painting for metal containers

Coating options for metal packaging in general include mainly two types of coatings: liquid coatings and powder...

How to remove wrinkles in the double seam?

To eliminate or reduce wrinkles in the double seam, you can follow these tips: Adjust the roll pressure: Make sure...

what analyses are performed for varnishes

In order to evaluate and approve coatings used in the coating of metal containers, several analyses and tests are...

The TFS material reacts to the copper sulfate test ?

TFS (Tin Free Steel) is a type of steel coated with a layer of chromium instead of tin. The copper sulfate test is...

ANALYSIS OF VARNISHED TINPLATE IN CURRENT REGULATIONS.

In recent years, varnishes applied to tinplate for the manufacture of containers and lids have become increasingly...

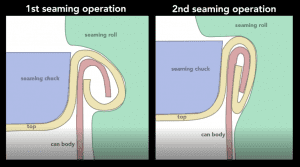

HOW TO FIX DOUBLE SEAM WRINKLES?

To fix double seam wrinkles, you can follow these remedies based on the potential causes: Clincher or first operation...

How to eliminate reverse wrinkle

To eliminate reverse wrinkles in double seams, you can follow these steps: Adjust the 1st operation roll: Reverse...

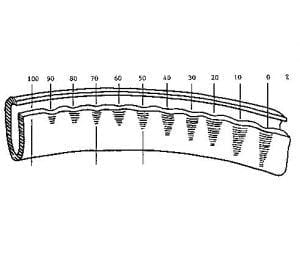

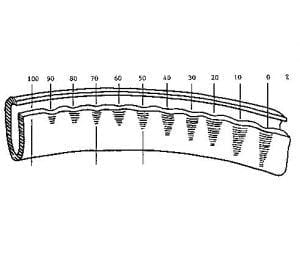

What are the causes for Vees forming in the cover hook

Vees are irregularities in the double seam due to insufficient or no overlap between the cover and body hooks. They...

displaced wing in aerosol background stamping

The occurrence of displaced wings in the printing of aerosol bottoms may be due to several factors. Here are some...

Recommendations for can coatings

Varnishes play a crucial role in the protection and decoration of metal cans. Here are some recommendations for...

Necking Wrinkles: Causes, Consequences and Solutions

Introduction The manufacturing process of metal containers involves a series of stages that seek to give shape and...

Tinplate manufacturing process

Introduction Tinplate is a widely used material in the metal packaging industry due to its unique properties, such as...

What is the electrostatic powder coating layer in can welding?

Electrostatic powder coating in can welding is applied to protect the weld zone and prevent metal exposure. Here are...

Relationship between Tinplate Roughness and Varnish Application

Introduction Tinplate is a material widely used in the manufacture of metal containers, due to its properties of...

The easy open lid comes out open after the autoclaving process, what can it be?

There are several reasons why easy-open lids may come out open after the autoclaving process. Here are some of the...

what is the yield strength of steel?

The yield strength of steel is the point at which a material stops behaving elastically and begins to deform...

what are the technical characteristics of tinplate?

Tinplate is a thin steel material that has been coated with a layer of tin to protect it from corrosion and oxidation....

what is WIMA WELDING?

WIMA welding is a resistance welding technique used in the manufacture of metal packaging. This technique was...

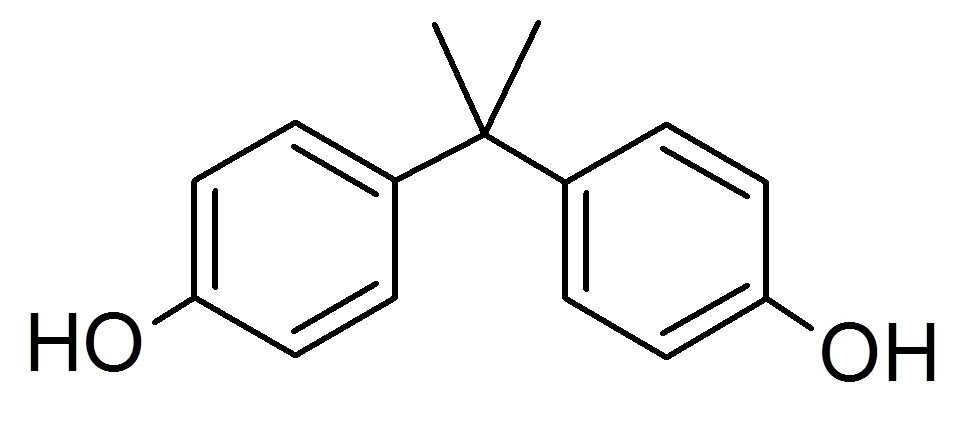

what is BPA?

