4th delivery CLOSING THEORY

13º.- ANALYSIS OF THE CLOSINGS

It is necessary to implement an analysis system, based on the periodic data obtained in the monitoring of the work of a seamer. If the seamer is perfectly adjusted, any significant change in sealing quality is likely to be due to the bodies or bottoms rather than the machine itself.

At present, there are many different types of seaming machines in use.

different types of seaming machines

from those with a single sealing head to those with 16 heads or more. It is essential that the closing process is stable, in all the heads, requiring a rigorous control of the process of each head.

By setting up a trend analysis, supported by the daily representation of the sealing results, it is possible to establish, for each type of seamer, the necessary frequency of the adjustment actions by targets. Well-designed and built seamers may need a target adjustment every three months, while others may need a weekly adjustment.

In the case of irregular container seamers, the target setting process is generally not as accurate, due to the limitations within the design of this type of machine. However, the same principles can be applied.

In general terms, the following principles can be applied to properly follow the evolution of the seams in a seamer:

1.- A sample should be collected at regular intervals, normally one from each sealing station, marking its origin.

2.- Each container is subjected to the measurements and approvals indicated above, noting the results obtained.

3.- The results of the measurements must be compared with the data marked in the specifications. For this purpose, the average of all measurements must be determined, taking into account the maximum and minimum values, comparing this average value obtained with the specifications, as well as its range of variation.

4.- The results obtained must be compared with those obtained from other previous samples, in order to check the state of the machine and to be able to correct its maladjustments without having to stop the machine.

5.- If it appears that the seal is out of control, it is advisable to check 5 containers per station to ensure that the values previously obtained are true.

6.- It is also important to carry out an evaluation of 5 containers per station, when starting to work after a long stop, after a change of format, or even when changing tools on the machine.

If the comparison of the measurements show that the machine is getting out of adjustment, or the seals obtained are progressively moving away from the specifications, this may be due to one of the following causes:

a.- Any change in the characteristics of the bodies or bottoms with which the equipment is fed.

b.- Dirt in the machine.

c.- Excessive wear of any part of the seamer.

e.- Any interference or jamming of the machine mechanisms.

It should be emphasized that the

statistical control of closures

The statistical control ensures greater efficiency and gives us a clear indication of when to act on the regulation and adjustment of the seamer.

In a multi-head seamer, the task of frequent monitoring of several containers per head is a long and laborious task, but it is worthwhile, especially if the machine has been equipped with new technology tools, which are expensive; it is a contradiction in terms to make this expense in order not to have the machine well adjusted at all times through this frequent monitoring.

14º.- SEAMER MAINTENANCE PROTOCOLS

The main maintenance task, by far the most important, is proper lubrication. The most vulnerable areas of the seamer are the parts that move at high speed such as the spindles of the mandrels, compression plates, rollers and the bottom feed system.

The mandrel shaft and the compression plate shaft are particularly susceptible to seizure, not only due to lack of lubrication, but also due to product contamination, in the case of seaming machines in canning factories.

After each production, sufficient time should be spent cleaning vulnerable areas where product spillage may have caused mechanical damage or localised frictional heat generation. Once the pressure washing process has been completed, it is important to grease the bearings to ensure that the trapped water, and in particular the cleaning liquids, are removed to ensure that they do not contaminate the sensitive areas, such as the

roller bearings

. It is ineffective to develop a target setting if it is an obsolete machine, with corroded vulnerable areas. This can often occur on seamers that have only seasonal production.

Seamer builders make engineering efforts to reduce the frequency and proper maintenance of the greasing task. However, oil recirculation systems and self-lubrication systems for the rollers only exist in modern equipment. Many of the old seaming machines, which still work perfectly, need the necessary care and attention to keep them in good condition, and to be able to produce good quality seams.

15º.- TECHNICAL IMPROVEMENTS AND EVOLUTION OF THE CLOSURE (MINI CLOSURES)

Introduction

The arrival on the market of high speed seaming machinesThe reduction of tinplate thickness and the increase of its hardness, the introduction of double reduced tinplate, the generalization of the use of “two-piece” type packaging, and the increased use of closure components made of other materials such as TFS or aluminium, have led to the updating of the closure concept.

In reality, it all stems from the growing need to reduce packaging costs, leading to continuous improvements and modifications in the manufacturing processes of bodies and bottoms. A very significant development in the field of cylindrical cans is the “two-piece” DWI container, i.e. the

can formed by deep-drawing and subsequent stretching and pressing of its walls

. Its great diffusion in the field of carbonated drinks and beer, implies the additional requirement that the closures have to be hermetic subjected to certain internal pressure, so that it does not reproduce loss of carbon dioxide gas.

The obvious advantages of this change are the elimination of any side seams and the need for a single fastener between body and lid. Irregular cans, obtained by shallow drawing, have also benefited from this new manufacturing technology.

Another major breakthrough has been the significant reduction of the thickness of the bottom and body. The use of thinner and stronger materials saves metal, and with the introduction of double-reduced steel, the properties of the containers can be maintained.

