IIntroduction to the excellent work “INSTRUCTIONS FOR THE CORRECT USE OF THE TWIST, PT, PT PLUS VACUUM COVERS” which, by courtesy of “CROWN CLOSURES EUROPA”, we have the pleasure to publish.

Crown Closures Europe

INSTRUCTIONS FOR CORRECT USE

OF VACUUM COVERS

TWIST

PT

PT PLUS

The following appendices are attached:

A: External corrosion of the caps

B: Closing and Covering Safety Measures

C: Control procedures in the filling lines

INDEX

0. Basic Concepts and Terms

1. Storage of Unused Lids

2. Glass containers

Hot Treatment (TEC)

Cold treatment (TEF)

3. Fill

Filling cleaning

Floating product

Head space and product filling temperature

Table 1

Occluded air

Transportation of glass containers

4. Closed

Vacuum levels at the exit of the closing machine

Caps with button

Closing machine and line stops

Cap feeding systems

5.Closed Container Handling

6. Heat Treatment (Processed)

Pasteurization

Sterilization

7. .Drying of Packaging, Palletizing and Storage

Drying

Palatization Storage

APPENDIX A:EXTERNAL CORROSION OF THE COVERS

APPENDIX B : CLOSURE AND ADVANCE SECURITY MEASURE (TWIST OPEN COVERS

Recommended closing safety values (standard propeller mouth finishes)

Packaging with angle-flat thread

Closing safety in CX 43-48-TO-B (FD157 A and D), propeller thread version 43/48 mm TO

Cap Advance (Twist Open Lids)

Cover feed on CX 43-48-TO-B (FD157 A and D), 43/48 mm TO thread version

Combined measure of Advancement and Closing Security

APPENDIX C : PACKING LINES CONTROL PROCEDURES

Unit Conversion Table

These instructions cover the main points of observation in the use of Twist, Open, PT and PT Plus caps. Those will be applicable in all standard filling operations where the caps are going to be used in hot filling, cold filling, pasteurized and sterilized food products, covering the following points:

- Basic concepts and terms

- Storage of Unused Lids

- Glass containers

- Filling Operation

- Closed Operation

- Closed Packaging Management

- Thermal Processes

- Drying of Packaging, Palletization and Storage

The selection of the lid and the mouth finish of the glass container will be agreed with the Sales and SAC Departments of CROWN Closures Europe. Any modification in the model of use or in the formulation of the product in relation to the previously specified barnacle must be communicated to CROWN Closures Europe.

This information has been carefully collected from experience and from detailed tests. In case of conditions of use that deviate from these Instructions, the customer must contact CROWN Closures Europe and be convinced that the final product meets its requirements in all aspects.

All metal vacuum covers supplied by CROWN Closures Europe conform to the corresponding Legislation regarding materials and objects intended to come into contact with food. Upon request, CROWN Closures Europe will provide its current Certificate of Conformity with the Regulations regarding food contact.

Our Certificate of Conformity with the Regulations regarding total or specific migrations is based on the use of recognized simulants. The current levels of migration of materials from the lid to the food depend on the composition of the food product, the method used for the Processing of the package «packaged food- and the storage conditions that are carried out. It is the responsibility of the packer to ensure that migration levels are within the permitted limits as well as to carry out all the tests and controls that are necessary to establish such levels, since CROWN Closures Europe has no control over the actual conditions of use, composition, type of process or storage conditions of the final product

- Basic Concepts and Terms

This section includes part of the concepts included in these Instructions for Use and is only intended to explain the concept:

