As we all know one of the main problems of the packers is the corrosion of the cans.

Corrosion of steel is a well-known phenomenon, but in packaging, it is worrying because in the best of cases, it causes a commercial rejection by distributors and consumers.

We know that it is practically impossible for a steel container with external varnish, which should be protected from external aggressions, to keep the varnish film intact after the handling and processing of the containers, due to the fact that they suffer friction and knocks between them during the different manufacturing and processing operations.

If the containers are properly treated, no external corrosion should appear in spite of these unavoidable external aggressions, but in many cases, corrosions appear and we need to know how to avoid them in the different points where they can appear.

The most common is that they occur in finished product warehouses, and the control of the environmental humidity of these warehouses is one of the main factors to control in order to avoid corrosion.

Ambient air always contains water vapour. Under the influence of climatic elements, and their variation, this water vapor causes various phenomena such as:

- Electrochemical corrosion, rust, corrosion inhibitors

- Hydrolysis of certain products.

- Electrical accidents (short-circuits, bad contacts, etc.)

Inside packaging and warehouses, condensation is essentially due to temperature drops, which cause a depression of the internal atmosphere, favouring the entry of humid air from outside.

The causes of temperature rises and falls are diverse, and may be caused by: Day-night or seasonal variations. Climatic variations (e.g. during transport) or variations due to the proximity of intermittent heat-generating equipment (e.g. engines that start and stop, air-conditioning units, etc.) or humidity (humid vapour inputs from production plants, etc.),

Experience has shown that harmful phenomena occur when the relative humidity indoors exceeds 30% humidity at 18°C temperature. It is therefore essential to keep the humidity under control or at least put the necessary means in place to avoid the formation of phenomena such as those mentioned above.

To fix the humidity, a dehydrating agent capable of absorbing and retaining it is used. The dehydrating agent must not be harmful or deteriorate the material or product it is intended to protect. For practical use, the dehydrator is packaged in permeable paper or tissue sachets.

HYGROMETRIC DEGREE. –

The hygrometric degree, or relative humidity, of the air is defined by the ratio between the amount of water vapour in the air at a given temperature and the maximum amount that saturates the air at the same temperature. It is usually expressed as a percentage.

E.g.: At 25º C, saturated air (100% relative humidity) contains 23 g of water per m3. At the same temperature and a relative humidity of 50%, one m3 of air contains only 11.5 g (logically, half).

It is called dew point, the temperature ‘Tr’ at which the air has to be cooled to see the first drop of condensed water appear.

The relative humidity of the air at temperature ‘Tr’ or dew point is 100%.

For example, air containing 23 grams of water per m3 at 38ºC can be cooled to 25ºC, at which temperature it will be saturated and the first signs of condensation will appear.

The higher the water vapour content or the greater the temperature drop, the greater the risk of condensation.

Example: At a temperature of 35ºC, 1 m3 of air contains:

- 7.88 g water vapour at 20 % RH

- 19,8 g water vapour at 50 % RH

- 29.5 g water vapour at 75 % RH

With these amounts of water vapour, condensation will form if the temperature drops to:

- 7ºC for a water vapour weight of 7.88 g (drop of 28ºC)

- 23ºC for a water vapour weight of 19.8 g (drop of 12ºC)

- 30ºC for a water vapour weight of 20.5 g (drop of 5ºC)

DEHYDRATING AGENTS.

Dehydrating agents are products which, when used under certain conditions, absorb the excess water vapour trapped inside the packaging.

Dehydrators must meet the following standards:

- NF H 00320 French Standard

- MIL D 3464 American Standard

- DIN 55473 German Standard

DEHYDRATING UNIT.

The French dehydrating unit (DU) is the quantity of dehydrating agent capable of absorbing, at a temperature of 20 ± 3ºC, any of the following humidities:

- 100 g of water vapour at a relative humidity of 40 %.

- 80 g of water vapour at a relative humidity of 30 %.

- 60 g of water vapour at a relative humidity of 20 %.

The French dehydrating unit (1 DU) is slightly higher than 16 American units (MIL D 3464) and 16 German units (DIN 55733).

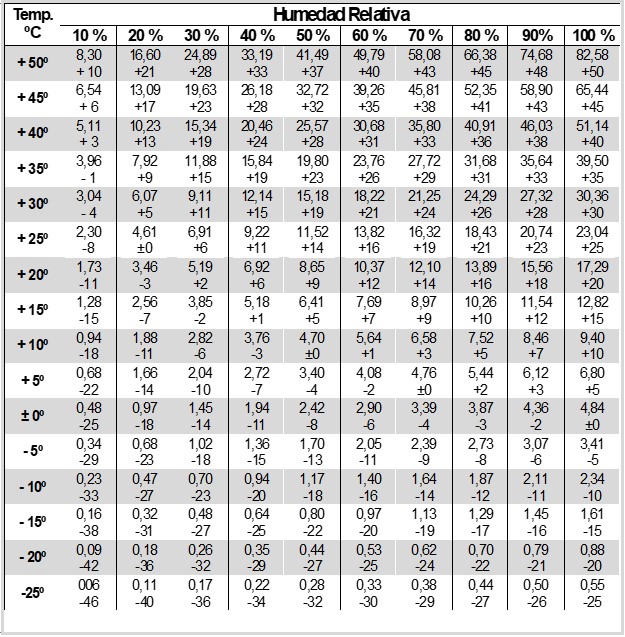

CLIMATE TABLE

In this table I, the ambient dry temperature is specified in the left column. At the top, the % relative humidity is displayed in 10% steps.

For each temperature and % RH, the quantity of water contained in the air at these conditions is indicated in the corresponding table in gr of water/m3 , in gr of water/m3 .3 of air (at the top) and the temperature at which that air becomes saturated, thus reaching the dew point and water condensation. So, for example, for a dry temperature of 25ºC and a RH of 50%, the air contains 11.52 grams of water/m³ and the temperature at which this water would condense would be 14ºC, i.e. if the temperature drops 11 degrees, condensation could start. On the other hand, if the RH were 80%, the air would contain 18.43 grams of water per m³, and this water would condense at 21ºC, that is to say, only a drop in temperature of 4ºC would imply the onset of condensation.Knowing this, it is necessary that in the cellars and in the packaging of the containers, the temperature and humidity are controlled, in order to know the conditions that are available, and thus put means to avoid condensation on the containers and corrosion problems, which cause rejections in the market, and therefore considerable economic losses.

Nowadays, there is equipment that measures the temperature and humidity continuously or every certain time interval, and many of them provide software that indicates the risk of moisture condensation (or dew point) so it is relatively easy to control this type of problem in warehouses.

DATALOGGER

Nowadays, there is continuous RH and temperature measurement equipment, with a computer dump, which, for less than 100 euros, stores this information for several months depending on the measurement frequency that is set, and which, in many cases, even have software that allows the data to be analysed and the risk of condensation due to dew point to be evaluated.

José Fco. Pérez Gómez

Mundolatas Advisor

0 Comments