This evolution has required the introduction of the “mini closure” technology, which ensures the maintenance of the closure forming process with the new thinner and harder materials. This sealing is also made possible by the facilities offered by three-piece or deep-drawn containers with electrically welded seams. Obviously, a smaller fastener means a higher degree of precision than normal-sized fasteners. However, if we want to correctly implement the use of very thin and hard materials, it is necessary to switch to the techniques of using the “mini seal”, to maintain the minimum level of critical sealing parameters. This brings with it the need to train mechanics and people involved in the conventional sealing technique in this new technology.

Evolution of the closure

Over the last decades, container bodies and bottoms made of coated steel(tinplate, TFS, TFS…), have been optimised by users (e.g. improvements in handling, storage, process conditions…), and packaging manufacturers (e.g. improvements in the manufacturing process, thicknesses, properties…), taking into account the use of thin materials combined with high hardness (e.g. the use of double reduced tinplate).

The use of thinner and stiffer thicknesses for the manufacture of bottoms has directly affected the quality and integrity of the sealing processes. The size or type of closure that was defined and adapted, many years ago, for the use of simple reduced tinplate, thicker and softer, is not necessarily adequate to guarantee a good quality of closure when using a hard and rigid sheet.

As a result, the size or type of closure has not evolved in parallel with the change in the specifications of the container body and especially its base. When applying with these materials the dimensional criteria of the types of fasteners in force, they generate a series of problems, being the main one, the presence of an excessive level of wrinkles, which is a detriment of the quality of the fastener.

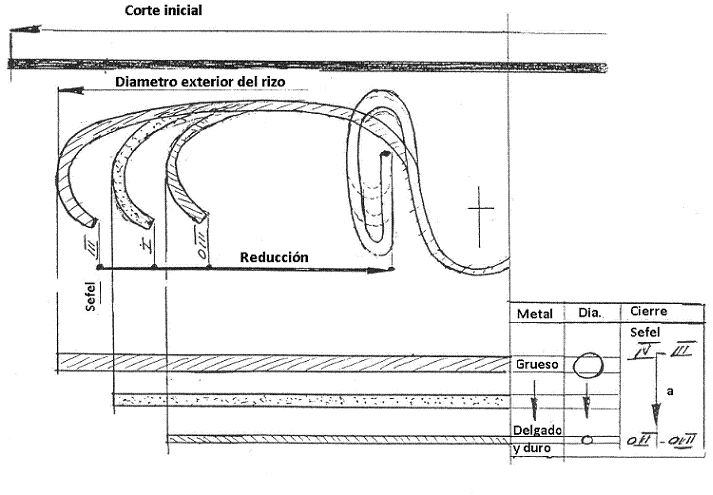

During the closing process, the metal of the flange part of the bottom is “reduced”, and this operation is more pronounced the more peripheral the point is, being maximum at the edge. Thus point “A”, see drawing no. 63 moves from position 1 in its initial state on the cut flat disc to position 2, when the bottom is already curled. Finally it moves to position 3, once the closing is completed.

Figure nr. 63: Evolution of the metal in the wing of a bottom

In this “reduction” process, there is a “leftover” material caused by the decrease in diameter. The natural tendency of metal is to form wrinkles. While these wrinkles can be minimized or eliminated by applying a greater squeeze during the sealing process when using “soft” sheet metal, there will be more and more difficulty, regardless of the type of sealing roll used, when using thin, hard metal. This difficulty will increase significantly in the case of small container diameters, affecting the integrity of the closure. Therefore, in order to eliminate the very serious problem of excessive wrinkling with hard and thin materials, it became necessary to rethink the classic criteria for a closure.

The only possible solution is to reduce the amount of metal of the bottom flange to be “reduced”, by resizing the size of the closure, according to the new specifications of the body and bottom of the container. In short, the decrease in thickness and increase in hardness of the body material and especially of the bottom, forces to redesign the body flange and the bottom flange, going to smaller size standards. This has given rise to a new generation of closures designated as “mini closures”.

This increases the range of closure types with smaller sizes. These new types are valid for both thin and hard blades (DR) and thick and soft blades (SR).

Drawing nº 64 shows the evolution of the process of reducing the size of the bottom flange, which has taken place over the last few decades, linked to the use of new materials. This has led to a reduction in the cutting diameter of the initial disc, and consequently a decrease in material consumption, and consequently significant savings.

Figure no. 64: Change in the size of the closure

The use of this type of DR materials affects not only the closure, it is necessary to redesign the bottom profile, modifying elements such as the depth and configuration of the basin, and redefining the shape of the expansion rings of the central panel.

The reduction in bottom thickness and the adoption of double reduced material inevitably requires a smaller radius of the base of the bottom trough and an increase in the depth of the trough to achieve good sealing results. This change reduces the penetration effort of the mandrel into the bottom.

The technique of making “mini fasteners” requires a higher degree of precision than conventional fasteners, the tools to be used must be of better quality, and it is always desirable to use parts (spindles and rollers at least) coated with chromium carbide or titanium nitride. Let’s specify the necessary progress in each closing operation.

