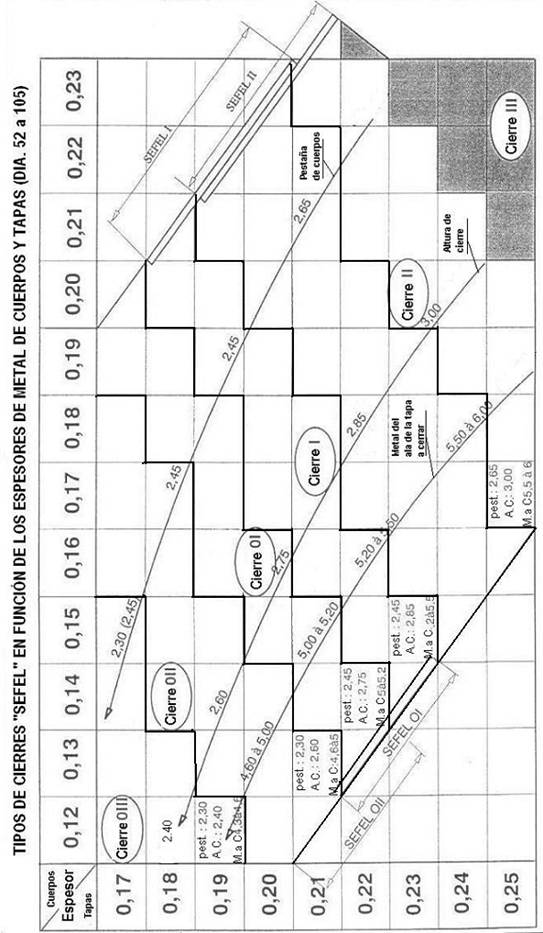

These factors are:

– Thickness of cover metal.

– Amount of flange metal of the flap to be closed

– Body metal thickness

– Body tab (dimensions)

– Metal hardness

Depending on the values of these factors, the ideal dimensions of the closure will correspond to a specific type of closure.

On the dimensions and characteristics of the different types of fasteners there are already several works hung in this Web, now we limit ourselves to present a summary table, where depending on the factors mentioned above, is defined the type of fastener to use.

For the field of each type of closure, the numerical values of the body flange (“pest“), the height of the resulting closure (“A.C.”) and the metal of the flange of the cover to be closed (“M. to C.”)are indicated in this table.

When the container body to be sealed is deep-drawn, it is advisable to add 0.01 to 0.02 mm to the nominal thickness.

0 Comments