consists of applying a layer of tin on a low carbon...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Oiling (DOS), a crucial step in canmaking In the metal packaging industry, oiling is an essential process carried out on the surface of cans to ensure proper sliding during manufacture and transport. This procedure not only facilitates can handling, but also plays an...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Pickling on Tinplate: A Key Process in the Metal Packaging Industry Pickling is a fundamental step in the production of tinplate for the metal packaging industry. This process involves cleaning and preparing the surface of the steel to remove the oxide layer that...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Tinplate Tempering in the Manufacture of Metal Containers Tempering is a critical process in the manufacture of tinplate for metal containers, following cold rolling and annealing. This heat treatment adjusts the mechanical properties of the tinplate to obtain the...

by MUNDOLATAS | May 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

Tinplate in the Metal Packaging Industry: Manufacturing Processes and Applications Tinplate is an essential material in the metal packaging industry, valued for its properties such as mechanical strength, formability, tightness and hermeticity. This material consists...

by MUNDOLATAS | Apr 10, 2024 | PRINTING, VARNISHING AND CUTTING, RAW MATERIALS |

Coatings for metal containers include a variety of chemical compounds designed to protect both the contents of the container and the metal against corrosion, deterioration and to maintain the quality of the packaged product. Among the most common types of coatings...

by MUNDOLATAS | Apr 10, 2024 | CAPS & ENDS, Control, Technical Papers |

Physical properties of easy open lids: Easy open closures, also known as easy open closures, have several important physical properties that characterize them: Material: They are commonly manufactured in metal such as tinplate, TFS (Tin Free Steel) or aluminum. The...

by MUNDOLATAS | Apr 10, 2024 | 3PC PACKAGE, PACKAGING, PROCESSES, Technical Papers |

Introduction In the manufacturing process of metal containers, such as three-piece cans, welding plays a crucial role in joining the edges of the sheet metal to form the body of the container. Soudronic, a leading manufacturer of machinery for the packaging industry,...

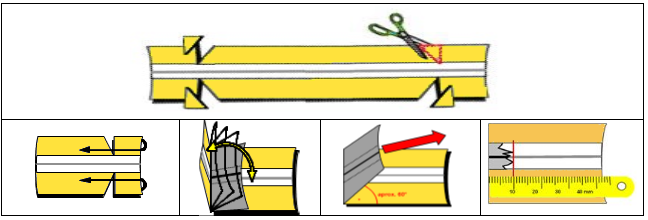

by MUNDOLATAS | Apr 10, 2024 | PRINTING, VARNISHING AND CUTTING, Technical Papers |

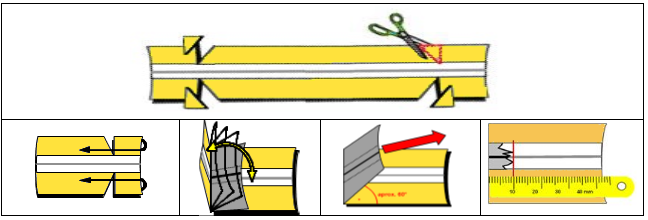

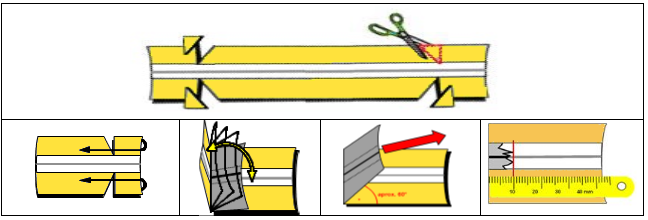

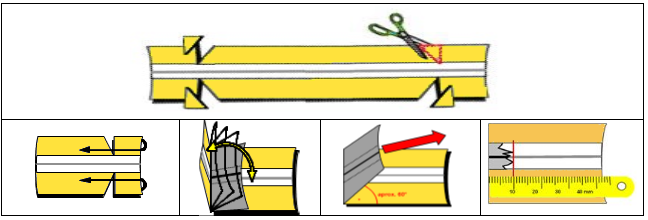

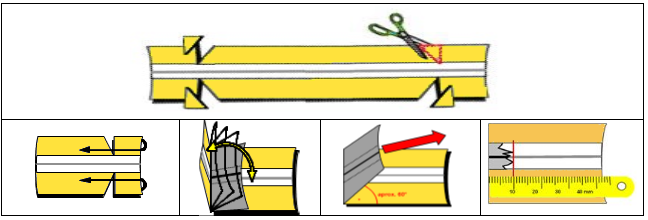

Cutting process in the manufacture of metallic containers The cutting process in the manufacture of tinplate containers and lids is carried out with metal that is received in the form of coils of approximately 10 tons. These coils have different widths, thicknesses,...

by MUNDOLATAS | Apr 10, 2024 | CAPS & ENDS, Frequently Asked Questions, Technical Papers |

How to get a correct rubberizing of a lid In order to achieve a correct rubberizing of a round cap, it is considered necessary that the cap is turned at least two full turns during the application of the rubber, with an overlap of about 5 to 10 mm between the end and...

