To improve the double seam in canmaking, there are several aspects that can be considered based on the information provided:

- Closing force control: It is important to adjust the closing force correctly to avoid too tight a seal, which can damage the varnish or eject the sealing gum out of the seal. If the closing force is found to be too high, it should be reduced by adjusting the pretension of the springs.

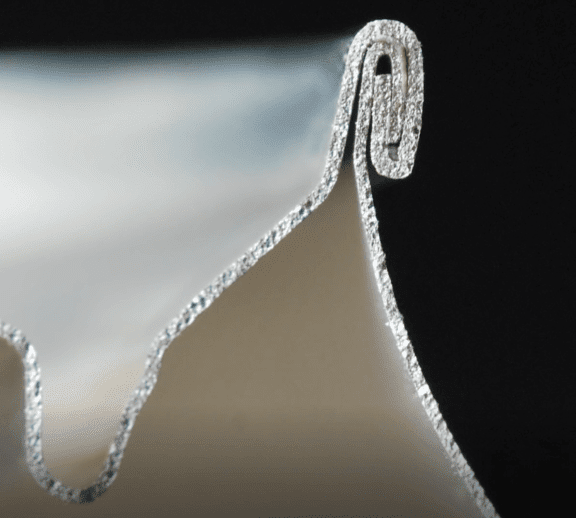

- Material quality: Check the quality and adhesion of the varnish used, as well as the wear of the sealing segments. If the sealing segments are identified as worn, they should be replaced.

- Adequate lubrication: Ensure that there is sufficient oil in the greasing device, as a lack of lubrication may affect the quality of the seal.

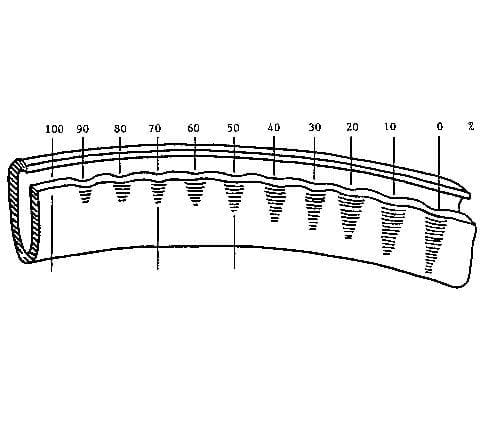

- Visual inspection and measurements: Perform visual inspections and measurements to verify the absence of visual defects and control critical parameters such as percentage of corrugations, overlap, body hook penetration and closure compactness.

- Proper cap handling: Check the cap destacking process to avoid damage that could affect the closure.

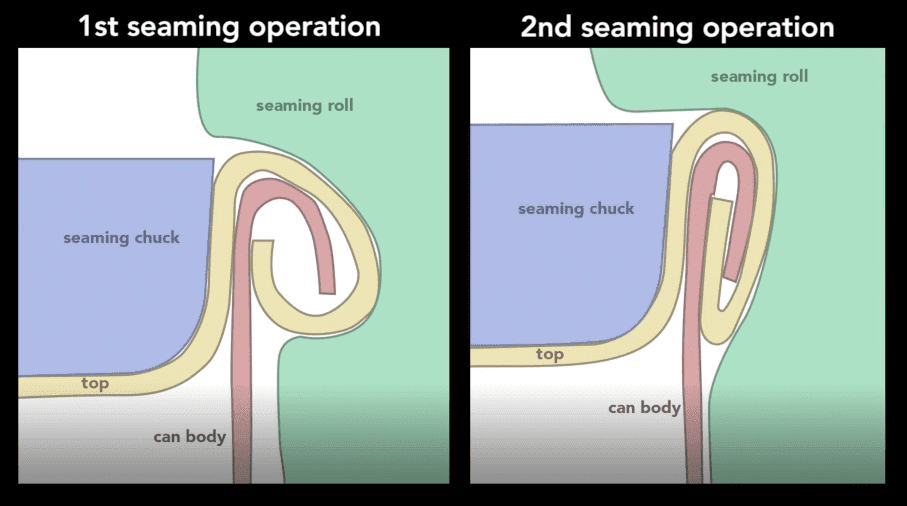

- Roll adjustment: On the roll seaming machines, it is crucial that the 1st and 2nd pass rolls are correctly adjusted to perform the first and second seaming operation effectively.

- Sealing pressure: Especially in the case of thin or double reduced materials, adequate sealing pressure is required to maintain the integrity of the seal.

- Personnel training: Qualified personnel for the adjustment, maintenance and control of the seamers and their tooling is essential for the production of good quality seals.

- Use of measurement technology: Use instrument banks for external measurements and shut-off switches for internal measurements to obtain fast and reliable measurements.

- Immediate reaction to deviations: If any deviation in seal quality is detected, immediate action must be taken to correct the problem.

By following these general recommendations, the quality of the double seam in can manufacturing can be improved.

0 Comments