Seaming is a critical process in the manufacture of metal cans, as it ensures that the can is properly sealed to maintain the freshness and quality of the product inside. Next, I will provide you with relevant information about the sewing process and the machines used in this process.

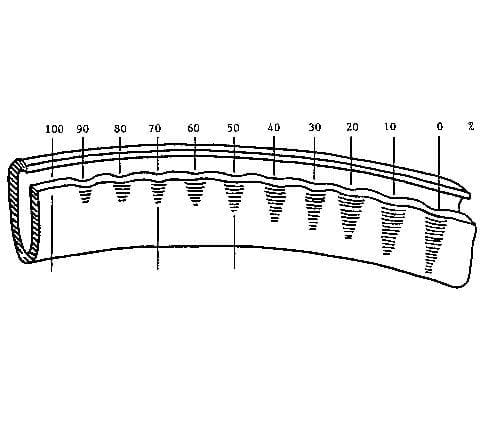

In canmaking, the seam refers to the joining of the lid (or bottom) to the body of the can. This is achieved through a process called double stitching, which involves two main operations: the first operation and the second operation.

- First operation (1st op): During this stage, the lid is placed on the can body and fed into the sewing machine. The first operation wraps the rim of the lid around the rim of the can body, creating a temporary hook. This hook is called the “first operation seam”.

- Second operation: In this stage, the seam from the first operation is flattened and hermetically sealed using second operation rollers. The result is a tight and secure double seam that protects the contents of the can.

The machines used in the sewing process are called sealers or seamers. These machines come in different sizes and capacities, depending on production needs and the types of cans being manufactured.

It is important to note that the quality of the seam is crucial to ensure the integrity of the packaging. Seam defects, such as split seams (also called “clam shells”), can compromise the quality of the packaged product and cause problems in the supply chain. Therefore, it is essential to perform visual inspections and quality tests on seams to ensure that the required standards are met.