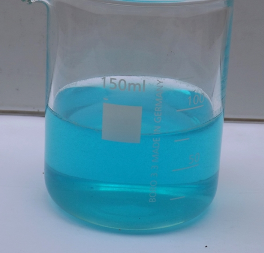

by MUNDOLATAS | Apr 10, 2024 | Canned food, Control, Frequently Asked Questions, PACKAGING, RAW MATERIALS, Technical Papers |

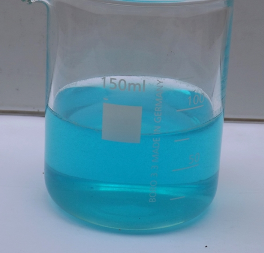

The copper sulfate test is a test used in the packaging industry to detect the presence of pores, cracks, or any discontinuity in the varnish film applied on tinplate cans. This test is important to ensure the quality of the protective coating and to avoid corrosion...

by MUNDOLATAS | Feb 22, 2024 | Canned food, Control, Technical Papers |

The appearance of white spots on the outside of cans may be due to the formation of deposits of dissolved salts, especially if the container is sterilized and removed from the cooling phase at too high a temperature, which generates strong evaporation of the water. In...

by MUNDOLATAS | Jan 31, 2024 | MATERIALS, RAW MATERIALS, Technical Papers |

The basic rules for applying sealing compound to can ends are as follows: The weight of the compound should be monitored regularly to ensure that the correct amount is applied. This is typically done by subtracting the average weight of the ends with the dry compound...

by MUNDOLATAS | Jan 31, 2024 | 3PC PACKAGE, Frequently Asked Questions, PACKAGING, Technical Papers |

To improve the weld on a 610×708 container, several critical factors must be considered based on the information provided: Use of double refrigerated pulley: It is essential to have a welding machine with double refrigerated pulley to obtain a proper weld....

by MUNDOLATAS | Jan 31, 2024 | Control, PACKAGING, Technical Papers |

Leaking cans can be caused by several factors related to the weld and the condition of the can. Some of the possible causes include: Corrosion: There may be corrosion points coming from the outside which, together with secondary corrosion, may generate cracks...

by MUNDOLATAS | Jan 31, 2024 | PACKAGING, RAW MATERIALS, Technical Papers |

Open or cold welds can be caused by several factors that affect weld quality in metal container manufacturing. Based on the information provided, some of the possible causes are: Excessive current: Too high a current can generate excessive heat and affect weld...

by MUNDOLATAS | Jan 31, 2024 | Frequently Asked Questions, PRINTING, VARNISHING AND CUTTING, Technical Papers |

The deficiency of varnish in the inner varnish of the weld can be due to several factors. According to the information provided: Varnish porosity is a problem mentioned, which indicates that the applied varnish may contain micropores that do not provide complete...

by MUNDOLATAS | Jan 31, 2024 | Control, MATERIALS, RAW MATERIALS, Technical Papers |

To identify if the tinplate is of good quality, there are several factors and procedures that can be followed: Visual Inspection: A visual observation should be made both inside and outside of the tinplate containers, complemented with a photographic record to...

by MUNDOLATAS | Jan 31, 2024 | Frequently Asked Questions, MATERIALS, PACKAGING, Technical Papers |

The thickness of tinplate for metal containers is determined by several factors, including the type of container, its end use, and the required mechanical properties. Here are some specific details to consider when determining tinplate thickness: Standard...

by MUNDOLATAS | Jan 31, 2024 | Control, MATERIALS, Technical Papers |

No, TFS is not tinplate. The name TFS comes from the English words “TIN FREE STEEL”, which translates as “tin free steel”. It is also known as “chrome plate”. TFS is a different material that was developed as an alternative to...

by MUNDOLATAS | Jan 11, 2024 | Aluminum cans defects, Control |

The classification of printing defects may vary depending on the standard or criteria used by each company or industry. However, some common categories of can printing defects can be identified: Grease: Presence of any type and amount of grease on the outside of the...

by MUNDOLATAS | Jan 11, 2024 | Frequently Asked Questions, PACKAGING, RAW MATERIALS |

Corrosion of steel in cans is a process in which steel deteriorates due to chemical reaction with its environment, especially in the presence of moisture and oxygen. In the case of food cans, steel corrosion can be a serious problem, as it can lead to food...