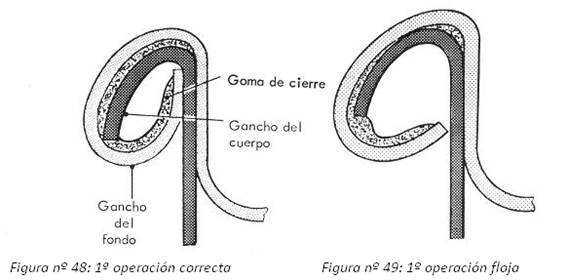

First operation

The correct formation of the first operation of the closure is always the most important factor in achieving good quality. The “mini-zipper” technology requires additional care at the time of the 1st operation, because the harder and thinner the blade is, the more difficult it is to control the presence of wrinkles. Therefore, the design of the profile of this roller is decisive for the success of this step. During the metal forming process, it is essential that the edge of the bottom curl is positioned at the center of the container flange radius. See figure nº 65.

Figure 65: Correct section of the 1st operation of a “mini zip”.

The new reduced design of the bottom flange is such that it contains only the minimum material sufficient to achieve the proper bottom hook length. Therefore, if the 1st operation roller does not have a correct profile, or is defectively adjusted, and does not place the flange material in its exact position, an insufficient overlap will occur at the end of the closure. The alternative of adding more material to the bottom flange to ensure a better bottom hook would have an adverse effect, because it would generate unacceptable wrinkles from the point of view of tightness of the closure.

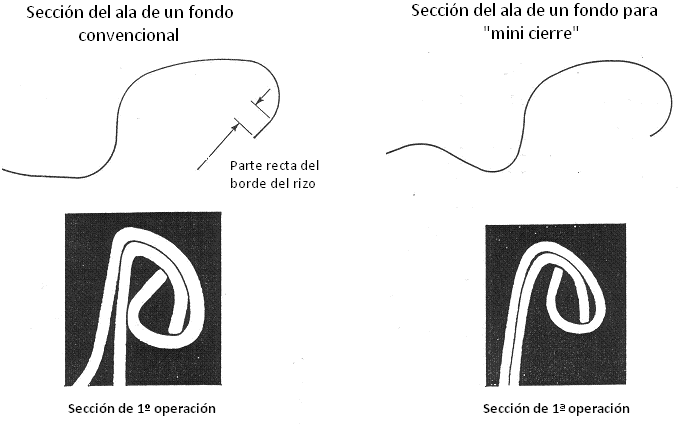

The bottoms designed for “mini closures” present an end or edge of the curl, in which the final straight section has been eliminated, having rounded it up to the cutting edge. Figure 66 shows the straight part of the end of the curl in a conventional background and next to it the appearance that a background of this new type should have.

Figure no. 66: Comparison of a 1st operation in a conventional and a mini-zipper mini lock

On a black background you can see the images of the 1st operations that both types of curls would generate. It is evident that this design gives additional control of the material during the formation of the bottom hook in the 1st operation of the closure.

When we analyze the appearance of the section of a 1st operation, achieved with this new background design, it can be seen that a radical improvement has been achieved using this technology. The material is better controlled and can be placed in the optimum position.

Second operation.

Let us insist once again on the purpose of the action of the second operation: to compress the assembly obtained in the 1st operation, up to a point where the tightness of the seal is guaranteed.

During this operation, the rubber gasket flows to take up any vacuum inside the seal. The profile of the second operation reel, for this type of new bottoms, is designed to meet two basic requirements. First and foremost, your silhouette must be designed to achieve the correct fit to cover the critical parameters of the closure. Secondly, the shape of the profile must try to combine the lowest possible seal pressure with the necessary tightness of the seal.

The new generation of closures, allows to solve the problems generated in the conventional closures, with the increase of hardness and decrease of thickness of the materials, and suppose an advance in the technology of the closure.

Evaluation of the “mini closing”.

The task of performing a “mini-closure” requires a higher degree of precision than a conventional closure, which is why it is necessary to introduce a series of special actions into the typical assessment process of a classic closure, as detailed below.

1st operation:

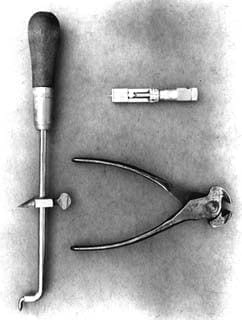

Once the first sealing operation has been carried out by the seamer, it is necessary to evaluate it both dimensionally and optically. The thickness of the first operation is measured and noted with the aid of a hook and loop – or micrometer for fasteners.

In addition, the resulting cuvette depth must be measured after this operation. Therefore, with the gauge already indicated in the section “CLOSURE EVALUATION – Trough depth measurement”, the depth of the trough is measured just at the end of the radius of the trough. Due to the small size and configuration of the seal and the reduction in the size of the bottom flange, it is of great importance to achieve the correct trough depth in the 1st operation.

On the seaming machines that use “non-guided” mandrels and locking rolls, it is necessary to adjust the height of the roll profile in relation to the mandrel lip using feeler gauges, as we have already mentioned. For this type of fasteners it is very positive to use guided roller and mandrel assemblies.

Once these two dimensions have been noted, the fastener obtained in the 1st operation is cut in two opposite points, away from the area of the side seam of the body, and these cuts are observed on the fastener projector. In addition to complying with the specified measures, confirmation that a good geometric formation of the closure has been achieved in its first operation is an important aspect of achieving a good final closure.

