The basic rules for applying sealing compound to can ends are as follows:

- The weight of the compound should be monitored regularly to ensure that the correct amount is applied. This is typically done by subtracting the average weight of the ends with the dry compound applied from their weight prior to compound application.

- The uniformity of the compound should be monitored to ensure that there are no holes or gaps at the ends that have received compound. This helps prevent seam bulges and ensures a complete seal.

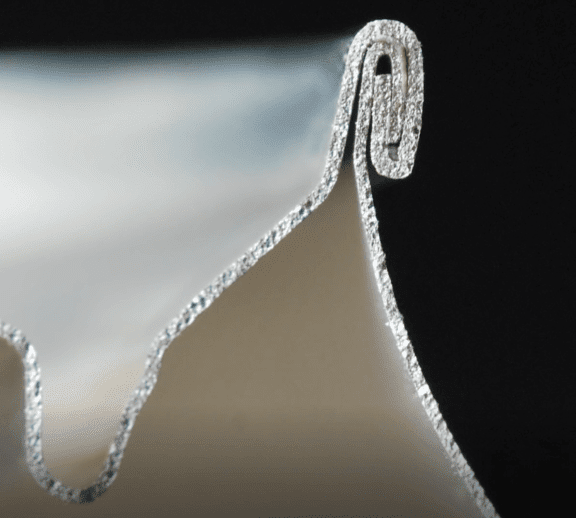

- An optimum volume of sealing compound should be applied to the end of the can to fill the voids naturally present in the metal-to-metal joint that is the double seam. This is critical to create an airtight seal.

- For non-round ends, variations in film weight can be considered acceptable within the range of -5% to +15%, while for round ends, variations can be kept within ±10%.

- The primary means of controlling film weights with machines operating on the flat die principle is by controlling the width of the die face.

- Correct dry film weight using the right product, proper peripheral distribution and proper radial distribution are important to avoid increasing the risk of seam or seal defects.

- Proper matching of compound and application conditions is key, aiming for a continuous film free of visual defects.

- Excessive amounts of compound may cause distortion of the double seam structure and may cause “extrusion” or leakage of compound from the double seam.

- Increasing the amount of sealing compound will not compensate for loose, defective or poorly formed seams.

- The proper amount and correct placement of the compound on the end of the can during the application process is critical.

- The sealing compound should be applied evenly around the circumference of the end at the specified film weight, as uneven distribution can result in uneven film thickness and faster aging of thinner films.

- The final coating or varnish over which the composite is applied is also critical, as composites age at different rates when applied over different coatings.

These rules are essential to ensure that the sealing compound performs its function effectively, providing a secure and leak-proof double seam.

0 Comments