by MUNDOLATAS | Jan 11, 2024 | Control, Frequently Asked Questions, PROCESSES, RAW MATERIALS |

The hardness of the tinplate can influence the drawing process in several ways. According to the available information, it is mentioned that the tinplate must have adequate deformation capacity to avoid surface failures during the process. Therefore, it can be...

by MUNDOLATAS | Sep 26, 2023 | DOUBLE SEAM, PACKAGING |

To calculate the correct height between the bottom of the mandrel lip and the bottom plate, you can follow these steps: Start with the height of the flanged can (body only) in millimeters. For example, let’s say it is 116.4 mm. Subtract the thickness of the...

by MUNDOLATAS | Sep 26, 2023 | 3PC PACKAGE, PACKAGING, RAW MATERIALS |

To improve the dosing of electrostatic powder in welding, it is essential to follow some guidelines: Make sure that the particle size of the powder is in the order of a few microns and that it does not contain particles larger than the average thickness of the...

by MUNDOLATAS | Sep 26, 2023 | Canned food, CONTAINERS, PACKAGING |

The can flange plays a key role in the double seam process, ensuring that the seam is formed correctly. During the sewing operation of the first roller, which is considered the most crucial part of forming a good seam, the cover is threaded onto the body flange,...

by MUNDOLATAS | Sep 26, 2023 | Canned food, MATERIALS |

Chloride, specifically sodium chloride (NaCl), can have a corrosive effect on tinplate containers (TFS). Corrosion can be caused by humidity and the presence of chlorides in the environment or in the contents of the container. Corrosion can weaken the packaging...

by MUNDOLATAS | Sep 26, 2023 | DATA, MATERIALS, RAW MATERIALS |

The hardness of tinplate is related to the annealing process and the base steel used in its manufacture. Annealing is a thermal process applied to steel to soften it and improve its ductility. As steel anneals, its hardness decreases and its ability to be drawn and...

by MUNDOLATAS | Sep 26, 2023 | 3PC PACKAGE, MATERIALS, PACKAGING, RAW MATERIALS |

Tinplate can be found in different levels of hardening, which determine its properties and applications. The main levels of tinplate hardening are described below: T1 temper: This is the softest level of tinplate temper. It has high ductility and malleability, making...

by MUNDOLATAS | Sep 26, 2023 | Frequently Asked Questions, MATERIALS |

Tinplate type TH (Tinplate Hard) refers to a tinplate material with a hard temper. However, there is no specific annealing value associated with the term “TH”. The annealing of tinplate may vary depending on the manufacturer and the specific needs of the...

by MUNDOLATAS | Sep 19, 2023 | Frequently Asked Questions, MATERIALS, PRINTING, VARNISHING AND CUTTING, RAW MATERIALS |

To measure the physical properties of a coating, you can perform the following tests: Varnish film thickness: The most accurate method is to weigh a sample of a given surface before and after removal of the varnish film. Normally a circular disk with a surface area of...

by MUNDOLATAS | Sep 19, 2023 | CAPS TWIST-OFF, Frequently Asked Questions |

Twist-off caps are made primarily from tinplate, which is a thin sheet of tin-coated steel. In addition, they use “sealing elements” in the closure made from polyvinyl chloride (PVC) resins to ensure an airtight seal and maintain the freshness and quality...

by MUNDOLATAS | Sep 19, 2023 | Frequently Asked Questions, PRINTING, VARNISHING AND CUTTING, RAW MATERIALS |

Yes, it is possible to apply varnish on a sheet that is already lithographed and has a final varnish. However, it is important to consider a few factors before doing so: Make sure that the additional varnish is compatible with the existing final varnish. There may be...

by MUNDOLATAS | Sep 19, 2023 | Canned food, CAPS & ENDS, Frequently Asked Questions |

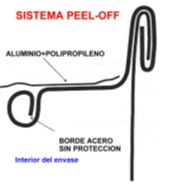

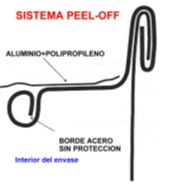

A Peel-Off cap consists of the following main parts: Ring: It is the circular metallic part that fits on the rim of the container. The ring provides the structure and support needed to hold the lid in place and ensure a tight seal. Aluminum foil: A thin, flexible...

by MUNDOLATAS | Sep 19, 2023 | CAPS & ENDS, Frequently Asked Questions |

The foil used in Peel-Off closures is a thin aluminum foil used to hermetically seal the closure ring on metal containers. This aluminum foil is flexible, lightweight and corrosion resistant, making it suitable for maintaining the quality and freshness of packaged...