BPA is the abbreviation for Bisphenol A, a chemical compound used in the manufacture of plastics and resins. BPA has...

What is BADGE?

BADGE is the abbreviation for Bisphenol A diglycidyl ether, which is a chemical compound used in the production of...

what is an epoxyphenol varnish?

An epoxyphenolic varnish is a type of coating used to protect and decorate metal surfaces. It is composed of a mixture...

DIMENSIONS OF SEFEL FASTENERS

The dimensions of SEFEL closures are very important to ensure the quality and safety of light metal packaging. The...

what standards apply to tinplate containers?

There are different rules and regulations that apply to tinplate packaging in different parts of the world. Some of...

what is the difference between TFS and tinplate?

TFS (an acronym for Tin Free Steel) and tinplate are similar materials used in the manufacture of metal packaging....

What are the risks of double seam with short hooks?

double seam with short hooks can present several risks in the can sealing process. Some of these risks are: Leaks:...

Tin Sulfuration in Food Cans

Tin Sulfuration in Food Cans: A Detailed Technical Analysis Introduction Tin sulfiding is a phenomenon that occurs in...

Common defects in twist-off caps and solutions for their prevention

Introduction Twist-off closures are a popular type of closure used in the packaging industry, especially for food and...

how long can a double locking tool last?

The life of a double locking tool, either with or without titanium coating, may vary depending on several factors,...

Cans collapse in the autoclave: causes and solutions

Introduction The autoclaving process is essential in the canning industry to ensure proper sterilization and...

Main varnishing defects in tinplate?

There are several defects that can occur during the tinplate coating process. The following are some of the most...

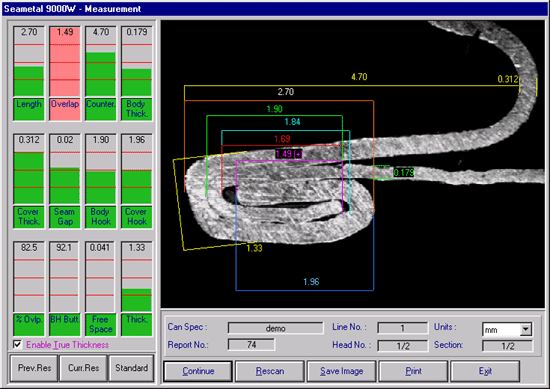

What is the formula for calculating the overlap in the double seal?

The formula for calculating the overlap at the closure of a can is as follows: Overlap = LGc + LGf + 1.1 Gf - Lc...

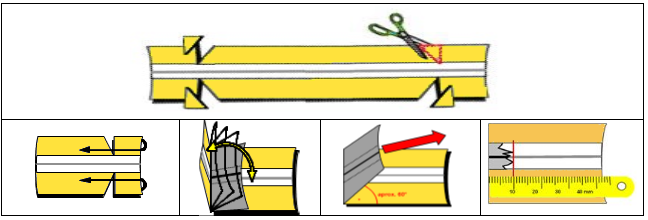

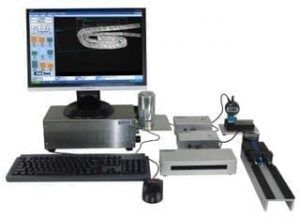

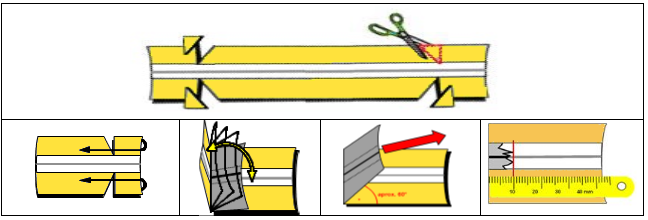

How do I disassemble the double seal for analysis?

To disassemble and analyze the double sealing of a can, you can follow these steps: Cutting and removing the center...

Epoxy Varnish on Food and Beverage Cans: Features, Applications and Benefits

Introduction Epoxy varnish is an essential component in the manufacture of food and beverage cans. Its main function...

BPANI Varnish: Innovation in the coating of food and beverage cans

Introduction BPANI varnish is an innovative coating used in the food and beverage metal packaging industry. This...

