Introduction

In the manufacturing process of metal containers, such as three-piece cans, welding plays a crucial role in joining the edges of the sheet metal to form the body of the container. Soudronic, a leading manufacturer of machinery for the packaging industry, has developed DISCON welding rollers, an essential component for resistance welding.

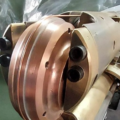

Description of DISCON Welding Rollers

DISCON welding rollers are specialized rollers used on Soudronic resistance welding machines with special cooling system. These wheels are responsible for applying the pressure and heat necessary to form a continuous, high quality weld on the can bodies.

Technical Characteristics

- High initial friction: DISCON sheaves are characterized by considerable friction at the beginning (sliding contact), which decreases after a short period of operation.

- Maintenance: It is recommended to grind the profile of the welding rollers at least once a week to maintain the efficiency of the welding process.

- Emulsion temperature: It is crucial to check the return temperature of the DSE emulsion, which must not exceed 45 °C.

Maintenance and Use

Proper maintenance of DISCON welding rollers is vital to ensure weld quality. This includes:

- Annual cleaning of the emulsion system: The DISCON Stabillo DSE emulsion system should be cleaned and the emulsion changed annually, regardless of the hours of operation.

- Profile check: It is necessary to check and rectify the profile of the sheaves regularly to avoid defects in the weld.

DISCON Stabillo DSE Emulsion

DISCON Stabillo DSE emulsion is a combination of coolant and lubricant used in the DISCON cooling circuit of Soudronic welding machines. It is supplied as a concentrate to be diluted with water and must be stored under controlled conditions to maintain its effectiveness.

Problems and Solutions

- Overheating: If the thermal circuit breaker of the secondary circuit reacts by overheating, the profile and surface of the inner welding roller should be checked.

- Dirt: The inner sheave is exposed to dirt and must be cleaned after each shift to avoid welding problems.

Conclusion

DISCON welding rollers are a critical component on Soudronic welding machines, and their proper maintenance ensures the integrity and quality of welds in the production of metal packaging. Attention to initial friction, profile maintenance and emulsion temperature management are key aspects for the optimal performance of these sheaves.

0 Comments