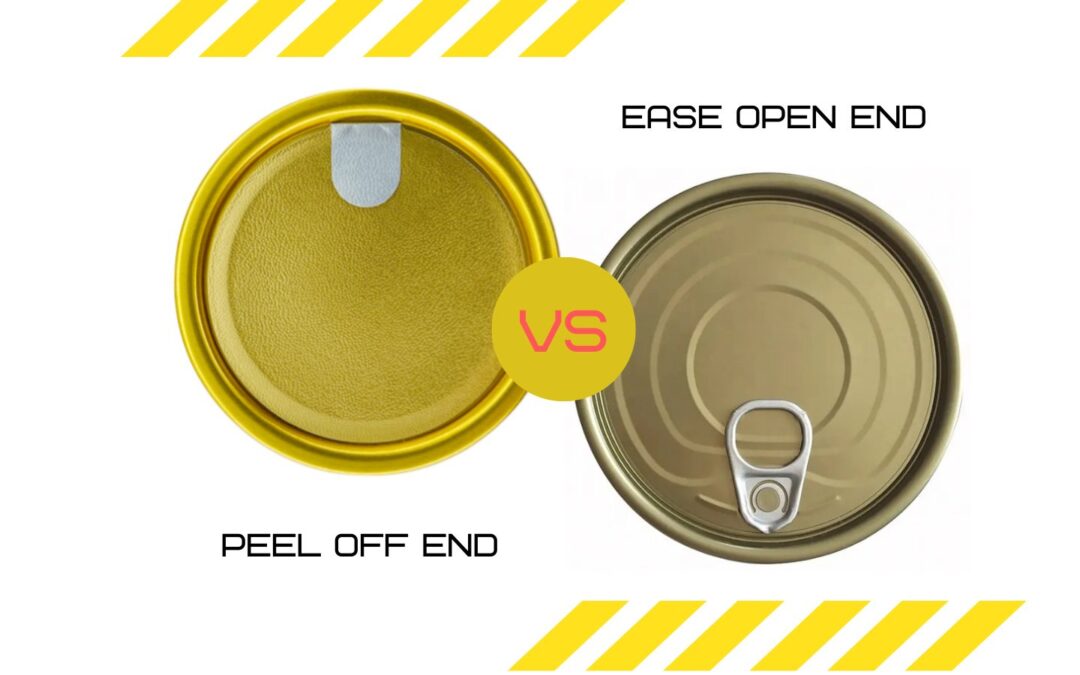

by MUNDOLATAS | Sep 19, 2023 | CAPS & ENDS, Frequently Asked Questions |

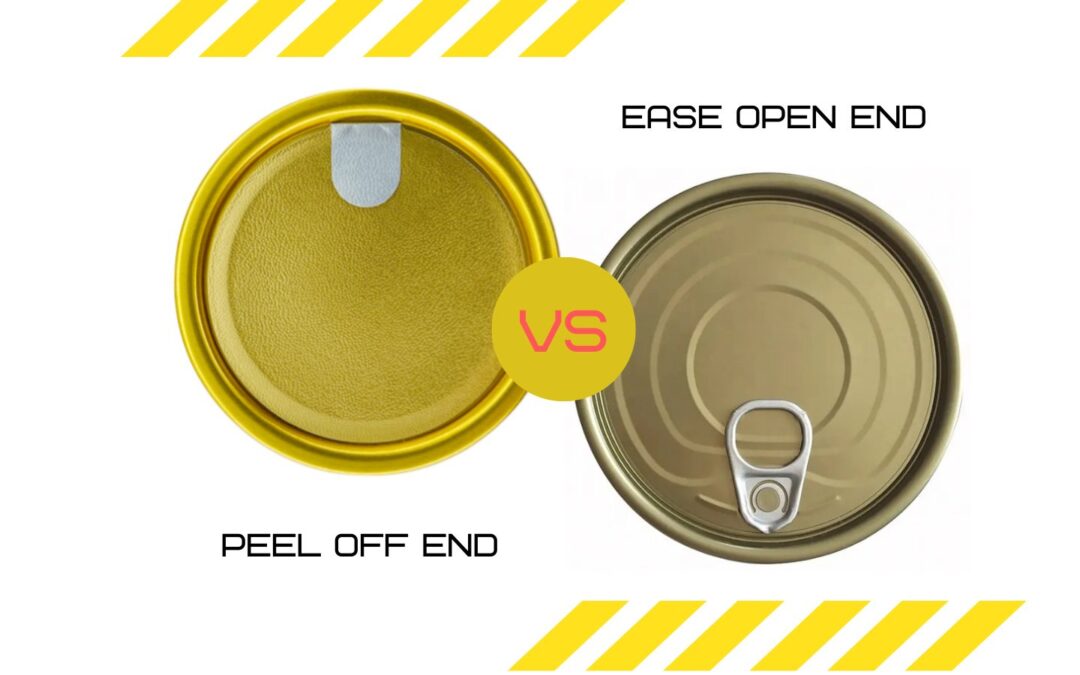

The main difference between Easy Open End (EOE) and Peel-Off Ends lies in their design and opening mechanism: Easy Open End (EOE): These caps are designed with a ring and a precision cut ring on the inside of the cap. When the ring is pulled, the cutting ring detaches...