Differences between BPANI and Epoxy coatings: a technical comparison

Introduction Varnish is an essential component in the metal packaging industry, providing protection and decoration to...

Fish Tail Defect in Can Welding

Introduction Welding is an essential process in the manufacture of metal cans, since it allows joining the parts and...

The varnish defect called “little eyes”.

The varnish defect called "eyeballing" is a common problem in the metal packaging industry. This defect is...

Twist-Off Caps: Characteristics, Fabrication and Applications

Introduction Twist-off closures are a type of metal closure widely used in the packaging industry, especially on glass...

The Crown Cap: History, Manufacture and Applications in the Metal Packaging Industry

Introduction The crown cap is an essential element in the metal packaging industry, especially in the beverage sector....

Current and future trends in metal packaging

Introduction Metal containers have been a popular choice for preserving and transporting food and beverages for...

Analysis and Solution of Double Sealing Defect: Seam Bumps in Metal Containers

Introduction Metal containers are widely used in the food and beverage industry due to their conservation and...

Metal Packaging Inks: Technologies and Applications

Introduction Metal containers are widely used in the food, beverage and consumer products industry due to their...

3PC PACKAGE, CONTAINERS, EMBUTITION PACKAGING, Frequently Asked Questions, News, PACKAGING, PRINTING, VARNISHING AND CUTTING

Varnishes on Metal Containers: Protection, Technology and Applications

Introduction Varnishes on metal containers play a fundamental role in the protection and preservation of packaged...

Seaming Machines for Metal Containers: Operation, Regulation and Maintenance

Introduction Metal can seamers are essential machines in the packaging industry, as they ensure the integrity and...

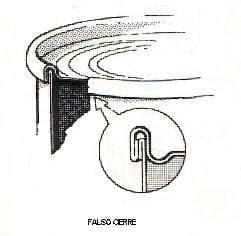

How to solve a false closure?

A false closure can be caused by several factors. To solve it, it is first necessary to identify the cause of the...

What are the causes of leakage in 3-piece containers?

The causes of leakage in 3-piece containers can be varied. Some of the common problems that can cause leakage in these...

What are the critical parameters of the double seal

The critical parameters of the double closure are essential aspects that guarantee the quality and tightness of the...

“Standardization of Canning Plants Using Metal Containers”.

Prepared By: Carlos Herrera Alfaro; Fishing Engineer specialized in the processing of canned food at KIN e.V., Federal...

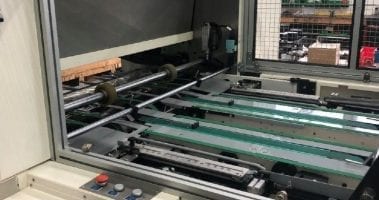

Gaps begin to appear in the print; comparison between Concord and Rutherford

In most cases, this situation is something no can maker wants to see in their Decorator. Almost every can manufacturer...

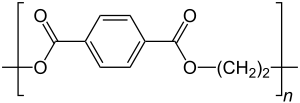

laminated can steel

1. INTRODUCTION For more than 25 years, there have been on the market, for the manufacture of metal packaging, both...

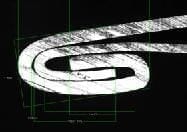

Manufacturing Process for Easy-Open Lids

Introduction:Easy-open closures are key elements in the packaging industry, providing convenience and accessibility to...

How to prevent corrosion of metal cans

Introduction:Metal cans are widely used as packaging for food and other products due to their durability and ability...

varnishes for cans, legislation, technology and purchasing

Trends in can varnish purchases Trends in the purchase of coatings for the metal packaging industry indicate a...

how to reduce dented cans

To reduce dented cans, it is important to consider several aspects of the can manufacturing and handling process:...

classification of impression defects in cans

The classification of printing defects may vary depending on the standard or criteria used by each company or...

corrosion of steel in cans

Corrosion of steel in cans is a process in which steel deteriorates due to chemical reaction with its environment,...

Causes of solder start burn out

Possible causes of burning out the weld start may be the following: Welding current too high: If the welding current...

how tinplate elongation influences the drawing process

The elongation of tinplate is an important factor in the drawing process. Elongation refers to the ability of the...

how the hardness of the tinplate influences the drawing process

The hardness of the tinplate can influence the drawing process in several ways. According to the available...

how does the type of tinplate influence the drawing process?