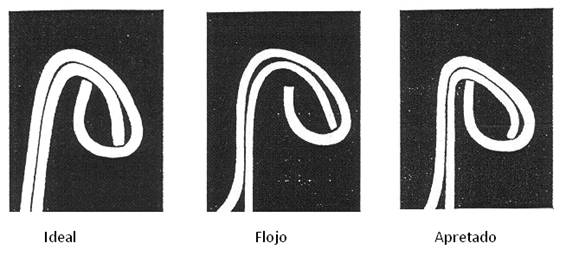

Figure 67 shows three types of a 1st operation of a “mini-closing” which correspond to the following results:

Figure 67: Different types of 1st operation in a mini locking system

Ideal: It is very important that the edge of the bottom curl is seen to be in a position coincident with the center of the body flange radius.

Loose: If the fastener is too loose, an improper bottom hook will be generated.

Tight: If the 1st operation is too tight, distortion will occur between the bottom hook and the body hook.

2nd operation:

As in the case of the 1st operation, it is necessary to assess the seal obtained dimensionally and visually. All dimensions are noted on a process control sheet, from which the critical parameters are calculated.

It is essential that the quality assurance gauges used are capable of measuring “mini closures”, allowing accurate readings. This is particularly relevant for gauges that measure cuvette depth and seal thickness.

Every aspect of the finished closure is important, but critical parameters that must be achieved are essential. The recommended sequence of measures is:

Cell depth:

It is important that the probe of the cuvette depth gauge rests on the area where the cuvette radius ends. Figure 68 shows where the probe should make contact.

Figure No. 68: Measuring the cuvette in a mini-locking device

Unlike conventional bottoms, there is a large dimensional difference between the trough depth and the length of the closure. In drawing 65 it can be seen that the trough in the mini closure is much larger than the closure, different from what occurs in a conventional closure. In many respects this means that adjusting a closer is easier, particularly those using guided rollers and mandrels, where adjustments to correct the relationship between these two elements of the closer is very difficult.

On seaming machines where there is a vertical height adjustment of the rolls, special care must be taken to ensure that the roll is never in contact with the live edge of the mandrel lip. The sophisticated coatings with which most of the sealing tools in this technology are equipped are destroyed in an instant, if there is even a slight contact.

The bottom trough depth is measured at two opposite points after the contents of the container have been emptied, if the evaluation of the closure is carried out in a cannery, as a false reading may result if measured on a container that is under internal vacuum, particularly on bottoms of low metal thickness, which is the normal case in the mini-closure.

Length of the fastener:

Measured at two points, the length of the seal primarily reflects when the tightness of the second runner is snug. In addition, careful monitoring of the seal length is a good indicator of the wear condition of the first runner.

If the second operation roller is set too loose, the length of the finished fastener will be short, e.g. below 2.40 mm. If this roller is too tight, the length of the seal may exceed 2.70 mm. Excessive closing lengths may also be an indication that the 1st operation roller is worn.

Thickness of the seal:

The thickness of the seal is linked to the free space in it, as we have already seen in the concept “Determination of the free space” in section 5ª. EVALUATION OF THE CLOSURE. In the case of the “mini closure“The difference is that the constant is reduced from 0.19 mm. maximum to 0.13, due to the smaller metal thickness and smaller dimensions of the fastener. The expression would be:

Actual seal thickness = (2 Gc + 3 Gf) + 0.13

The body thickness in the

two-piece (DWI) packaging

is difficult to measure, due to the proximity of the transition from thick to thin in the area immediately below the body flange. The packaging supplier should therefore be asked to provide this information. However, the thickness of the bottom must be accurately measured with the appropriate feeler gauge.

The thickness of the closure should be measured at two points, at the 10 o’clock and 14 o’clock positions, where 12 o’clock corresponds to the position of the side seam on three-piece packs, and at two opposite points on two-piece packs.

The process of preparation of the fasteners, sectioning, scrapping, etc., for the mini fastener is analogous to that already discussed for a conventional fastener.

Critical parameters in the mini-closure

Tightening of the fastener:

Undoubtedly the is the most difficult assessment of the acceptability of the fastener, due to the subjectivity of the task of carrying out a visual assessment of the condition of the bottom hook, to establish whether the fastener is quite flat or not.

This is made even more difficult on the “mini zipper”, simply because the smallness of the bottom hook masks and makes it difficult to easily identify wrinkles without ironing.

One of the main objectives of the development of the “mini zipper” was to ensure that the bottom metal deformed during the zipper operation remained under control, thus minimizing the risk of resistant wrinkles formed in the 1st zipper operation, which could be ironed out during the 2nd operation.

However, the thin double reduced (DR) quality material for bottoms requires high sealing pressure to maintain the integrity of the bottom and to match or even improve the performance of conventional bottom seals.

In addition to visual inspection of the bottom hook, we recommend following the instructions below to ensure that the correct decision is made in judging the tightness of the fastener.

Indicators of the tightness of the lock:

1º.- A direct calculation of the space occupied by the rubber gasket inside the seal gives a good confirmation of the degree of pressure in the seal. This area is called ” free space” and for its calculation we refer to what has been said previously on this point in conventional closures.

When the calculation is made for a two-piece can, for the reasons given above, the can manufacturer should be asked for the thickness of the metal of the body in this area (including the varnish) in order to make the calculation.

To make sure that a too tight seal is not responsible for an artificially high result of the clearance value, two more factors must be considered:

First and foremost, it is important to check for evidence of a “springing” of the fastener by looking at a section of the fastener on the projector. In the

figure 69

shows the sympathy between a correct closure and one with “springing”.

