SUMMARY

Essential measures to take into account in an aerosol cone, for its assembly in the package.

INTRODUCTION

To ensure interchangeability between the different parts, which make up a tinplate aerosol container of the 3-piece type, it is necessary to standardize and standardize a series of measurements on the dome of said container and on the double closing between it and its notched cylindrical body. Three different elements complement each other in this area of the package:

-1º.- The metallic container itself.

– 2nd.- The diffuser valve

– 3rd.- The cap

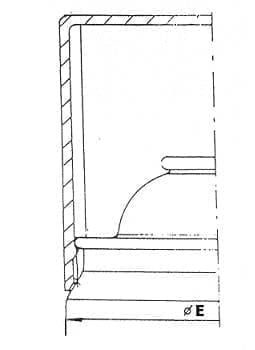

The valve is mounted on the central hole of the dome, while the nails of the cap fix it to the double closing between the dome-body of the container. In drawing no. 1 the latter is appreciated.

Figure 1: Fastening the cap to the container

Therefore, the design of these elements must be linked together to ensure the correct assembly of them. Normally, the manufacture of these components is carried out by different producers, so a prior standardization is necessary to facilitate the coordination between them.

DEFINITION OF BASIC MEASURES

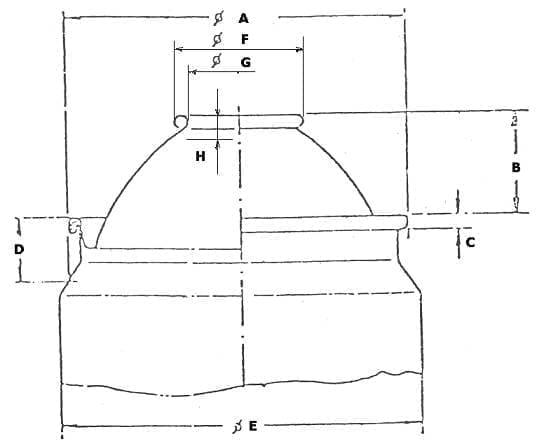

There are eight main averages in the dome, closure and body that form the group of dimensions to be standardized. In figure 1 the same are marked on a detail of this part of the metal container.

Figure nº 1: Upper part of a notched container

The importance of them is determined by:

A.- Outside diameter of the closure. The fastening system of the cap on the container is attached to it.

B.- Distance from the top of the valve seat curl to the top of the closure. The B level is critical for the pushbutton-cap manufacturers and directly affects the heights of the same.

C.- Height of the closing. Determine the position of the hook of the cap.

D.- Distance from the top of the closure, to the point of the notching of the body, located in the same vertical as the outer diameter of the closure. Mark the point of contact between cap and body of the container, and therefore delimit the height from the nail to the edge of the cap.

E.- External diameter of the container body. Define the outer diameter of the cap.

F.- Outside diameter of the curl of the dome.

G- Inside diameter of the curl of the dome.

H.- Contact height in the curl of the dome.

These last three measures (F, G and H) link the dome with the valve, allowing a correct clinching of the second on the container, Likewise F and G define the radius of the curl, since it is equal to a quarter of the difference between both.

VALUES

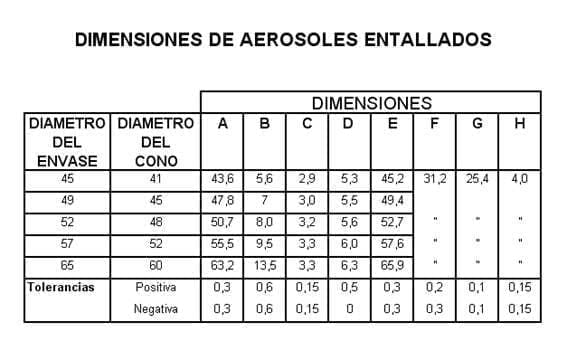

In the following chart the values that take these measures for the different diameters of notched containers are indicated.

Comments:

– These values of the measurements are suitable for containers designed for a pressure test of 12 bars. In the case of aerosols capable of withstanding a pressure test of 15-18 bars, the values will be affected by the greater thickness of the sheet.

– The diameter “A” must not be measured in the area of the body seam.

– The three measurements F, G and H are kept constant for all aerosol diameters.

– To measure the contact height “H”, a special standard gauge must be used and its value must be taken at three equidistant points around the cone. The variation of this mean within the same dome must be between 0 and 0.20 mm.

0 Comments