how do I improve the weld on a container?

To improve the weld on a 610x708 container, several critical factors must be considered based on the information...

Possible causes of leakage in cans at different points of the seam

Leaking cans can be caused by several factors related to the weld and the condition of the can. Some of the possible...

Possible causes of open or cold welds ?

Open or cold welds can be caused by several factors that affect weld quality in metal container manufacturing. Based...

Why can the deficiency of varnish on the inside varnish of the weld be due to a deficiency of varnish ?

The deficiency of varnish in the inner varnish of the weld can be due to several factors. According to the information...

how do i calculate the spring pressure of a can?

The spring pressure on a can seamer can be adjusted and is important to ensure proper seaming. The required pressure...

how to generate a good curing of electrostatic powder for tin cans

To generate a good powder cure in the protection of container welds, it is important to follow a series of steps and...

how to identify if the tinplate is of good quality

To identify if the tinplate is of good quality, there are several factors and procedures that can be followed: Visual...

how to determine the thickness of the tinplate according to the type of metal container

The thickness of tinplate for metal containers is determined by several factors, including the type of container, its...

what is tfs packaging

TFS (Tin Free Steel) containers, also known as chrome plate, are made from a base steel similar to that used in...

the tfs is tinplate?

No, TFS is not tinplate. The name TFS comes from the English words "TIN FREE STEEL", which translates as "tin free...

Manufacturing Process for Easy-Open Lids

Introduction:Easy-open closures are key elements in the packaging industry, providing convenience and accessibility to...

How to prevent corrosion of metal cans

Introduction:Metal cans are widely used as packaging for food and other products due to their durability and ability...

varnishes for cans, legislation, technology and purchasing

Trends in can varnish purchases Trends in the purchase of coatings for the metal packaging industry indicate a...

how to reduce dented cans

To reduce dented cans, it is important to consider several aspects of the can manufacturing and handling process:...

classification of impression defects in cans

The classification of printing defects may vary depending on the standard or criteria used by each company or...

corrosion of steel in cans

Corrosion of steel in cans is a process in which steel deteriorates due to chemical reaction with its environment,...

Causes of solder start burn out

Possible causes of burning out the weld start may be the following: Welding current too high: If the welding current...

how tinplate elongation influences the drawing process

The elongation of tinplate is an important factor in the drawing process. Elongation refers to the ability of the...

how the hardness of the tinplate influences the drawing process

The hardness of the tinplate can influence the drawing process in several ways. According to the available...

how does the type of tinplate influence the drawing process?

The type of tinplate used in the drawing process can influence different aspects of the process. The following are...

influence of rerolling on can anisotropy

Rerolling can influence the anisotropy of the materials. Anisotropy refers to material properties and behavior that...

How can I calculate the height of the chuck lip?

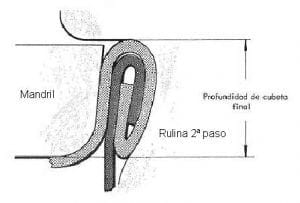

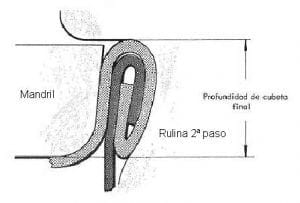

To calculate the correct height between the bottom of the mandrel lip and the bottom plate, you can follow these...

how to improve the dosing of electrostatic powder in the welding process

To improve the dosing of electrostatic powder in welding, it is essential to follow some guidelines: Make sure that...

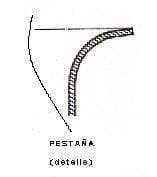

What is the influence of the can flange on the welding process?

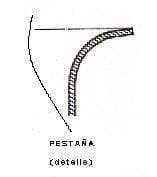

The can flange plays a key role in the double seam process, ensuring that the seam is formed correctly. During the...

