INTRODUCTION

The final quality of a lid, whatever its destination: sketch for easy-opening lids, conventional bottom, etc., depends on three factors:

– 1º.- Material consumed

– 2nd.- Employee tooling

– 3º.- Equipment used

In this paper we will focus on the 2nd point, although only from the perspective of the need to maintain the die that produces these covers in the ideal operating conditions. We will not therefore enter into the aspects of its design and construction, which are also vital.

We have already discussed in another job of this Web the topic of the maintenance of a die for tapas. We refer our reader to the article:

In the second part of it, the procedure to be applied to perform the maintenance of a lid die is described. In truth, this work is a continuation of the aforementioned, and what is proposed is to provide the necessary help to translate into proper documents the realization of this maintenance.

CHECK LIST

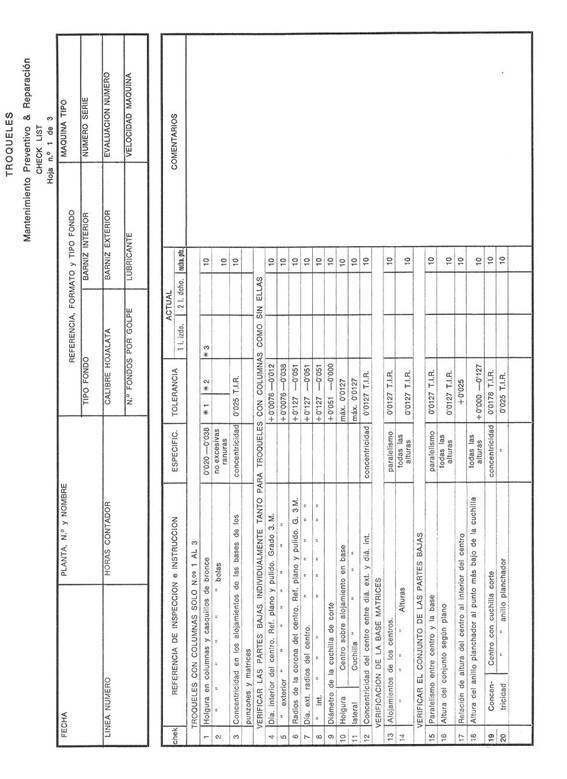

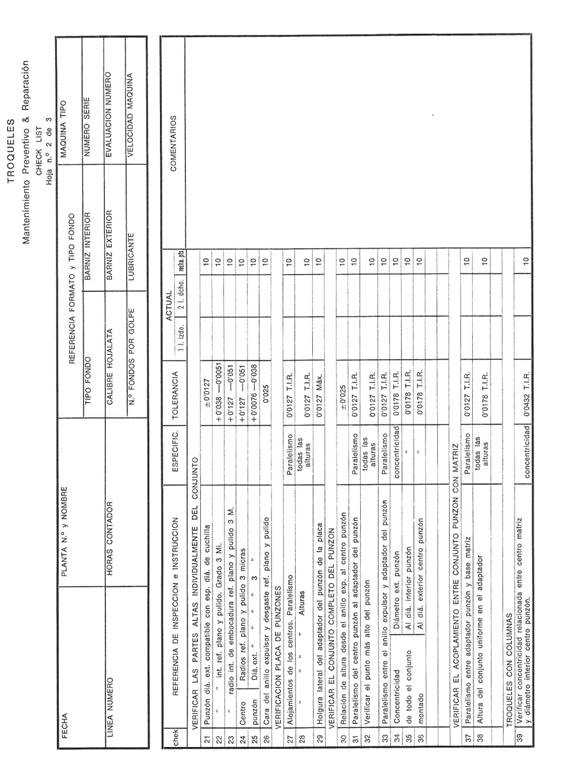

To reflect the results of the maintenance operations described in “Using a lid die”, you must have a checklist with the specifications and tolerances to be followed in each case, and a blank column to write down the values and real situations of the die. This is materialized in a table commonly called “Checklist” – “Chech list” -.

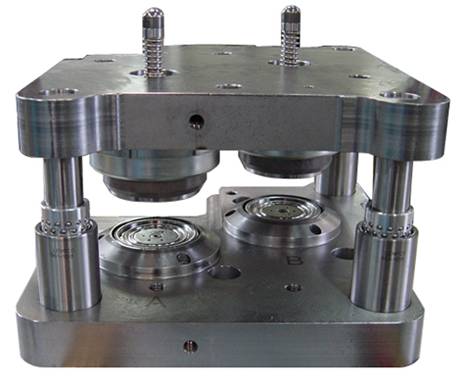

The simplest way to develop a “checklist” is to give an example, therefore, below we reflect a specific case of this document for a die used in the manufacture of conventional caps. We have selected one of the guided type with columns, double punch, which is the most frequent. This document has two parts:

1ª.- A painting, developed in two pages, where it is expressed:

A.- A series of boxes to record the general data: date, manufacturing plant, line, data of the covers, etc.

B.- The actual checklist, where in different columns the initial data are reflected and other blank ones for the annotations of the real values. The starting data include:

– “Inspection and instruction reference”, that is, the part to be verified and which is to be verified.

– The specifications corresponding to the case

– Your tolerances

In the blank columns, the values for each of the two punches and their comments are written down.

See the next two pages.

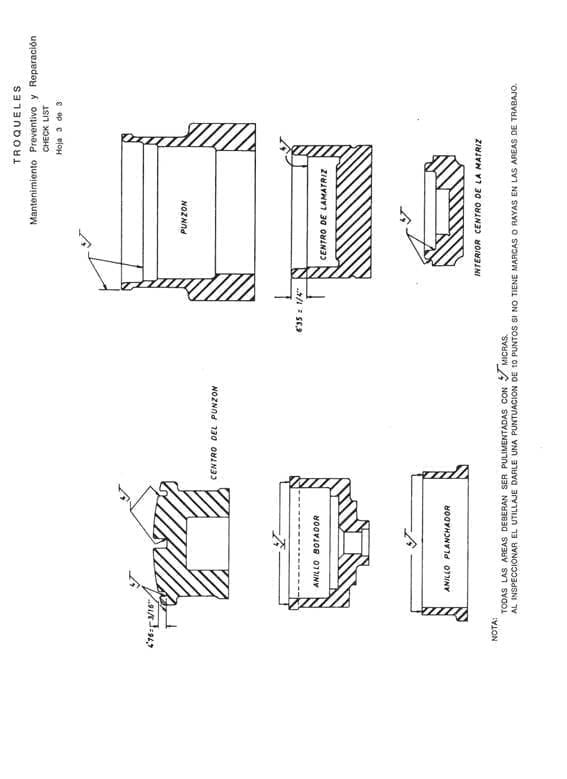

2 .- Drawings of the basic parts of the die, whose surface terminations directly affect the lid to obtain. In these drawings, the degree of finishing that they must present is noted on the critical surfaces. See next drawing:

0 Comments