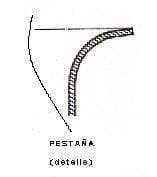

by MUNDOLATAS | Sep 15, 2023 | CONTAINERS, Control, Frequently Asked Questions, PROCESSES, RAW MATERIALS |

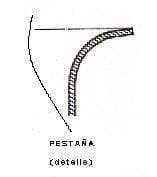

Cracked flanges in the welding of metal containers can be caused by several factors. Some of the most common causes include: Incorrect welding parameters: If the welding current, machine speed or welding roll pressure are not set correctly, it can cause cracked tabs....

by MUNDOLATAS | Sep 11, 2023 | PACKAGING, RAW MATERIALS, Technical Papers |

Hooke’s law applies to elastic materials and describes how a material deforms when an external force is applied. The law states that the deformation (elongation or compression) is proportional to the applied force, up to a certain point called elastic limit. In...

by MUNDOLATAS | Jul 20, 2023 | CONTAINERS, PACKAGING, RAW MATERIALS |

In order to evaluate and approve coatings used in the coating of metal containers, several analyses and tests are carried out. These tests may include: Chemical resistance: The ability of the varnish to resist corrosion and contact with different chemical products...

by MUNDOLATAS | Jul 20, 2023 | Frequently Asked Questions, MATERIALS, RAW MATERIALS |

TFS (Tin Free Steel) is a type of steel coated with a layer of chromium instead of tin. The copper sulfate test is mainly used to evaluate the quality and continuity of the varnish coating on metal cans and containers. In the case of TFS material, if a varnish is...

by MUNDOLATAS | Jun 28, 2023 | 3PC PACKAGE, DATA, PACKAGING, Technical Papers |

In recent years, varnishes applied to tinplate for the manufacture of containers and lids have become increasingly important, as they are applied to most containers, both internally and externally. Together with the continuous changes in European regulations, the...

by MUNDOLATAS | Jun 27, 2023 | CAPS & ENDS, Frequently Asked Questions |

The occurrence of displaced wings in the printing of aerosol bottoms may be due to several factors. Here are some possible causes and solutions: Die wear or damage: Ensure that the die is in good condition and does not have excessive wear. If necessary, replace or...

by MUNDOLATAS | Jun 14, 2023 | Frequently Asked Questions, PRINTING, VARNISHING AND CUTTING, RAW MATERIALS |

Varnishes play a crucial role in the protection and decoration of metal cans. Here are some recommendations for different purposes: Interior varnishes: To protect the contents of the can from corrosion and maintain the quality of the product, it is essential to...

by MUNDOLATAS | Jun 14, 2023 | Frequently Asked Questions, PACKAGING, RAW MATERIALS |

Electrostatic powder coating in can welding is applied to protect the weld zone and prevent metal exposure. Here are some approximate specifications for a “super-wima” type electric welded container: Coating width: Bare container interior: 6 to 7 mm Inside...

by MUNDOLATAS | May 30, 2023 | Control, Frequently Asked Questions, PRINTING, VARNISHING AND CUTTING, RAW MATERIALS |

Introduction Tinplate is a material widely used in the manufacture of metal containers, due to its properties of strength, malleability and protection against corrosion. One of the key aspects in the production of tinplate packaging is the application of varnishes,...

by MUNDOLATAS | May 30, 2023 | Canned food, CAPS & ENDS, CUPS AND ENDS, Technical Papers |

There are several reasons why easy-open lids may come out open after the autoclaving process. Here are some of the possible causes: Excessive pressure during the autoclaving process: If the pressure inside the autoclave is too high, this may cause the lids to open...

by MUNDOLATAS | May 22, 2023 | Frequently Asked Questions, MATERIALS, RAW MATERIALS |

The yield strength of steel is the point at which a material stops behaving elastically and begins to deform plastically. In other words, it is the maximum amount of stress that can be applied to a material without permanent deformation. When a material is subjected...

by MUNDOLATAS | May 22, 2023 | 3PC PACKAGE, Frequently Asked Questions, PACKAGING |

