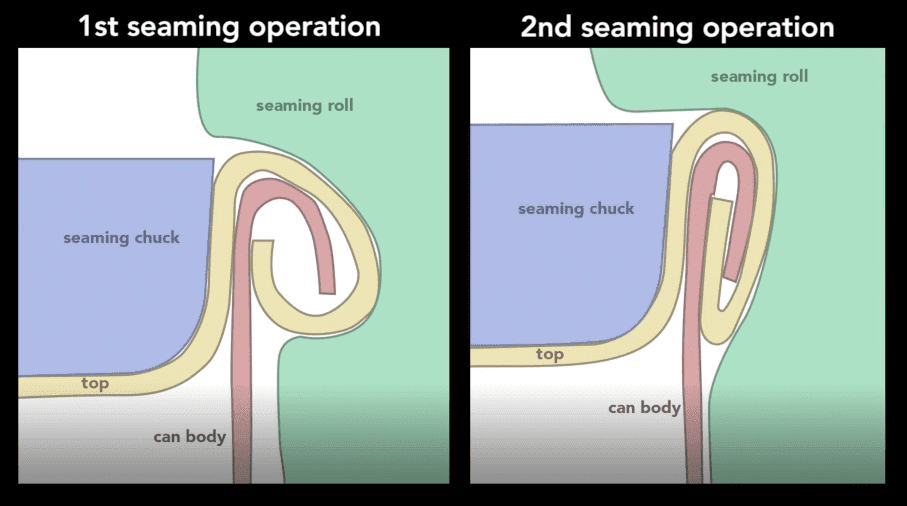

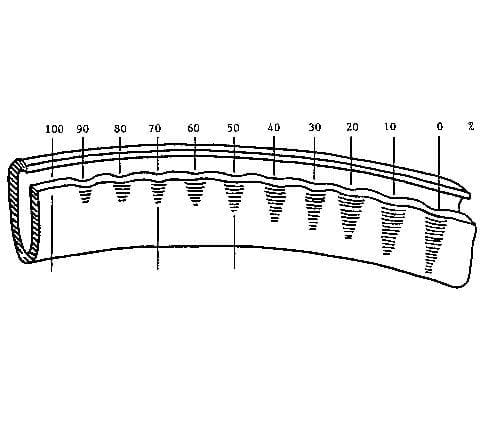

Compactness in the context of container closures, such as double closures, refers to the degree of contact between the layers of tinplate forming the closure. Compactness is related to clearance and is used to evaluate the quality of the seal in terms of tightness and strength. A tight seal will have low clearance and high compactness.

In the case of double sealing, compactness becomes more important as the sealing surfaces are doubled, providing a double sealing barrier. This improves the tightness and strength of the seal compared to simple friction seals.

The compactness can be expressed by the following formula:

Compacity = C = (2 * Gc + 3 * Gf) * 100

Where E is the actual thickness of the closure, Gf is the thickness of the bottom metal and Gc is the thickness of the body metal.

The classification of compactness in a closure can be as follows:

- Very good: C > 85%.

- Good: 75% < C < 85%

- Hazardous: C < 75%

It is worth mentioning that this measure of compactness is valid only for round containers and not for carbonated beverage or beer containers, where the internal pressure is high and requires higher compactness values. In the case of rectangular and oval-shaped containers, which have a somewhat higher composite weight, a minimum compactness value of 60% is acceptable.