Analysis of the evolution of the height of the body of an aerosol container during the different stages of its manufacture.

INTRODUCTION

Throughout the manufacturing process, the initial height of the flat body of the container, is reduced slightly in each stage, until reaching its final value once the finished container.

It is very important to know the decrease of this height in each step, for several reasons:

– The important dimension to obtain is that of the finished packaging, since it is what marks its capacity. Therefore, starting from it it is necessary to know how much to increase it, to define the height of the cut of the flat body.

– For the process to be under control, it is necessary to adjust each step of the process properly. Hence, it is necessary to know in each of them the data that vary from one to another. As we have indicated, the height is reduced in each phase and its theoretical value must be known and controlled.

The decreases in height in each stage are greatly influenced by several factors:

– By the standards used in each operation, and therefore the design of the tools used in them. For example, the shape that is given to the notching of both ends of the body, influences the loss of height of the same.

– For the technique used in the process. For example, it is not the same to make a notch by tampon to stationary container, than by rulina to rotating container.

– For the number of operations that comprise the entire process, then to reach an equal result, you can use different options in the number of steps to follow. For example, the notching can be done first, followed by the flanging of the body, or both operations simultaneously.

– For the characteristics of the machines used in manufacturing. For example, the same results are not achieved with combined machines – transfer type – with multiple horizontal heads, than with independent vertical machines.

VALUES

From the previous comments, it can be seen that it is not possible to accurately determine, a priori, the height variations that are produced in the different steps in the manufacture of an aerosol container. It is best to determine in each case the height losses generated in a first theoretical manner, and then practically.

At the orientation level and taking into account that the influence of the above mentioned factors are always small, we can give a concrete example of the evolution of these heights.

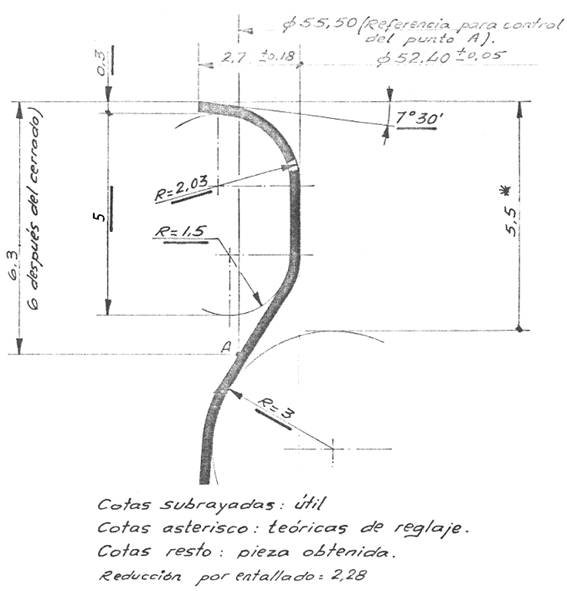

We will start with a notched and flanged design as indicated in drawing no. 1. It is quite usual in aerosol containers, with a body diameter of 57 mm, bottom 54 and dome 52.

Figure nº 1: Flanged aerosol dome side diameter 57

The other end of the body will have a notch similar to the one shown, but with a smaller diameter reduction to adjust it to the bottom of diameter 54 mm.

We will suppose that we carry out the process on a multi-head transfer machine – type Lanico type BF 280 Ae or similar -, in it the notching and flanging operation is simultaneous. Therefore the stages in the manufacturing are:

– Tube formation on welding machine

– Creasing and flanging of the body on Lanico machine

– Placement of the bottom of the container on machine Lanico

– Placement of the dome of the container on lanico machine

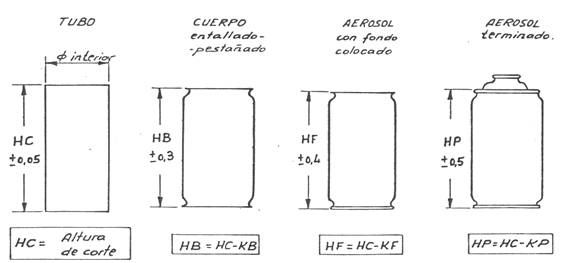

All this according to the sequence indicated in drawing no. 2.

Figure nº 2: Evolution of the heights in an aerosol container

This drawing also indicates the formula that determines the resulting height in each case – HB, HF or HP – depending on the initial cutting height – HC – and taking into account a constant – KB, KF or KP – that reflects the loss of corresponding height

It will therefore suffice to know the values of KB, KF and KP to determine the loss of height in each stage.

For the specific case that we have defined the values of these constants are:

KB = 3 mm

KF = 3.3 mm

KP = 3.6 mm

As we have already indicated, they can vary slightly when the mentioned factors change.

0 Comments