WIMA welding is a resistance welding technique used in the manufacture of metal packaging. This technique was developed by Soudronic in 1975 and is used to weld the side seam of three-piece containers. The WIMA welding technique uses a drawn and flattened copper wire...

by MUNDOLATAS | May 11, 2023 | Canned food, CAPS TWIST-OFF, Frequently Asked Questions |

Introduction Twist-off closures are a popular type of closure used in the packaging industry, especially for food and beverage products. Despite their convenience and ease of use, twist-off caps can have defects that affect their functionality and aesthetics. This...

by MUNDOLATAS | May 10, 2023 | Canned food, Control, DOUBLE SEAM, Frequently Asked Questions, Technical Papers |

To disassemble and analyze the double sealing of a can, you can follow these steps: Cutting and removing the center bottom panel: Use a can opener or similar tool to cut and remove the center panel from the bottom of the can. Cutting two opposite sections of the...

by MUNDOLATAS | May 10, 2023 | Control, Frequently Asked Questions, PACKAGING, RAW MATERIALS, Technical Papers |

Introduction Epoxy varnish is an essential component in the manufacture of food and beverage cans. Its main function is to protect the contents of the package and guarantee the quality of the packaged product. In this technical article, the characteristics,...

by MUNDOLATAS | May 10, 2023 | Control, Frequently Asked Questions, MATERIALS, RAW MATERIALS, Technical Papers |

Introduction BPANI varnish is an innovative coating used in the food and beverage metal packaging industry. This technical article will provide detailed information on BPANI varnish, its properties, applications and benefits in the protection and preservation of...

by MUNDOLATAS | May 10, 2023 | Frequently Asked Questions, News, PRINTING, VARNISHING AND CUTTING, RAW MATERIALS, Technical Papers |

Introduction Varnish is an essential component in the metal packaging industry, providing protection and decoration to containers. Among the different types of varnishes available on the market, BPANI (Bisphenol A Non-Intent) and Epoxy varnishes are two of the most...

by MUNDOLATAS | May 10, 2023 | Frequently Asked Questions, PACKAGING, PROCESSES |

Introduction Welding is an essential process in the manufacture of metal cans, since it allows joining the parts and ensuring the integrity of the container. One of the most common defects in can welding is fishtailing, which can cause problems in the subsequent...

by MUNDOLATAS | May 10, 2023 | Control, Frequently Asked Questions, MATERIALS, News, RAW MATERIALS |

The varnish defect called “eyeballing” is a common problem in the metal packaging industry. This defect is characterized by the appearance of small unvarnished circular areas on the surface of the material, which may affect the quality and appearance of...

by MUNDOLATAS | May 10, 2023 | CAPS TWIST-OFF, CAPS TWIST-OFF, Frequently Asked Questions, News |

Introduction Twist-off closures are a type of metal closure widely used in the packaging industry, especially on glass or plastic jars for food packaging. This article provides a detailed description of the characteristics, manufacturing process and applications of...

by MUNDOLATAS | May 10, 2023 | CAPS & ENDS, CAPS AND ENDS, Frequently Asked Questions, News |

Introduction The crown cap is an essential element in the metal packaging industry, especially in the beverage sector. Also known as chapa in Spain and South America, corcholata in Mexico, platillo in Panama, tapa in Colombia and tillo in Ecuador, this small component...

by MUNDOLATAS | May 10, 2023 | CONTAINERS, Frequently Asked Questions, MATERIALS, News |

Introduction Metal containers are widely used in the food, beverage and consumer products industry due to their durability, strength and shelf life. The printing and decoration of these containers require the use of special inks to ensure proper adhesion and an...

by MUNDOLATAS | May 10, 2023 | 3PC PACKAGE, CONTAINERS, EMBUTITION PACKAGING, Frequently Asked Questions, News, PACKAGING, PRINTING, VARNISHING AND CUTTING |

Introduction Varnishes on metal containers play a fundamental role in the protection and preservation of packaged products. These coatings allow a wide variety of products, from acidic foods to carbonated beverages, to be packaged safely and efficiently. In this...

by Ruben ortiz | Nov 2, 2022 | Control, PACKAGING, Technical Papers |

In short, histamine is an organic compound (amine) resulting from the biochemical reaction of enzymes of certain bacteria on an amino acid called histidine. Histamine ingestion can be dangerous to health when certain limits are exceeded and is therefore...

by Ruben ortiz | Nov 2, 2022 | 2pc Beverage, GENERAL, Technical Papers |

Why Anti-backlash gears are so important and what you can do wrong Anti-backlash gears Anti-Reverse gears are the most important parts of an inking unit, not only is it the inking unit drive with the rubber roller and plate cylinder. It also controls the printing...