The type of tinplate used in the drawing process can influence different aspects of the process. The following are...

influence of rerolling on can anisotropy

Rerolling can influence the anisotropy of the materials. Anisotropy refers to material properties and behavior that...

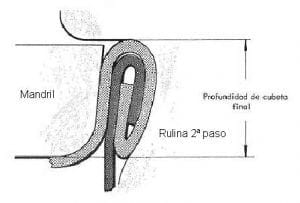

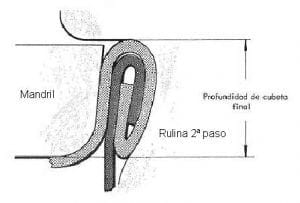

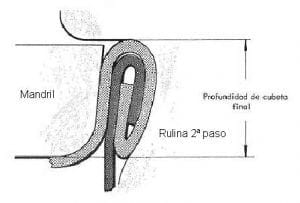

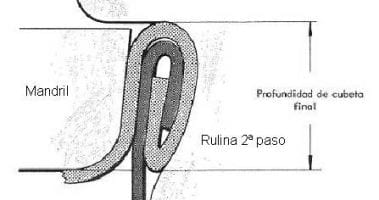

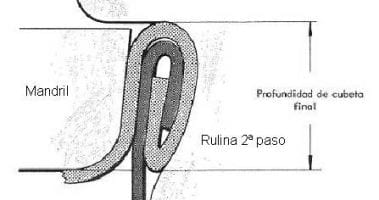

How can I calculate the height of the chuck lip?

To calculate the correct height between the bottom of the mandrel lip and the bottom plate, you can follow these...

how to improve the dosing of electrostatic powder in the welding process

To improve the dosing of electrostatic powder in welding, it is essential to follow some guidelines: Make sure that...

What is the influence of the can flange on the welding process?

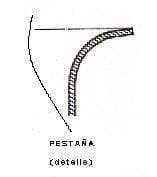

The can flange plays a key role in the double seam process, ensuring that the seam is formed correctly. During the...

Double Seam Thickness Calculation in Cans

To calculate the thickness of the double seam, the following formula is used: Thickness of double seam = 2 * thickness...

How does chloride affect the tfs container?

Chloride, specifically sodium chloride (NaCl), can have a corrosive effect on tinplate containers (TFS). Corrosion can...

equivalence between annealing and tinplate hardness

The hardness of tinplate is related to the annealing process and the base steel used in its manufacture. Annealing is...

Tinplate tempering for food cans

Tinplate can be found in different levels of hardening, which determine its properties and applications. The main...

what annealing has the tinplate type TH

Tinplate type TH (Tinplate Hard) refers to a tinplate material with a hard temper. However, there is no specific...

How to check the seam on a container

To check the seam on a metal container, follow these steps: Visual examination: Perform a careful visual examination...

TIN FREE STEEL (tin free steel) TFS

The name TFS comes from the English words "TIN FREE STEEL", which can be translated as "tin free steel". It is also...

RUST REMOVAL ON CANNING CONTAINERS AND LIDS

In some cases, the industrial process of canning with metallic steel containers can cause oxidation phenomena on both...

Is the roller height related to reverse wrinkling?

Yes, the height of the roll may be related to the reverse wrinkles in the double seam. Reverse wrinkles are formed...

What adjustment should I make if I see creases in the wrinkle?

If you notice creases in the wrinkle of the double seam for cans, you may consider making the following adjustments:...

How to measure the physical properties of a coating

To measure the physical properties of a coating, you can perform the following tests: Varnish film thickness: The most...

measures for checking the closure of a 3-piece container

Verification of the closure of a 3-piece container, such as a tin can, involves inspection of the double seam that...

what material is used for twist off caps?

Twist-off caps are made primarily from tinplate, which is a thin sheet of tin-coated steel. In addition, they use...

can varnish be applied to cover a plate that has already been lithographed with final varnish?

Yes, it is possible to apply varnish on a sheet that is already lithographed and has a final varnish. However, it is...

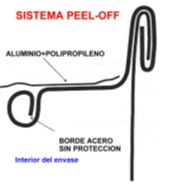

What are the parts of a peel off cover?

A Peel-Off cap consists of the following main parts: Ring: It is the circular metallic part that fits on the rim of...

What is foil used in Peel-Off caps?

The foil used in Peel-Off closures is a thin aluminum foil used to hermetically seal the closure ring on metal...