SUMMARY

The paint and varnish industry consumes large quantities of metal containers. These containers have the particularity of being airtight, but with an easy access to be used as containers, at the moment of the application of its content. This leads to different solutions. This paper reviews those based on a frictional seal. It details the single, double and triple friction seals, their basic criteria, characteristics and peculiarities.

INTRODUCTION

Metal containers have long been used for the transport, handling and use of varnishes, paints, lacquers and other industrial products. These have a number of special characteristics, which differentiate them from those used in food. The main reason is that they are not subjected to sterilization and heat treatment. For this reason it is usually sufficient for the bottoms to be flat and the bodies smooth. On the other hand, the lids have a very special design.

The aim of all this is to meet a series of conditions that cover the following requirements:

– Properly preserve the contents, i.e. maintain a good seal.

– Function as a bucket at the time of use. Therefore, it must be possible to wet the brush or roller in them, so they must have as large a mouth as possible.

– Keep the leftover product well stored, that is to be able to hermetically close this mouth by means of a cap once partially used.

All of the above is achieved by replacing the top lid on the container with two elements:

– A ring, which is a lid with a large central hole.

– A plug that snaps onto the rim.

This fitting pressure is achieved by making the diameter of the plug slightly larger than the diameter of the ring bore. This generates a frictional force or friction between the side walls of the ring and plug, thus ensuring that the assembly remains reasonably firm.

Over time, different ways of making this fit between the ring and the cap have been developed, giving rise to various types of closures for paint containers and similar. We will describe below the most important among them, the way they work, their materials and measurement ratios. There are other types of closures such as those used in pails, buckets, etc. but they will not be discussed in this paper.

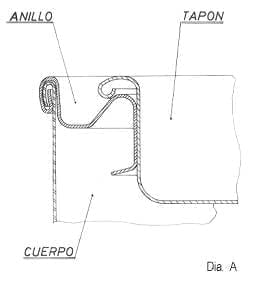

SIMPLE FRICTION

This is the most common closing in this market. Its design is quite classic and its use began more than a century ago. As can be seen in figure nº 1, the plug adapts to the ring along a single vertical wall, producing the closure by the force generated in the elastic and reciprocal deformation of both elements.

Figure 1: Simple friction seal

It is a closure that combines the advantages of simplicity and economy in tinplate, both in thickness and hardness. On the contrary, it has a number of drawbacks that make it outdated today. The main ones are:

– Steel seen in the edge of the skirt of the ring, which causes when used in water based paints, very frequent nowadays, that a light oxide film is formed in the upper part of the content, originated when the iron reacts with the water.

– Cutting hairs on the brushes, when they are impregnated with paint as the edge of the ring is usually quite sharp. These hairs are deposited on the paintwork and contaminate it.

– Its unique sealing surface does not show a solid firmness to the tightness and is therefore not very reliable.

– The rings are not stackable and therefore give rise to certain difficulties when feeding them into an automatic seamer.

– The caps are not stackable either and complicate the automatic closing process at the filler’s premises.

Despite these limitations, it performs well enough to remain in the market, with a significant market share.

Some characteristics of this type of closure are:

– Tinplate normally used:

Hoops: 0.26 to 0.27 temper T3. E 2.8

Plugs: 0.25 to 0.26 tempera T3 E2.8

Depending on the diameter of the container. They are therefore quite normal.

– The diameter of the mouth

A

The diameter of the mouth, see figure 1, is approximately 10 to 12 mm smaller than the diameter of the container.

– The net height of the sealing wall is 4 to 6 mm at the rim and 9 to 12 mm at the plug.

All these references of measures, and those that we will be indicating for other types of closures, are always indicated for container diameters up to 110 mm. In superiors its value increases.

For the correct design of the tooling, it is necessary to know that the measurements of the parts that form the closing wall do not coincide exactly with the final measurements of the ring and cap, which is very important, as it can lead to a defective closing later on. It is therefore necessary to take into account the elastic recovery – deformation – of the tinplate in the finished components, in order to compensate it with the measurements of the tooling parts.

The following table shows for three groups of different container diameters, the formulas that approximately define the measures of the diameter of the mouth of the container, in the dies of the rim and cap, to obtain a value of

A

These formulas have been determined by practice and for normal conditions of use, and using a tinplate and ring and stopper stockings similar to those indicated above.

|

SIMPLE FRICTION |

||||||

|

Values of the friction diameter A |

||||||

|

Hoop |

Plug |

|||||

|

Container diameter |

< 73 |

73 a 99 |

> 99 |

< 73 |

73 a 99 |

> 99 |

|

Value of A in the part |

A |

A |

A |

A + 0,22 |

A + 0,30 |

A + 0,50 |

|

Value of A in the tooling |

A + 0,07 |

A + 0,10 |

A + 0,15 |

A + 0,17 |

A + 0,25 |

A + 0,40 |

So, for example, for a container diameter of 83 mm, if we want the ring to have a mouth opening A, for the friction seal to work properly, the stopper should have a diameter of A + 0.30. For this purpose the part of the ring tooling that determines the diameter A should have a value of A + 0.10 mm and that of the plug tooling A + 0.25.

