Introduction:

Easy-open closures are key elements in the packaging industry, providing convenience and accessibility to consumers when opening food and beverage containers. In this technical article, we will explore the manufacturing process of easy-open closures, highlighting the phases involved, the parameters to be taken into account and some possible defects that may arise during the process.

Phases of the Manufacturing Process:

- Cutting: The process begins with the cutting of the metal, which is received in the form of coils with different widths, thicknesses, hardnesses and tin plating. The metal is cut into straight or scroll sheets, with a length determined according to the production line, optimizing waste.

- Manufacture of the Basic Cover: In this phase, circular or shearing cuts are made to shape the basic cover. This is followed by steps such as sketching, incision, molding, riveting and banding. Finally, the incision is re-varnished and palletized.

Parameters to be taken into account in the manufacture of Easy-Open Lids:

- Overall dimensions: The dimensions of the cover, such as the flange, moldings, trough and trim, influence aspects such as sealing, feeding and resistance to deformation. It is essential to take these dimensions into account to ensure optimum performance.

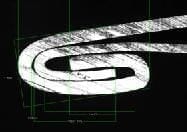

- Incision: The incision must provide ease of opening and, at the same time, resistance during the packaging process and subsequent handling.

- Ring and Rivet: The ring must fit perfectly in the incision, without lifting during the thermal process and be accessible to the finger. The rivet that holds the ring is a delicate parameter due to the deformation it undergoes, which may result in porosity or loss of watertightness.

- Rubber: The proper placement of the rubber and its adjusted weight are important to ensure the tightness of the cover without affecting its parameters.

- Coatings: It is necessary to control porosity, abrasions and feathering in coatings, as they can affect the quality and strength of the cap.

- Attributes: Visual aspects such as stains, pores, bumps, among others, must be considered to ensure the aesthetic quality of the covers.

Quality Control and Measurement:

During the manufacturing process of the easy-open lids, several measurements and quality controls are performed to ensure proper functioning. Some of the parameters measured are:

- Dimensions: Gauges, comparators, micrometers, calipers and automatic gauges are used to measure cap dimensions, ensuring accurate tolerances.

- Opening: Manual and automatic opening tests are performed, as well as measurements of the residual thickness of the incision to ensure smooth and consistent operation.

- Deformations: Implosion resistance, PNR (Peak of No Return), peaks, counter-peaks and ejection are measured to evaluate the resistance of the closure during the packaging and handling process.

- Porosity: Tests such as electrotest, acid copper sulfate and/or autoclave are used to detect possible pores and evaluate the risk of corrosion or attack by the food.

- Attributes: A visual inspection is carried out to detect any visible alteration in the caps, both by personnel and by means of vision cameras at key points of the production line.

Conclusions:

The manufacturing process for easy-open closures is complex and requires attention to multiple parameters to ensure the quality and performance of the closures. Dimensional control, resistance to deformation, watertightness and visual appearance are critical aspects that must be taken into account throughout the process. The implementation of rigorous quality control and precise measurement of parameters ensures the production of reliable and functional easy-open closures to meet consumer needs.