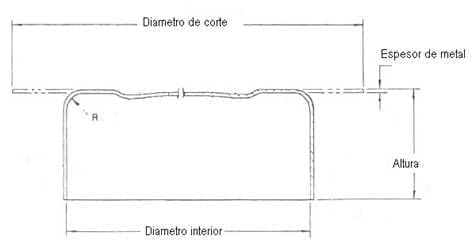

The operation of configuring a Twist-off lid starts by inserting a capsule in the press with the general shape of the lid, the side wall of which is smooth and vertical. In this operation, the central panel of the lid is outlined. See figure # 1

Figure No. 1: Shape of the capsule at the press outlet

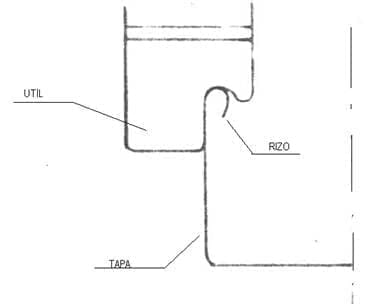

From there the next step is carried out, which consists of preparing the edge of the lid, providing it with a curl to give it consistency, and some nails that allow to fix the lid on the glass bottle.

This operation is carried out in two steps. In the first one the formation of the curl starts inwards. This is achieved by means of a special machine. The basic work organ of the same is a forming head with rulinas, mounted on axes with free rotation, which act on the edge of the capsule obtained in press. By rotating the lid, said edge is rolled inwardly. See figure 2

Figure nº 2: Curl formation

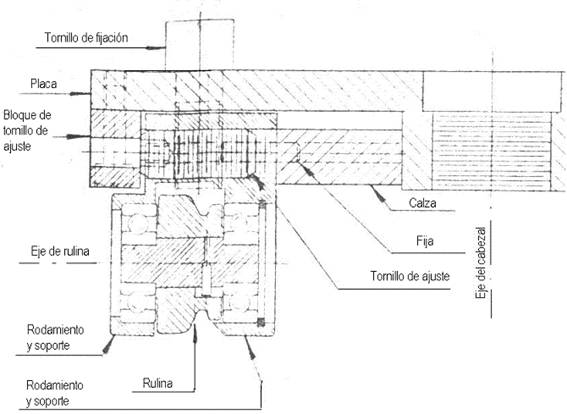

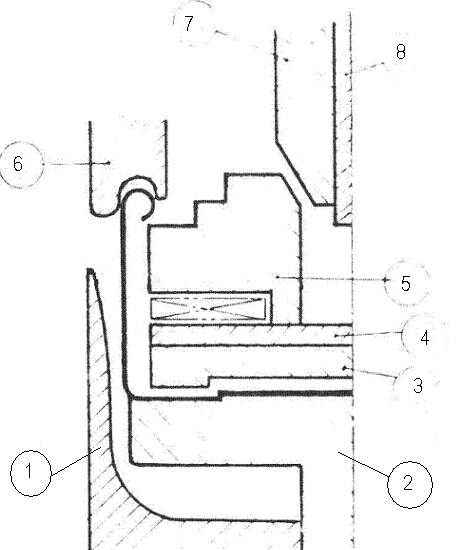

The width of the curl formed is approximately one millimeter. The curling head in general has three curling rollers mounted at 120 °, coupled by means of a pair of bearings with their supports, on a base plate. The assembly of the rulina can be adjusted racially by means of a screw. In drawing no. 3 a vertical section of this head is partially presented

Figure 3: Partial vertical section of a curling head .

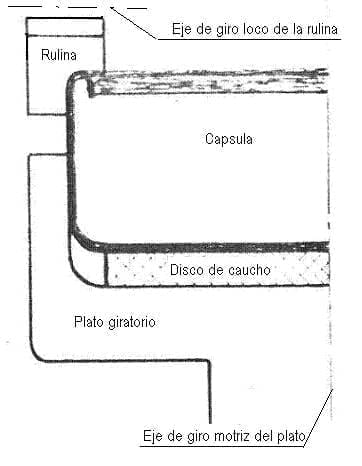

The sequence is as follows: the capsule obtained in the press enters a lower plate, located under the head holder-rulinas, by means of a star mechanism. When raising the plate, while rotating carrying the capsule, the edge of it touches the entrance curve of the throat of the rulinas. As the plate rises, the curl is generated. The capsule should fit on the plate. This is achieved by making the inside diameter of the plate 0.05 mm lower than the outer diameter of the capsule. So that it does not slip on the plate, a rubber disc that increases friction is placed at the bottom of the plate. See figure # 4

Figure 4: Schematic of the curl formation head

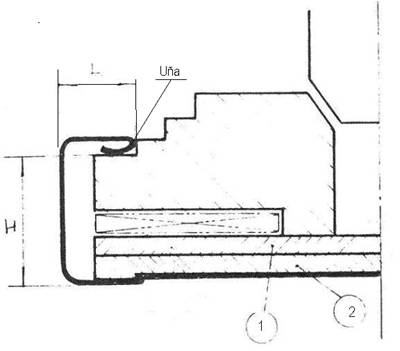

In the next step, which can be located on the same or a different machine, another special spindle ends the operation. See figure nº 5. The capsule is centered on a plate, by means of an external piece in the form of bell (1) The central part of this plate, on which the capsule is deposited, has vertical movement (Piece 2). In its ascent it introduces the cover with the initial curl in a head percutiéndola against a ring that presents / displays a groove (Piece 6), that completes its formation.

Figure No. 5: Initial position of the curl end cap and nail formation

Figure 6 presents a partial section of a lid with its finished curl

Figure 6: Final shape of curl

When raising the cover it elevates the pieces 3, 4 and 5 of the cabezal. In it, a central cone (piece no. 7) acts on some fingers, (pieces no. 5) as many as nails we want the lid to have, expanding them out radially. When finishing to raise the plate, these fingers will crush the curl forming the nails. See Figure No. 7. Before the start of the descent, the fingers contract by means of springs, allowing the lid to exit.

Figure nº 7ª: Final position of the curl finishing head and nail formation

The fundamental measures so that the nails fulfill their function of fitting to the mouth finish of the glass bottle, are H (height to the central panel of the lid) and L (width or length of the nail). If we want to increase the height H, a fine wedge must be placed between pieces 1 and 2 of figure no. 7.

Depending on the desired production speed, one or more curling assemblies can be mounted and the capsules fed by stars or linearly. Figure 8 shows a complete section of the upper part of a curl and nail forming head.

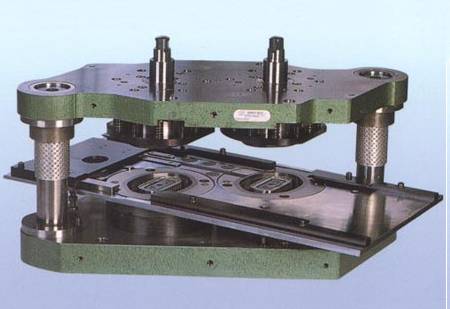

Figure nº 8: Finishing head for curling and nail formation

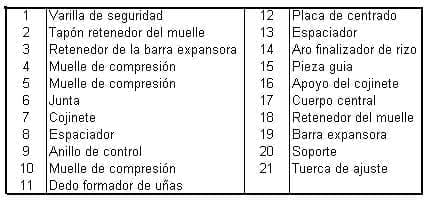

The pieces that form this head are:

The pieces marked * change with the size of the capsule

The next step in manufacturing is to apply the compound inside the lid and bake it properly.

0 Comments