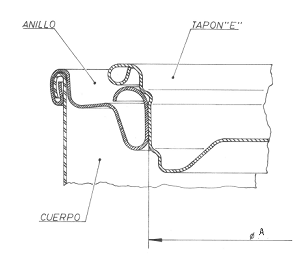

IMPROVED SIMPLE FRICTION

In Central Europe, especially in France, a more elaborate version of the simple friction lock was developed to overcome the problems presented by the simple friction lock. Figure 2 shows its characteristics.

Figure 2: Improved single friction seal

It is still a simple friction lock, because it has only one locking surface, but it has the following advantages over the classic lock:

– The cutting edge of the ring mouth is positioned outside the closure and therefore away from the contact of the paint, so there is no danger of oxidation.

– This cutting edge will not cut hairs on the brushes either, as it is curved inwards and therefore protected.

– The shapes of the ring and cap allow better control of their configuration, obtaining greater precision in their measurements. The “V” design of the ring wall allows it a certain elasticity, which generates a greater pressure on the wall of the plug. The reinforcements on the wall of the cap make it more rigid. All this generates a more uniform and secure seal.

– Due to its design, it is possible to lower at least 0.01 mm the thickness of the tinplate used in both elements.

– The hoops are better handled in the feeder of the seamer as they are not fully stackable, but they are more stackable than in the first case.

– In the stoppers, the step at the base and the lateral bead at the top allow an acceptable stackability. In the stack of plugs, the upper plug penetrates the lower plug in the area of its recess and rests on the bead of the lower plug.

All this makes this solution significantly better than the first version of a simple friction lock.

On the other hand, its manufacture requires several operations, three for the ring and two for the cap, which makes installation and tooling more expensive.

Some characteristics of this type of closure are:

– Tinplate normally used:

Rings and plugs: 0.24 to 0.25 temper T3. E 2.8. Depending on the diameter of the container. They are therefore quite normal.

– The diameter of the mouth

A

The diameter of the mouth, see figure 1, is approximately 12 to 14 mm smaller than the diameter of the container.

– The net height of the sealing wall is 5 to 6 mm at the rim and 9 to 11 mm at the plug.

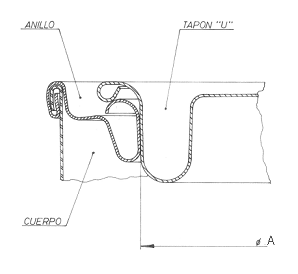

There is another variant of this closure, in which, using the same type of rings, the plugs have a different shape, a “U” type plug, see figure nº 3.

Figure 3: Improved single friction seal with “U” type plug

It has the advantage that this type of closures are fully stackable, which greatly facilitates the operation of capping the container at the filler’s house, as the speed of the operation can be greatly increased.

As with the classic simple friction seal, the recovery of the metal foil must be taken into account. Therefore, the dimensions of the tooling must also be rectified in relation to the finished elements. Following an analogous criterion to the first case, in the following table we show the values of these adjustments for different diameters.

|

IMPROVED SIMPLE FRICTION |

||||||

|

Values of the friction diameter A |

|

|

|

|

||

|

|

||||||

|

Hoop |

Plug |

|||||

|

Container diameter |

< 73 |

73 a 99 |

> 99 |

< 73 |

73 a 99 |

> 99 |

|

Value of A in the part |

A |

A |

A |

A + 0,35 |

A + 0,45 |

A + 055 |

|

Value of A in the tooling |

A + 0,10 |

A + 0,15 |

A + 0,20 |

A + 0,30 |

A + 0,40 |

A + 0,50 |

In this matter, also the formulas are experimental and for material values and parts similar to the one indicated. These data should therefore only be taken as an indication, a practical verification is always necessary in each specific case.

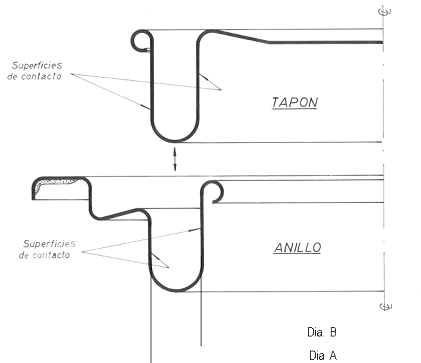

DOUBLE FRICTION

Another significant advance in the improvement of the friction seal was the introduction of the double seal. This actually came after the triple closure, which we will see below, and is actually a simplification of the latter. It arose as a way of circumventing the patents covering the triple lock, and its practical results are very close to it.