Figure No 69: Comparison of locks

Secondly, if the measurement of the length of the fastener is larger than specified for a mini fastener. For example, when it is larger than 2.70 mm.

If the answer was yes to both questions, care must be taken in defining the correct judgement of the sealing conditions, and that wrong information is provided to make a readjustment of the seamer, because if the pressure is increased to reduce the clearance, the result will be worse if the seal was already sufficiently tight.

The evaluation of the degree of pressure or tightness of the mini latch follows the same percentage criteria in relation to the height of the bottom hook as for a conventional latch. The same applies to peaks, wrinkles, folds, etc.

Overlapping or overlapping:

The same criteria must be followed as for a conventional fastener, with the difference that the absolute minimum value is lowered, as a reference 0.9 mm minimum can be taken.

Hook penetration of the body:

The criteria established for a conventional closure are followed.

Visual defects:

The criteria established for a conventional closure are followed.

Influence of the tab

The dimensional specification of the container body flange will have a greater contribution to the good performance of the closure than in a conventional container.

The value of this flange is only slightly reduced for a mini closure, and it is even possible to close containers with conventional bottoms or for mini closures with the same type of flange. However it is inevitable that due to the smaller size of the wing in the latter case, there is less space between the edge of the body flange and the edge of the bottom wing curl. This forces the dimensions of the flange to be more under control, reducing its tolerance range.

If the flange were excessive, there would be an interference between it and the curl, generating flanges bent downwards during the closing operation, which results in false closures. Figure 70 compares the relative positions of the bottom flange and body flange in the case of a conventional container and a container with a mini closure.

Figure no. 70: Curl/tab ratio in conventional and mini-locks

Changes in the production line

The introduction of bottoms made of DR material requires changes in the handling conditions of the bottoms in the can production or filling line. These changes affect both the management and feeding of these funds.

The thinness of the bottom makes it very vulnerable and it can be damaged at different points prior to the closing operation. Damage will inevitably present itself in the form of dents or nicks in the curl of the bottom flange, which experience has shown will result in failure of the double seal if the bottom is not removed from the bottom feed turret of the closer prior to closing. Typical defects are: sagging at the closure, peaks, or residual wrinkles at the bottom hook.

Damage to the forklift, as a result of rolls of bottoms stacked on the pallet, travelling in contact with the mast or forks of the forklift, has been presented as the most common cause of the problem. To prevent these failures, forklift trucks should be modified with a spacer on the forks to prevent contact between the bottom pallet and the forklift mast. See figure nº 71.

Figure no. 71: Spacer placement on forklift trucks

When fitting these spacers, check with the forklift truck manufacturer that shifting the centre of gravity of the load does not affect the stability of the machine.

In addition, forklift operators should be adequately trained, making them understand the vulnerability of the new funds, in the same sense it will be required to implement revisions in the “Operating Instructions” of the plant.

It should be borne in mind that conventional bottoms are more insensitive to these faults due to their greater thickness, which means that this damage occurs in smaller quantities, and even if it does occur, it is transformed into fewer defects on the seal. The bottoms for the mini-closure do not give such a capacity, due to the reduced thickness of the material.

Conclusions:

To recapitulate and at a practical level, we must say that the use of these mini closures allows the use of harder and thinner metals in bottoms, which means a double saving of raw material.

a.- Thickness savings at the same surface area, to maintain its mechanical properties.

b- Savings due to the redesign of the closure, which is reflected in a reduction in surface area.

On the other hand, in order to implement a new closure of this type in a given format, it must be borne in mind that a series of changes must be made that entail a significant cost. The modifications to be established are:

- Reconstruction of the primary scroll coil cutting tooling, according to the new reduced cut of the redesigned bottom. The same applies to the secondary scroll tooling for strip production.

- Renewal of the tooling in presses for the manufacture of the bottom. This affects both the die and the crimper tooling and a readjustment of the gumming machine tooling according to the new outside diameter of the bottom.

- Closers from container manufacturers and fillers will require new change parts for bottom feed as well as closing tooling. That is to say, all the change parts that affect the bottoms need to be replaced or modified (mandrels, rollers, ejectors…), including the bottom feeder which is usually an expensive item.

However, although the initial investment is significant, when it comes to high production formats, the payback period is short.

16º.-PROFITS IN THE TOOLING OF SEAMING MACHINES

In recent decades, equipment manufacturers have focused their improvements in the manufacture of seaming machines, in various areas that we could specify in the following segments:

– Advancement of technology through the introduction of new materials.

– Improved productivity by reducing downtime.

– Improvements in the integrity of the fasteners.

– Reduced operating costs.

We will comment only on the first of them. New materials in sealing technology:

These materials find their main application in equipment where the mini-locking technology is used, as it demands high precision and quality in the tooling.

In conventional seaming machine tooling, the life of the rollers normally exceeds the life of the mandrel by a certain margin. New advances in materials have been made to produce tooling parts (spindles, rollers, bearings) of similar durability.

In this regard, among other new contributions, the following deserve to be highlighted:

A.- Titanium nitride: It is a coating that is added to the tools (spindles and rollers) and that significantly improves their surface finish, reduces damage to the protective varnish of the bottoms and substantially increases the life of the tooling. A paper on this subject has already been published on this website and can be consulted by accessing the page:

Titanium nitride coated locking tools

Figure 72 shows a mandrel coated with this material.

