One of the aspects that must be taken into account when changing any of the specifications of a package and/or its components, is that it may affect its physical and chemical characteristics with respect to the packaged products.

If our company has a quality management system in accordance with the UNE-EN-ISO 9001 Standard, this point affects the reference document that affects the design.

ELEMENTS FOR DESIGN. –

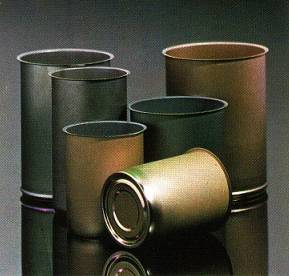

In accordance with the design of the metal containers, the following components of the container are subject to change:

- CONTAINER BODIES

- STANDARD LIDS AND EASY OPENING.

For each of these components, three types of technical requirements will be established, necessary for the correct functionality of the packaging:

- Dimensional requirements, in terms of diameters, heights, and capacities, according to current standards or recommendations to be considered in each case.

- Physical resistance or mechanical characteristics, as an element to withstand the packaging and handling processes until it reaches the final consumer.

- Chemical resistance, appropriate to the requirements of the aggressiveness of the packaged product, and storage conditions.

For each of the previous sections there are a series of elements that directly affect the behaviour of the packaging, in relation to the product to be packaged or the behaviour in its manufacture, handling and subsequent storage and transport.

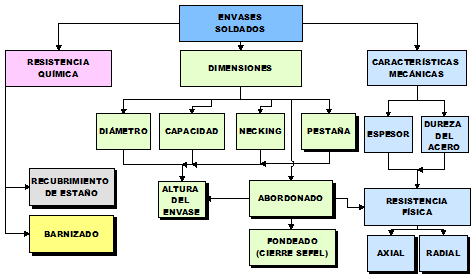

DESIGN OF CONTAINER BODIES WELDING. –

The welded container body is that element of the container, which, starting from a rectangle of tinplate, after being shaped, undergoes welding of two of its opposite sides, creating a cylinder, which, if necessary, can be deformed to create a rectangular body.

- Dimensional requirements: The aspects to be considered for the formation of a welded body are the following: Flange, capacity and height, diameter and taper.

- Chemical resistance: Inner and outer tin coating and type of varnish and amount applied including solder coating.

Physical resistance or mechanical characteristics: Composed of two types of resistance: axial resistance according to the vertical axis of the container and radial resistance, according to the radius of the container, which withstands both process and handling pressures. These mechanical characteristics are determined by three fundamental factors: the thickness of the tinplate used, its hardness (elastic limit) and the profile of the boarding. For economic and legislative reasons, there is a tendency to reduce the thickness of tinplate, which directly affects its physical strength. It is therefore essential to seek to maintain this strength by increasing the hardness of the metal and optimising the boarding.

In stuffed containers, the requirements are similar to those for welded bodies, taking into account that the physical resistance must also take into account the resistance of the bottom of the container to the deformation pressures of this, to avoid irreversible deformation (PNR) or the formation of peaks.

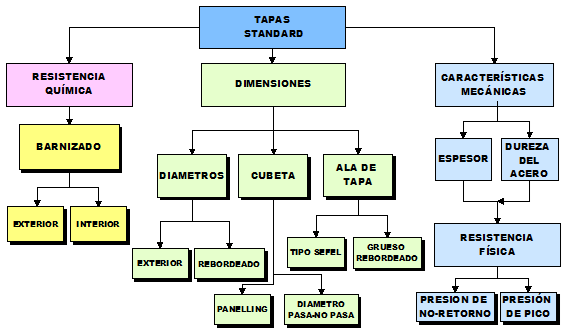

COVER DESIGN STANDARD. –

The lids of the containers are formed from a piece of tinplate, by stamping a tool from a die. It is composed of two fundamental parts, the central panel, which serves as the fundamental bottom and lid of the packaged product and the flange, which is used to make the lid (closure) on the body of the container, and thus achieve the tightness in the closure, essential for the use of containers in food.

We are going to define the changes that can be introduced in the covers, that affect the current design or that make necessary the elaboration of a new cover design:

Material thickness and yield strength, panelling design, lid flange design and types of varnishes.

As for the body of the container, the lids must meet the dimensional, physical and chemical resistance requirements. Each of these sections is affected by a number of elements:

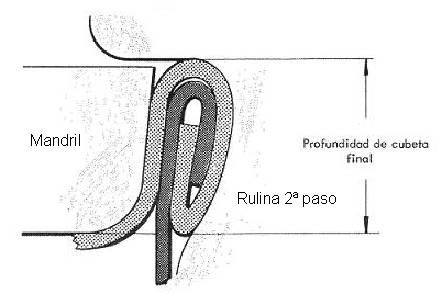

- Dimensional requirements: Outer diameter, flanged inner diameter, flange thickness, trough depth, mandrel diameter and panelling element design and height.

- Physical resistance or mechanical characteristics: It must have a resistance to deformation or pressure of no return (PNR), and resistance to permanent deformation or peak pressure (PP) in which the panelling is irreversibly deformed. As in the case of containers, there is a tendency for the thickness to decrease, due to the same conditioning factors as above, and it must also be maintained by increasing the hardness of the metal and optimising the design of the central pannelling. In this case there is also a problem with the closure of the lid on the container, because a higher hardness of the metal can impair the formation of the closure and this case should be optimized according to SEFEL recommendations.

Chemical resistance: The covers must always be varnished, so the chemical resistance is mainly determined by the type of varnish applied in each case. Externally, the varnish must withstand well a sterilization process in water / steam, and have sufficient mechanical strength to not crack in the processes of machining and closing.

For easy-open closures, the additional requirements are only dimensional, evaluating factors inherent to the closure, such as opening stress, ejection or bursting pressure, or the height of the incision protection cord, which reinforces the resistance of the closure.

The characteristics to be taken into account for the other components of the containers and/or lids, such as varnishes, rubber or electrostatic powder for the inner coating of the weld, are considered in a later work.

José Fco. Pérez Gómez

Mundolatas Advisor

0 Comments