The quality of the water used in container sterilization is very important to ensure the safety and quality of the packaged product. In general, the water used in container sterilization should be soft, i.e. have a low concentration of salts and low electrical conductivity. In addition, it is recommended that the pH of the water be between 7.00 and 8.00 and that its hardness not exceed 10 degrees Fahrenheit.

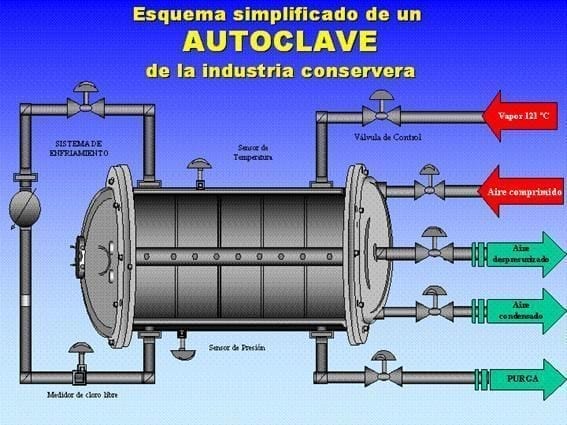

It is important that the water used in container sterilization is adequately treated to avoid the presence of microorganisms that could contaminate the containers. For this purpose, it is recommended that the containers be washed and rinsed with hot water before placing them in the autoclaves. Detergents used for this type of cleaning must be neutral in relation to the containers.

In case the containers are sterilized in water, if this water – treated for hardness – is recycled, it is important to check at regular intervals certain physical and chemical characteristics, in order to control variations concerning water hardness, pH, chloride content, nitrates, etc.

In addition, it is important that the cooling of the containers after the sterilization process is not excessive, since at 40 degrees Celsius, the containers still retain sufficient latent heat for spontaneous drying. Chlorination of cooling water to avoid recontamination of containers after processing should not be a factor favoring corrosion as long as the free active chlorine does not exceed 2 to 3 mg/liter at the moment of use, i.e. at the moment of contact with the containers being cooled. Such content must be kept under control and checked at regular intervals.