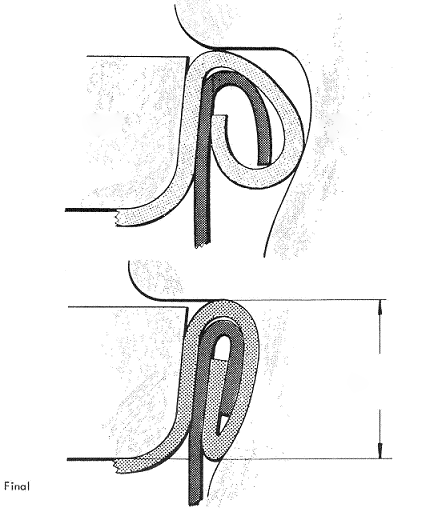

Double Seam Thickness Calculation in Cans

To calculate the thickness of the double seam, the following formula is used: Thickness of double seam = 2 * thickness...

How does chloride affect the tfs container?

Chloride, specifically sodium chloride (NaCl), can have a corrosive effect on tinplate containers (TFS). Corrosion can...

equivalence between annealing and tinplate hardness

The hardness of tinplate is related to the annealing process and the base steel used in its manufacture. Annealing is...

Tinplate tempering for food cans

Tinplate can be found in different levels of hardening, which determine its properties and applications. The main...

what annealing has the tinplate type TH

Tinplate type TH (Tinplate Hard) refers to a tinplate material with a hard temper. However, there is no specific...

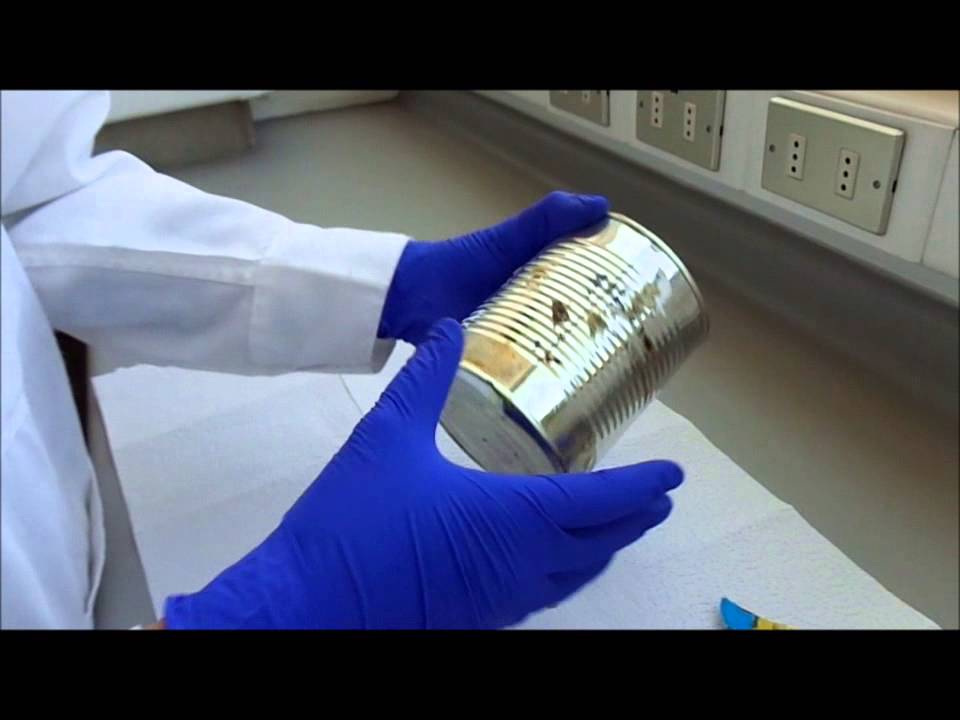

How to check the seam on a container

To check the seam on a metal container, follow these steps: Visual examination: Perform a careful visual examination...

TIN FREE STEEL (tin free steel) TFS

The name TFS comes from the English words "TIN FREE STEEL", which can be translated as "tin free steel". It is also...

RUST REMOVAL ON CANNING CONTAINERS AND LIDS

In some cases, the industrial process of canning with metallic steel containers can cause oxidation phenomena on both...

Is the roller height related to reverse wrinkling?

Yes, the height of the roll may be related to the reverse wrinkles in the double seam. Reverse wrinkles are formed...

What adjustment should I make if I see creases in the wrinkle?

If you notice creases in the wrinkle of the double seam for cans, you may consider making the following adjustments:...