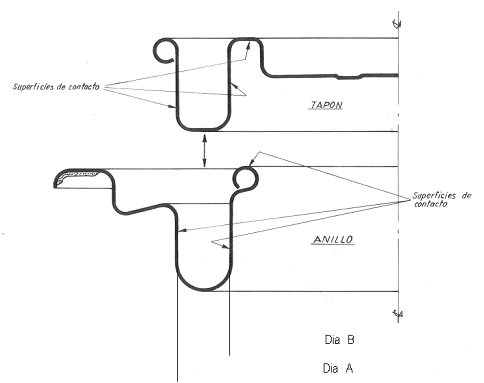

In this development, the main contribution is to double the sealing surfaces, thus achieving a double sealing barrier. Figure 5 shows a drawing of such a seal and indicates the areas that rub against each other.

Figure 5: Double friction seal

The improvements are as follows:

– As we have already said, hermeticity is more complete, due to the action of the double wall friction seal.

– Good stackability of hoops, although it is necessary to modify the feeder of the seamer to make it effective, due to the great height of the hoops.

– Excellent stackability of the caps.

On the contrary, it has certain disadvantages, such as:

– Necessity to use more expensive tin plate

– Cutting edge at the mouth of the ring on the inside, and therefore at risk of oxidation.

Some characteristics of this type of closure are:

– Tinplate normally used:

Rings: 0.25 T1 for small diameters and 0.26 T2 from 99 mm and up.

Plugs: 0.25 T2 for small diameters to 0.26 T2 tempering for the rest.

Tinning always E 2.8.

Therefore they are slightly more expensive than the previous cases.

– The diameter of the mouth, see figure 1, is approximately 18 to 26 mm smaller than the diameter of the container. Diameter B is 7 to 8 mm smaller than diameter A.

– The total height of the plug is between 7 to 9, depending on the diameter.

The following table gives the empirical formulas to be used for the calculation of the A and B diameters of the parts and tooling. The same considerations as above apply, but now extended to two diameters instead of one.

|

DOUBLE FRICTION |

|||||||

|

Values of the friction diameter A and B |

|

|

|

|

|||

|

|

|

||||||

|

Hoop |

Plug |

||||||

|

Container diameter |

< 73 |

73 a 99 |

> 99 |

< 73 |

73 a 99 |

> 99 |

|

|

Piece |

Diameter A |

A |

A |

A |

A + 0,04 |

A + 0,06 |

A + 0,08 |

|

Diameter B |

B |

B |

B |

B + 0,13 |

B + 0,15 |

B + 0,23 |

|

|

Tooling |

Diameter A |

A + 0,02 |

A + 0,03 |

A + 0,04 |

A + 0,10 |

A + 0,13 |

A + 0,16 |

|

Diameter B |

B+ 0,10 |

B + 0,10 |

B + 0,15 |

B – 0,05 |

B – 0,10 |

B – 0,10 |

|

Both the ring and the plug require to be manufactured in two operations.

TRIPLE FRICTION

This improvement, as we have already said, is previous to the double friction, it was put on the market in North America in the middle of the last century. A diagram of the same is shown in figure nº 6.

Figure no. 6: Triple friction seal

The following improvements are available:

– A third sealing zone between the top of the ring crimp and the inner channel of the plug.

– Outer position of the hoop curl.

– Stackability of rings and plugs.

The tinplate can be the same as the one used for the double closure, as well as the criteria for the size of the container mouth and the height of the cap.

The formulas are also very similar to the case of double locking, and are shown in the following table:

|

TRIPLE FRICTION |

|||||||

|

Values of the friction diameter A and B |

|

|

|

|

|||

|

|

|

||||||

|

Hoop |

Plug |

||||||

|

Container diameter |

< 73 |

73 a 99 |

> 99 |

< 73 |

73 a 99 |

> 99 |

|

|

Piece |

Diameter A |

A |

A |

A |

A + 0,04 |

A + 0,06 |

A + 0,08 |

|

Diameter B |

B |

B |

B |

B + 0,13 |

B + 0,15 |

B + 0,23 |

|

|

Tooling |

Diameter A |

A + 0,02 |

A + 0,03 |

A + 0,04 |

A + 0,10 |

A + 0,13 |

A + 0,16 |

|

Diameter B |

B+ 0,10 |

B + 0,10 |

B + 0,15 |

B – 0,05 |

B – 0,05 |

B – 0,05 |

|

The rim requires three operations for its formation and two for the plug. The design of each of them will be the subject of another work.

These four solutions presented allow each manufacturer to choose the option most in line with their commercial approach. Obviously, the increase in the quality of the fastener is linked to a higher investment in tooling and an increase in its direct cost.

0 Comments