Figure No. 72: Titanium nitride coated chuck

B.- Ceramic bearings for locking rollers: The increase in the life of the rollers, with the use of titanium nitride coating, has had an impact on the use of the bearings used in them. Using a well lubricated conventional quality bearing, a magnitude of 25 million seals can be achieved. With the use of nitrided rollers, a service life exceeding 40 million closures per roller can be achieved. The hourly costs of qualified personnel make it uneconomical to replace the bearings in these partially used rollers. In order to achieve a bearing life comparable to the roller on which it is mounted, a bearing with opposite angular contact was developed, characterized by being made of ceramic balls and a composite material that forms the cage. The inner and outer races of the bearing are made of stainless steel.

With this type of bearing, a significant reduction in the lubrication required has been achieved. Taking into account that many seaming machines need many minutes of downtime per day, working 24 hours a day, the improvement in productivity due to the reduction of lubrication time is evident.

C.- Other materialsFor the closing mandrels there are certain options of materials that tend to lengthen the life of the same in addition to the already mentioned coating with titanium nitride, without going into the detail of the same as its use today is a minority, we can point out:

– Use of a chromium carbide based coating.

– Realization of a mandrel formed by a combined metal/deposited metal material. It has a semi-stainless steel body and a stoody lip.

– Mandrel composed of a sintered metal/ceramic material, combining the properties of both materials.

In short, the aim is to find combinations of materials that improve the resistance and fatigue of the mandrel lip, while also improving its hardness.

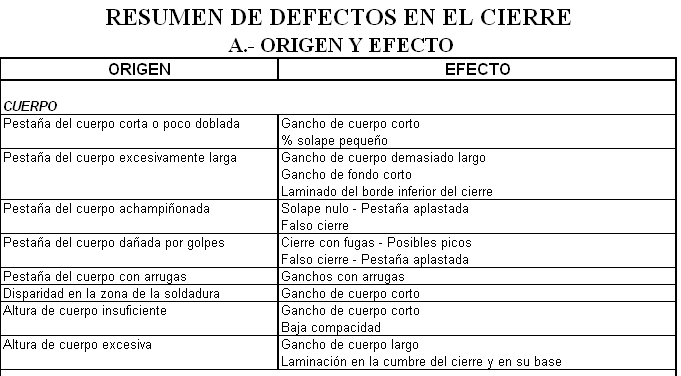

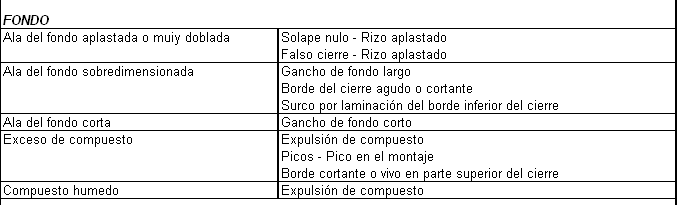

17º.-SUMMARY OF DEFECTS AT CLOSING

There is much that can be written about closure, its possible quality problems, the causes that originate it and the way to solve it, but when a difficulty arises, it is not easy to search through so much literature as to find a way to solve it.

A way of shortening this task is to resort to summary tables where, knowing the defect, they indicate the possible cause, and in this way act in the indicated direction. Or also the opposite, known a possible error or initial imperfection, which effects can generate us in the closing.

Therefore we have prepared the following tables for this purpose.