How to measure the physical properties of a coating

To measure the physical properties of a coating, you can perform the following tests: Varnish film thickness: The most...

measures for checking the closure of a 3-piece container

Verification of the closure of a 3-piece container, such as a tin can, involves inspection of the double seam that...

what material is used for twist off caps?

Twist-off caps are made primarily from tinplate, which is a thin sheet of tin-coated steel. In addition, they use...

can varnish be applied to cover a plate that has already been lithographed with final varnish?

Yes, it is possible to apply varnish on a sheet that is already lithographed and has a final varnish. However, it is...

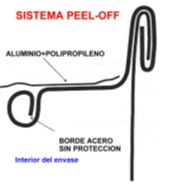

What are the parts of a peel off cover?

A Peel-Off cap consists of the following main parts: Ring: It is the circular metallic part that fits on the rim of...

What is foil used in Peel-Off caps?

The foil used in Peel-Off closures is a thin aluminum foil used to hermetically seal the closure ring on metal...

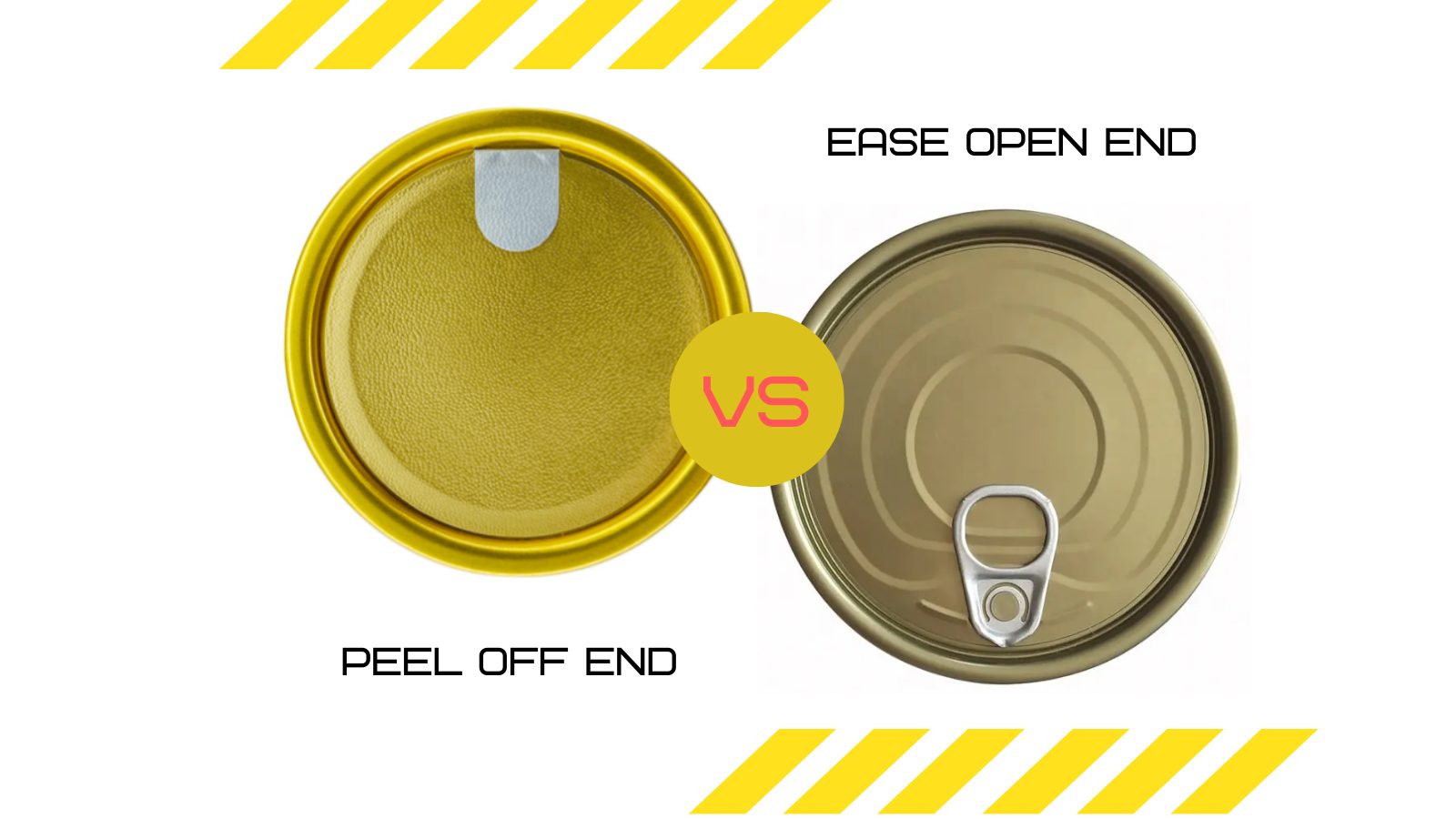

Difference between Easy Open ends and Peel-Off ends

The main difference between Easy Open End (EOE) and Peel-Off Ends lies in their design and opening mechanism: Easy...

Causes of tin can flanges cracked by welding?

Cracked flanges in the welding of metal containers can be caused by several factors. Some of the most common causes...

why the flanges of tinplate food cans are cracked

The flanges of tinplate food containers can crack due to several factors: Use of thin and hard materials: When thin...

blistering or bubbling in the varnish on metal food cans

Blistering is a phenomenon that occurs in metal cans, especially in the weakened areas of the pannelling, where...

what are the steps for the creation of an easy-open tinplate lid?

The steps for creating an easy-open tinplate lid are as follows: Primary scroll sheet slitting of tinplate or aluminum...

Cause of tinplate fracture during deep drawing