by Ruben ortiz | Nov 2, 2022 | CAPS & ENDS, Control, PACKAGING, Technical Papers |

One of the corrosion problems that most concerns the container manufacturer and the canner is the appearance of a type of corrosion that appears on the container and lids in the form of filaments that do not follow a defined shape but usually have a predetermined...

by MUNDOLATAS | Aug 25, 2022 | Control, PACKAGING |

STUDY OF THE LANGELIER INDEX: INFLUENCE OF DIFFERENT PARAMETERS ON WATER AGGRESSIVENESS As we already know, the problems of external corrosion of containers is one of the main problems that appears in the packaging industry, and which causes most of the complaints...

by Mundolatas | Oct 7, 2021 | 3PC PACKAGE, Control, Technical Papers |

As we all know one of the main problems of the packers is the corrosion of the cans. Corrosion of steel is a well-known phenomenon, but in packaging, it is worrying because in the best of cases, it causes a commercial rejection by distributors and consumers. We know...

by Mundolatas | Oct 6, 2021 | 2pc Beverage, Control, PROCESSES, Technical Papers |

In our daily work routine we have to deliver our products together meeting all production indicators. Safety is paramount, product quality, minimal waste, equipment availability and more. All with due importance, taking care to meet the goals and objectives determined...

by MUNDOLATAS | Aug 18, 2021 | Control, PRINTING, VARNISHING AND CUTTING, Technical Papers |

RELATIONSHIP BETWEEN SURFACE ROUGHNESS AND COATING QUALITY Sometimes, a tinplate coated with a well-known varnish that has been applied under perfectly determined conditions shows an abnormally poor physical resistance behaviour. In these cases the blame is often...

by MUNDOLATAS | Mar 23, 2021 | Control, PACKAGING |

Quality control in the manufacture of tinplate containers A canning container must meet certain requirements that make it suitable for the preservation of the canned product. These requirements are based on two fundamental aspects, a physical-chemical resistance that...

by MUNDOLATAS | Dec 29, 2020 | Control |

One of the problems that most concern the canning industry is external corrosion of the containers, since it affects the aesthetics of this, causes commercial rejections and can create sanitary problems when, in extreme cases, the containers are punctured . In order...

by MUNDOLATAS | May 23, 2019 | CAPS TWIST-OFF, Control |

BACKGROUND Nicolás Appert, in Paris and at the end of the 18th century, discovered how to preserve food. In 1795 he started up his first canning workshop. Check that if they are heated, for a certain time foods at 100 ° C, in hermetically sealed containers, these can...

by MUNDOLATAS | May 17, 2019 | Control, PACKAGING |

All the known systems for the determination of the hermeticity in metal containers destined to the canning factories, are based on producing a pressure difference between the inside and the outside of the containers, which is achieved in most of the occasions by the...

by MUNDOLATAS | Apr 2, 2019 | Control, MATERIALS |

Normally the electrolytic tinplate is lubricated with “dioctyl sebacate” (DOS) or with seed oils applied by electrostatic means and whose quantity can be graduated with great precision. The lubricant acts as a protective layer of chromium oxide and...

by MUNDOLATAS | Mar 30, 2019 | CAPS TWIST-OFF, Control |

IIntroduction to the excellent work “INSTRUCTIONS FOR THE CORRECT USE OF THE TWIST, PT, PT PLUS VACUUM COVERS” which, by courtesy of “CROWN CLOSURES EUROPA”, we have the pleasure to publish. Crown Closures Europe INSTRUCTIONS FOR CORRECT USE OF VACUUM COVERS...

by MUNDOLATAS | Mar 30, 2019 | CAPS TWIST-OFF, Control |

It is very important, for the good presentation of a preserves packed in glass jars, closed with “twist-off” type caps that are free of bumps and oxidations. To avoid the presence of the latter, the manufacturer of the covers should take all possible...

by MUNDOLATAS | Mar 30, 2019 | CAPS TWIST-OFF, Control |

SUMMARY In this work, the characteristics of the metal caps used in wide-mouth glass bottles, screw-lock or pressure-sealed, as well as the different types and sizes on the market, the raw materials used in their manufacture, their most common applications and their...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

This article illustrates the quality that should be met by a cap intended for aerosol containers and how to define and control it INTRODUCTION OVERCAPS FOR AEROSOL PACKAGING The objective of this work is the definition of quality characteristics,...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

A canner – canner, filler, etc. – You must define your policy in relation to the quality of your raw materials, among which are metal cans. In relation to these – or to any other product – you can take several positions: a) Full confidence...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

