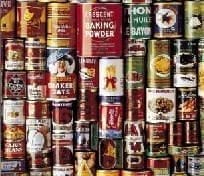

Tin Sulfuration in Food Cans: A Detailed Technical Analysis

Introduction

Tin sulfiding is a phenomenon that occurs in food cans, especially those containing sulfur compounds. This chemical reaction can affect the quality and appearance of canned products, as well as the integrity of the can itself. In this technical article, we will analyze in detail the tin sulfuration, its causes, effects and possible solutions to prevent or minimize this problem in the food canning industry.

- What is tin sulfiding?

Tin sulfiding is a chemical reaction that occurs when sulfur compounds present in food react with the uncoated tinplate surface of cans. As a result, a purple-black tin sulfide coloration forms on the inner surface of the can. This coloration can adversely affect the appearance of the canned product and, in extreme cases, compromise the integrity of the can.

- Causes of tin sulfidation

The main cause of tin sulfuration is the presence of sulfur compounds in canned foods. These compounds can come from natural sources, such as sulfur-rich ingredients (e.g. onion, garlic, cabbage, etc.) or from sulfur-containing food additives. In addition, the canning process itself can contribute to the formation of sulfur compounds, especially if improper processing techniques are used or if there is prolonged exposure to high temperatures.

- Effects of tin sulfiding

Tin sulfiding can have several negative effects on canned products and the cans themselves:

- Appearance: The purple-black coloration caused by tin sulfuration may affect the appearance of the canned product, which may deter consumers from purchasing it.

- Product quality: The presence of tin sulfide can alter the taste and odor of canned foods, affecting their quality and acceptability to consumers.

- Can integrity: In extreme cases, tin sulfidation can weaken the can structure, increasing the risk of corrosion and possible leakage.

- Solutions to prevent or minimize tin sulfiding

There are several strategies that can help prevent or minimize tin sulfidation in food cans:

- Use anti-sulfur coatings: Apply coatings containing zinc oxide in suspension on the inner walls of the can. Zinc oxide binds hydrogen sulfide and is transformed into zinc sulfide, which is colorless and insoluble.

- Proper selection of packaging materials: Use cans with bare tinplate bodies and bottoms protected by a waterproof varnish. This allows the hydrogen sulfide to bind to the can body, while the bottoms are protected.

- Control the pH of foods: In products that have a slightly acidic taste, such as crustaceans, ferrous sulfide formation can be prevented by lowering the pH, through the addition of citric acid, to just below 6.0. However, this does not prevent the formation of tin sulfide.

- Avoid contamination by sulfurated products: Acidic vegetables are generally poor in sulfurated proteins and do not usually produce sulfuration. If the presence of tin sulfide is detected, it is necessary to identify and eliminate the source of sulfur contamination.

- Maintain good manufacturing practices (GMP): Ensure proper handling and packaging of food, avoiding spoilage or fermentation of raw materials and gas production. It is also important to control the handling of containers at reception and production to generate hermetically sealed cans that prevent the infiltration of microorganisms.

- Apply effective heat treatments: Use appropriate heat treatments, defined by a process authority, that give the food stable commercial sterility under normal storage and distribution conditions. It is essential to have suitable equipment and an appropriate standardization of the autoclave bank in the canning plant.

By following these strategies, the formation of tin sulfides in food cans can be minimized and the quality of the packaged product can be maintained.