Fracture of tinplate during drawing can be caused by several factors. Some of the most common causes are: Unsuitable...

The tinplate stuffing process complies with Hooke’s law.

Hooke's law applies to elastic materials and describes how a material deforms when an external force is applied. The...

Food Can Welding: Process and Technology

Introduction:Welding on food cans is a fundamental process in the packaging industry. Its main purpose is to join the...

Varnishes on Food Cans: Technology, Applications and Trends

IntroductionThe use of coatings on food cans is essential to ensure the quality, safety and durability of packaged...

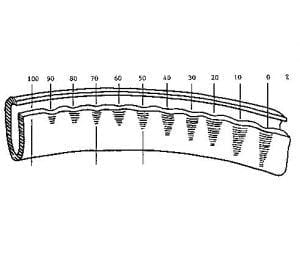

ANALYSIS AND SOLUTION OF THE DOUBLE SEAM DEFECT: SEAM BUMPS

IntroductionMetal containers are widely used in the food and beverage industry due to their preservation and...

Tinplate in the Metal Packaging Industry: Manufacturing Processes and Applications

Tinplate in the Metal Packaging Industry: Manufacturing Processes and Applications Tinplate is an essential material...

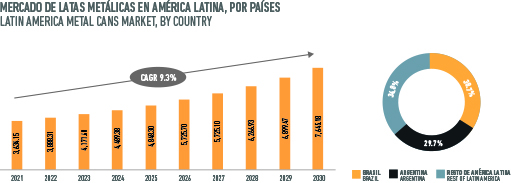

Latin America metal can market forecast to 2030

Brazil accounts for 38.7% of the market share, followed by Argentina with 34%, while the remaining countries account...

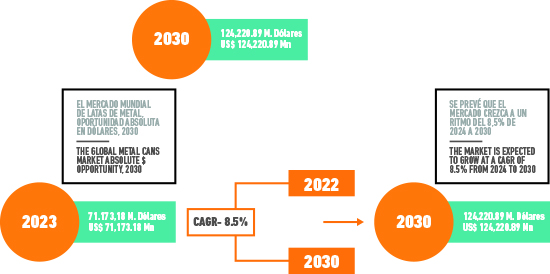

Market Study 2030 Metal Packaging

Market overview Metal cans are containers made mainly of materials such as aluminum or steel, designed for packaging...

Welding on Tinplate Cans

Welding on Tinplate Cans Introduction Brief description of the importance of welding in the manufacture of cans....

Innovations in the Use of Aluminum for Food Preservation

Introduction Aluminum is a widely used material in the food preservation industry due to its excellent barrier...

Coatings for metal containers

Coatings for metal containers include a variety of chemical compounds designed to protect both the contents of the...

Analysis, coatings and physical properties of the lids

Physical properties of easy open lids: Easy open closures, also known as easy open closures, have several important...