Request a quote Company Directory Online Shop Technical information Mundolatas Consulting News Quality is everyone’s job, including the production team. It is necessary to involve each of the operators of a line in the control tasks. This text gives suggestions...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

The procedure and means necessary to assemble a simple quality control system centered on three-piece cans is described. INTRODUCTION DIMENSIONAL CONTROL OF THREE PIECES TYPE PACKAGING We have already discussed in other works, different aspects of a...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

The cans intended to contain food must have the strength and robustness to allow handling, filling and processing, storage and distribution without damage. The most delicate moment of a container is during the sterilization process to which it is subjected once...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

INTRODUCTION La soldadura eléctrica, de la costura lateral The electrical welding, of the lateral seam of the bodies of the metal containers, is together with the seam of covers and bottoms, the critical point where a boat can present leaks in the manufacturing...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

In the “70s” of the last century, when the new welding technique of the lateral seam of the “three pieces” metal containers began, the “black beast” of the quality of this union was the appearance of “Commas” in...

by MUNDOLATAS | Mar 30, 2019 | Control, PACKAGING |

SUMMARY Determination, in a simple way, of the applied load of powder varnish on the inside face of the side weld, of a can once finished. INTRODUCTION The electric welding, which joins the side seam of three-piece cans, is a sensitive area that must be...

by MUNDOLATAS | Mar 30, 2019 | CAPS & ENDS, Control |

SUMMARY Mode and means to control the quality of the curl of the domes for aerosol containers on which the valve is mounted. PREAMBLE The aerosols are equipped with a metering valve for the product, which is attached to the top of the metal lid or...

by MUNDOLATAS | Mar 30, 2019 | CAPS & ENDS, Control |

SUMMARY In this article, we will try to describe an inexpensive way to verify the internal pressure, which supports the cap of a container intended to contain paint, before being expelled. BACKGROUND The present work is applicable to the different types...

by MUNDOLATAS | Mar 30, 2019 | CAPS & ENDS, Control |

The means and the way to perform a dimensional control of ends, applying simple and reliable procedures, are treated in this technical article. INTRODUCTION In the metal industry, the purchase or exchange of already manufactured components is common (ends,...

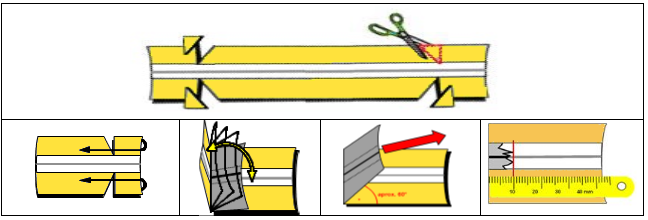

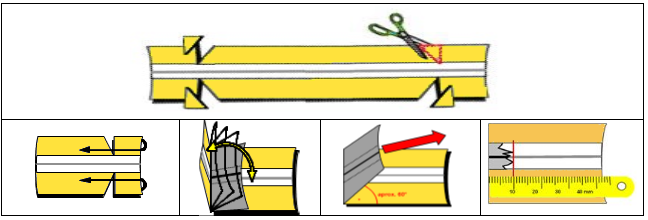

by MUNDOLATAS | Mar 30, 2019 | Control, PRINTING, VARNISHING AND CUTTING |

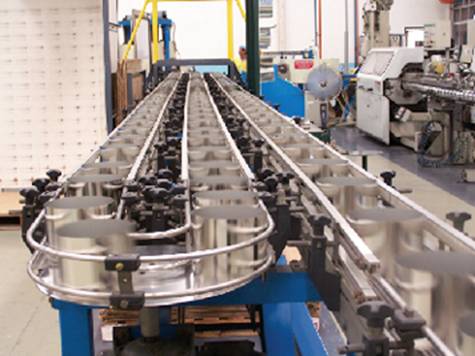

SUMMARY Description and location of quality control points on a coil cutting line INTRODUCTION The lines of cut of coils are installations, that little by little have been doing habitual in the plants of manufacture of containers. Initially, there was a high...

by MUNDOLATAS | Mar 30, 2019 | Control, PRINTING, VARNISHING AND CUTTING |

SUMMARY Determination and evaluation of the porosity of the interior varnish of a can by means of a high hardness test. It describes how to control the different parts of the boat. PRESENTATION Porosity means the smallest points inside a can protected...

by MUNDOLATAS | Mar 30, 2019 | Control, PRINTING, VARNISHING AND CUTTING |

The protection both external and internal of a metal container by means of varnishes is a very normal technique that already has a history of more than 150 years. In other technical articles of this Web the varnishes are analyzed from different points of view:...