- Objectives of Exterior Varnishing:

- Provide protection against corrosion.

- To give a good appearance to the exterior, with decorative and product identification function.

- Be resistant to sterilization processes.

- Facilitate and be resistant to mechanization processes.

- Abrasion resistant.

- Types of Varnishes:

- Vinyl, Acrylic or Epoxy-Phenolic: These exterior coatings are applied to protect tinplate from external corrosion. They can be colorless or, in some cases, gold-plated.

- Finishing Varnish: It is a transparent varnish applied over the printing to protect it, since the inks have little resistance to abrasion.

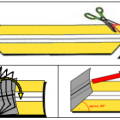

- Application Process:

- Varnishing table: The required weight of varnish is applied and the varnished sheets are placed on grills that guide them through an oven to cure the varnish.

- Curing Oven: The sheets pass through an oven where the varnish is cured, ensuring that the applied coating is durable and resistant.

- Exterior coating:

- To protect the outer weld and preserve the integrity of the can, a protective varnish is applied to the side seam. This varnish is usually colorless and fast drying.

- Quality Control:

- Tests are carried out to control the quality of varnish application, ensuring that the protection and appearance objectives are met.

Control | PACKAGING | Technical Papers

Información Técnicaexterior coating

0 Comments