How often is it recommended to rectify the welding rollers?

Grinding of welding rollers is a critical maintenance procedure to ensure weld quality in metal container production....

Causes of wire slippage on welding

Causes of wire slippage on the weld in the welding process of food cans, here are some possible causes. Causes of wire...

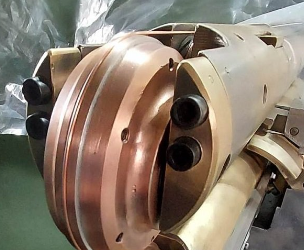

DISCON Welding Rollers at Soudronic

Introduction In the manufacturing process of metal containers, such as three-piece cans, welding plays a crucial role...

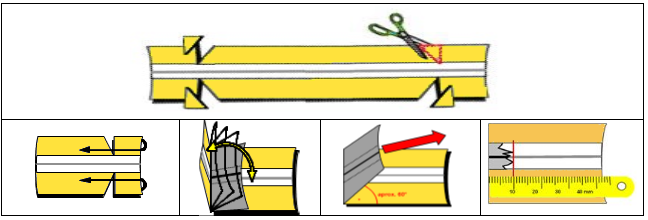

Cutting process in the manufacture of metallic containers

Cutting process in the manufacture of metallic containers The cutting process in the manufacture of tinplate...

How to get a correct rubberizing of a lid

How to get a correct rubberizing of a lid In order to achieve a correct rubberizing of a round cap, it is considered...

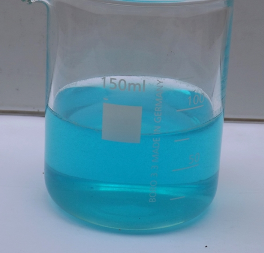

Copper sulfate test in metal containers

The copper sulfate test is a test used in the packaging industry to detect the presence of pores, cracks, or any...

The Blushing Phenomenon in the Manufacture of Tinplate Food Cans

Blushing is a phenomenon that occurs during the manufacturing process of tinplate food cans, specifically during the...

Application, Curing and Main Defects of Electrostatic Powder in 3-Piece Containers

IntroductionElectrostatic powder is a polyester resin used in the metal packaging industry to protect welds from...

can with whitish exterior appearance

The appearance of white spots on the outside of cans may be due to the formation of deposits of dissolved salts,...

how can I improve the double seam of the cans?

To improve the double seam in canmaking, there are several aspects that can be considered based on the information...

can and lid sealing compound

Sealing compound or sealant is a special material that coats the inside of the curl of a can lid. When the can is...

What are the most common dimensions / formats of seafood cans?

The most common dimensions and formats of seafood cans, according to the information provided, include a wide variety...

What are the basic rules for applying sealing compound?

The basic rules for applying sealing compound to can ends are as follows: The weight of the compound should be...

how do I improve the weld on a container?

To improve the weld on a 610x708 container, several critical factors must be considered based on the information...

Possible causes of leakage in cans at different points of the seam

Leaking cans can be caused by several factors related to the weld and the condition of the can. Some of the possible...

Possible causes of open or cold welds ?

Open or cold welds can be caused by several factors that affect weld quality in metal container manufacturing. Based...

Why can the deficiency of varnish on the inside varnish of the weld be due to a deficiency of varnish ?

The deficiency of varnish in the inner varnish of the weld can be due to several factors. According to the information...

how do i calculate the spring pressure of a can?

The spring pressure on a can seamer can be adjusted and is important to ensure proper seaming. The required pressure...

how to generate a good curing of electrostatic powder for tin cans

To generate a good powder cure in the protection of container welds, it is important to follow a series of steps and...

how to identify if the tinplate is of good quality

To identify if the tinplate is of good quality, there are several factors and procedures that can be followed: Visual...

how to determine the thickness of the tinplate according to the type of metal container

The thickness of tinplate for metal containers is determined by several factors, including the type of container, its...

what is tfs packaging

TFS (Tin Free Steel) containers, also known as chrome plate, are made from a base steel similar to that used in...

the tfs is tinplate?

No, TFS is not tinplate. The name TFS comes from the English words "TIN FREE STEEL", which translates as "tin free...