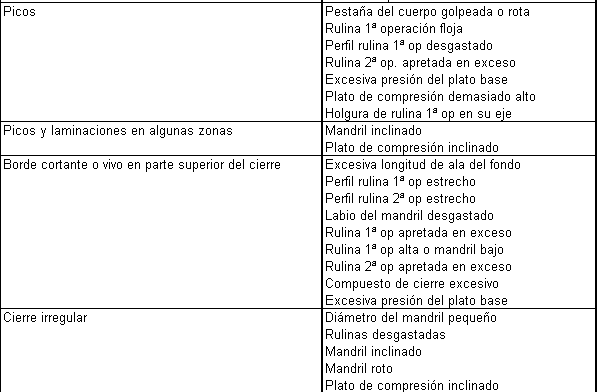

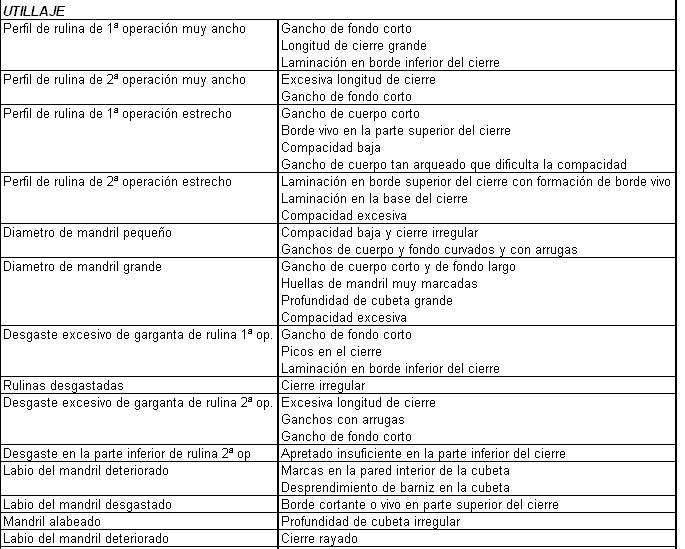

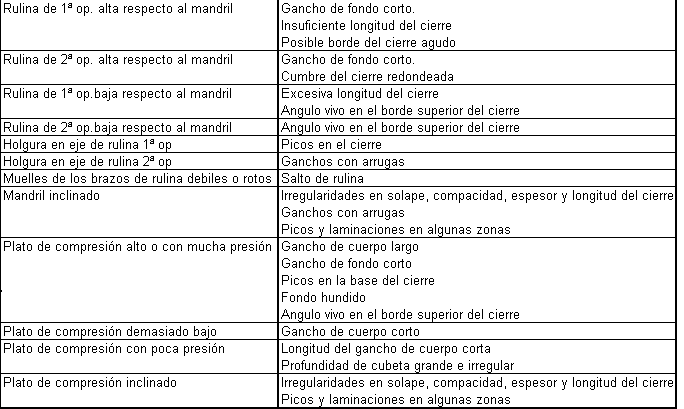

A.-ORIGIN AND EFFECT

If we observe that some of the initial components of the seal, such as: loose bottoms, bodies or empty containers, tooling or adjustments of the seamer, present a previous anomaly and we want to know what it can mean for the seal, the following table tries to summarize in a concise way the different options.

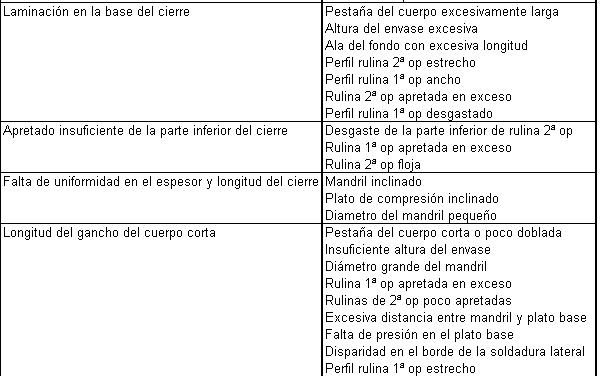

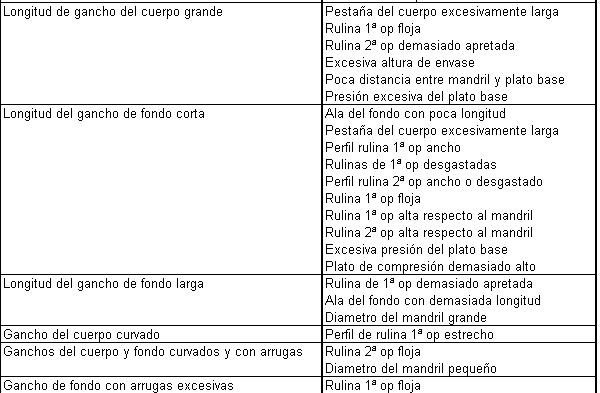

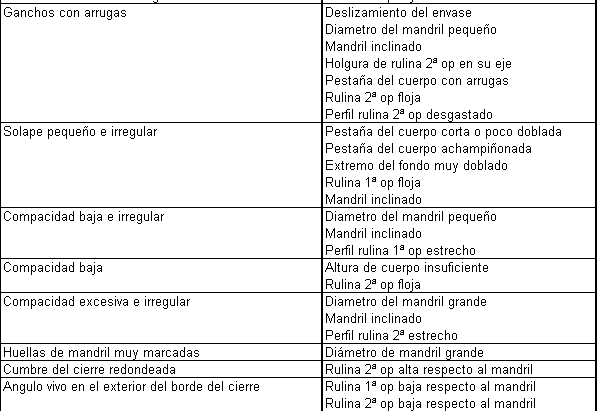

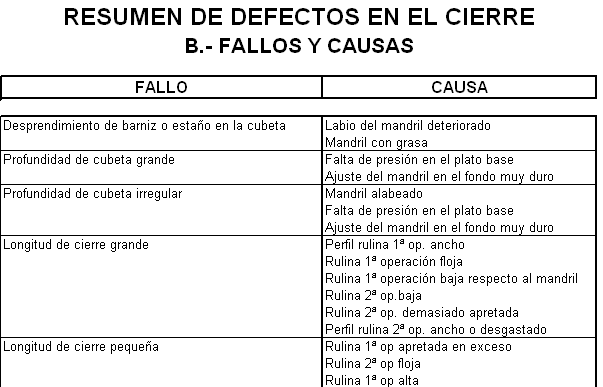

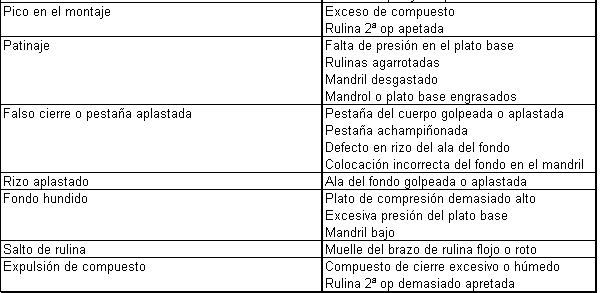

B.- FAILURES AND THEIR CAUSES

The most common situation is the opposite, i.e. when we analyse a fastener we find a particular defect and try to find out its possible origin. The following table responds to this idea.

