The sterilization process in the canning industry is a critical step to guarantee the safety and quality of canned products. This process involves subjecting canned products to high temperatures to eliminate microorganisms and ensure commercial sterility. The general steps in the sterilization process are described below:

- Product preparation: Food is prepared and packed in cans. This may include washing, chopping, cooking and canning of the product.

- Hermetic sealing: The cans are hermetically sealed to prevent air ingress and ensure an anaerobic environment inside the can. This is essential to prevent the proliferation of microorganisms.

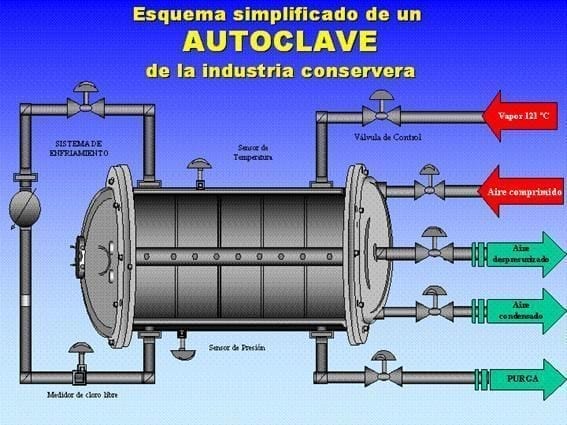

- Heat treatment: Sealed cans are subjected to heat treatment, which generally involves the use of autoclaves or pasteurizers. Conventional direct steam autoclaves, overpressure autoclaves and others are used to apply high temperatures and pressures to cans for a specific time. This process ensures the elimination of microorganisms and the commercial sterility of the product.

- Cooling: After heat treatment, the cans are cooled rapidly to stop the cooking process and maintain product quality.

- Inspection and storage: Once the cans have cooled, they are inspected to ensure product quality and sterility. Cans that pass inspection are stored and distributed for sale.

It is important to bear in mind that the thermal profile and treatment times may vary according to the type of product and packaging. Sterilization must be adjusted to a pre-calculated curve to obtain the optimum nutrient conservation characteristics of the food and the best visual appearance, while complying with minimum time restrictions at high temperature to ensure the lethality of the bacteria present in the product.