Double seaming is a fundamental process in the manufacture of metal containers, such as food and beverage cans. This process ensures that the contents of the package are well sealed and protected from external factors such as humidity and air, thus maintaining the quality and freshness of the product inside.

The double closure consists of two main stages:

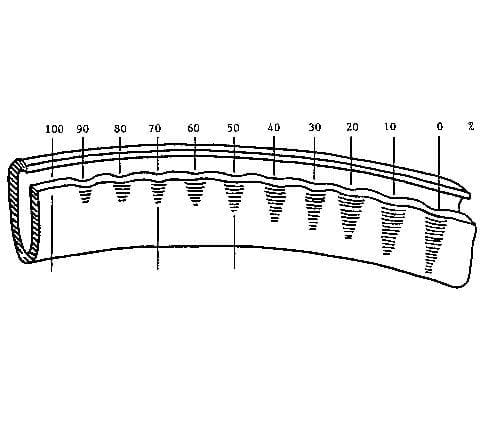

- First operation: At this stage, a hook is created between the can body and the lid. The lid is placed on the can body, and a seaming machine wraps the rim of the lid around the rim of the body, forming an initial hook.

- Second operation: In this stage, the hooks formed in the first operation are compressed and sealed together. The closing machine uses closing rollers to press and seal the hooks, thus creating an airtight closure that protects the contents of the container.

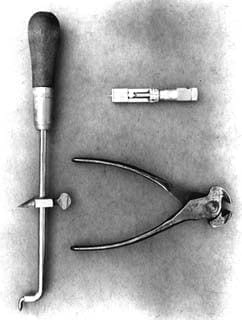

Quality control is essential in the double sealing process, as a defective closure can compromise the integrity of the package and, consequently, the quality of the product inside. Therefore, it is important to carry out regular inspections and use appropriate tools to ensure a tight and high quality seal.