18º.- SIPNOSIS

As a recapitulation to this work, it can be said that in order to obtain an optimal quality of the seal, and a high efficiency in the sealing operations, it is essential to observe the following points:

a.- Quality of the closure:

For a seal to fulfil its purpose of resistance and tightness, it must have the following characteristics:

1.- The hooks of the body and the bottom must be straight, parallel and of the same length.

2.- The lower edge of the closure must be attached to the body of the container and show no signs of lamination.

3.- The top of the closure must not present edges, sharp angles or signs of lamination.

4.- The top of the fastener should be slightly flat.

5.- The outer curvature of the seal must be uniform and typical of the profile of the second operation roller.

6.- The trough depth should be slightly or moderately greater than the height of the closure.

7.- The compound must cover any gap or free space.

8.- The closure must be uniform along the entire perimeter.

9.- The compactness must be higher than 75% in round containers and 60% in shaped containers.

10.- The degree of tightness must be at least 75% in round containers and 60% in shaped containers.

11.-The overlap must be higher than 45% and in general higher than 1 mm.

12.- The penetration of the body hook must be at least 70%.

b.- High efficiency in the closing equipment.

In order for the seaming machines to function properly and maintain uniform seaming quality, the following must be kept in mind:

1.- To carry out an effective preventive maintenance of the seamer.

2.- Clean and grease the seamer as recommended in the machine manual.

3.- Handle the equipment strictly following the specifications given by the manufacturer.

4.- Use the machine according to the characteristics of the bottoms and containers to be closed, taking into account the ideal type of closure to be used.

5.- Verify that the seamer is producing an adequate quality of closure.

6.- Write down all the operations and adjustments carried out, as well as the results obtained, in order to determine which are the most suitable actions to carry out when similar problems arise again.

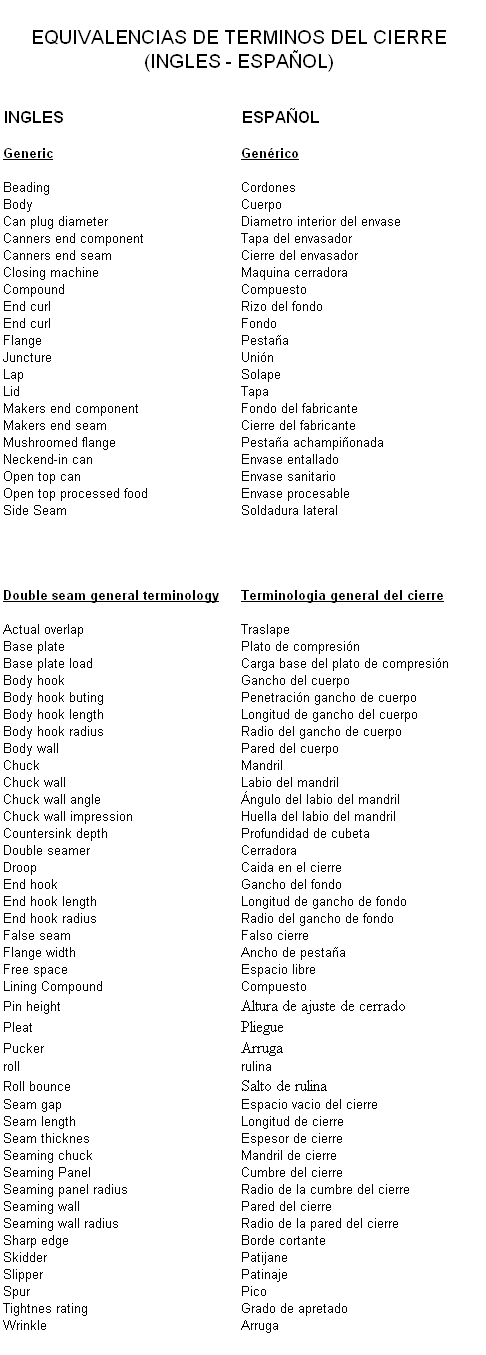

19º.-EQUIVALENCES OF CLOSING TERMS: ENGLISH – SPANISH

The most frequent sources of information on closures are usually written in English, and sometimes it is difficult to find the most appropriate word in its translation into Spanish. That is why we consider it useful, in this work on closures, to include a list of the most common terms in English, with their equivalent in Spanish.

20º.- BIBLIOGRAPHY

– Foodcan “Euroseam” Double Seam Manual by Pete Moran

– Seamer Tooling – IX Seminar on Sealing Technology.

– The sealing of the cans ” by Pete Moran.

– Closing Manual” – Carnaud Packaging.

– Double Seam Manual” – CMB Engineering

– Recommended Industry Specifications for Opon Top Processed Food Cans” – MPMA (Metal Packaging Manufacturers Associaton)

– Closures and Defects of Metal Containers for Food Products” Carlos Paños – Soivre

– Canning of Fish and Meat” by R.J. Footitt and A. S. Lewis

request any roller profiles for seaming of 0.16mm Dr8 body with 0.18mm SR ends .