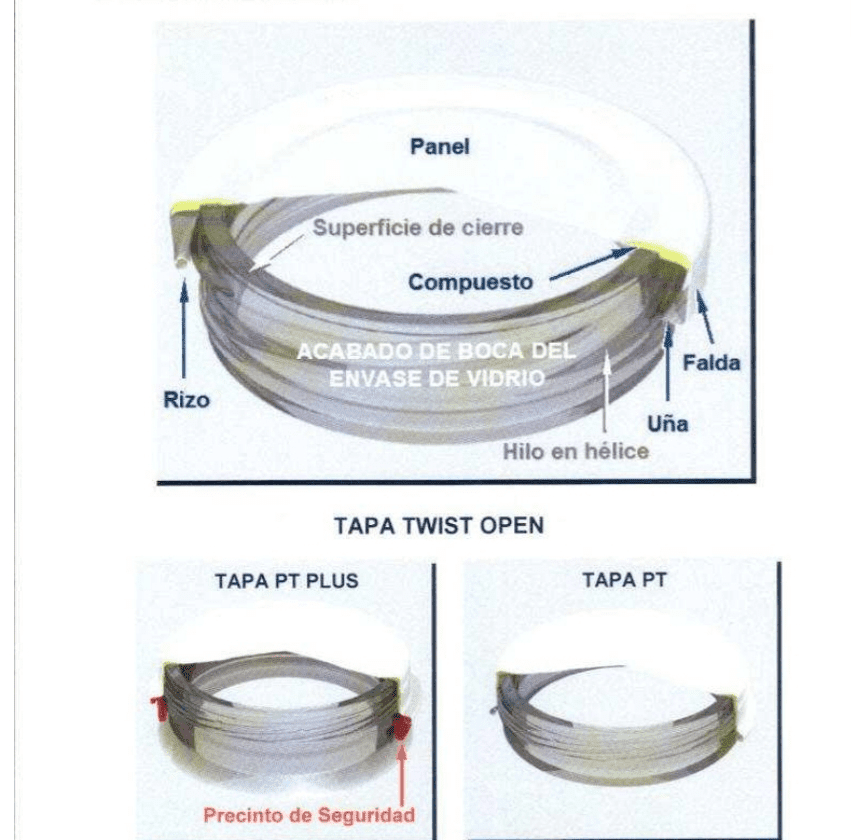

Lid application: action of placing the lid correctly in the container so that by turning clockwise (Twist Open) or pressure (PT and PT Plus) by means of a closing machine or manually a tightly sealed container is obtained, that is, a packaging

Button: raised circular portion in the center of the lid panel that functions as an indicator of the existence of vacuum inside the packaging.

Sealing compound: material applied in part of the inside of the lid and intended to be in contact with the closure surface of the container, creating a tight seal.

Deapplication of the lid: occurs when, in a package, the lid rotates in the direction of opening or counterclockwise without any external or manual action and that implies the loss of airtightness in a glass container, This phenomenon is also called “recoil” of the lid.

Packaging: glass container that, having been filled with foodstuff, has subsequently been sealed tightly using a Twist Open, PT or PT-Plus lid from CROWN Closures Europe.

Glass container: glass container or container intended to contain food product and with a mouth finish designed to apply Twist Open, PT or PT-Plus caps from CROWN Closures Europe.

Skirt of the lid: it is the lateral surface of the lid and surrounding the panel.

Lid panel: it is the central section of the upper circular part of a lid and which comprises the largest surface of it.

pa y que comprende la mayor superficie de la misma.

Processing: refers to the action of heat treating a packaging.

Process: heat treatment to which a packaging is subjected.

PT (Press & Twist): term that means Press (Press on) to apply the lid to the container and Turn (Twist off) to open the packaging.

PT Plus: is the PT cover to which an inviolability safety plastic ring is added (opening evidence)

Cover recoil: see cover disengagement.

Curl: is the winding of a portion of the falca at its open end. Protects the cutting edge and gives resistance to the lid.

Closing surface: upper surface of the mouth of the container that remains in contact with the sealing compound of the lid once applied, thus creating a tight seal.

Cap applied: result of the application of the lid.

Badly applied lid: lid that, for different reasons, is not placed correctly in the mouth finish of the glass container causing a non-hermetic closure and poor quality packaging.

TO (Twist Open): term that means Turn (Twist) to Open (Open) the container.

Nail: part of the curl specially shaped to be located at the bottom of the thread of the mouth finish of the glass container making the lid fixed to it.

Vacuum: lower than atmospheric pressure measured inside a closed container.

- STORAGE OF UNUSED COVERS.

Unused lids can be stored up to a maximum of two (2) pallets in height, always taking the utmost care. Pallets should be stacked vertically, without tilting and in a clean and dry environment, free of insects or pests. Damaged or wet boxes must be removed from the stack because they can cause the pallet to collapse and cause excessive loads on individual boxes, causing deformed or dented covers that will be out of use. Special care is required with PT Plus type caps to prevent damage to the plastic safety ring and its small plastic bridges that will result in a poor quality cap application.

Under any circumstances, contamination of the boxes and those partially used must be sealed again before storage.

PT Plus caps must not be used directly if they come from a cold storage area; In this case, the covers must be moved inside 24 hours before use to ensure that the plastic ring reaches room temperature (above 20 ° C).

The storage area should not experience extreme temperature and humidity values (that is, it must be 5 to 30 ° C and below 70% relative humidity) A stock rotation system (stock rotation) must be followed to ensure that the covers are used according to their manufacturing date (that is, the covers with the oldest manufacturing date are used first).

- GLASS CONTAINERS

The specification (design) of the glass container must be such that it prevents direct contact between adjacent container lids (contact between lids). Normally this is achieved by making the minimum external dimension of the glass container greater than the maximum external diameter of The lid use.

An error in the above will make closed containers sensitive to impact damage during handling and transport and will increase the risk of vacuum losses as well as possible deterioration due to leaks and product losses.

The specification of the capacity of the glass container is an important factor for the correct filling and subsequent processing of the packaged product. The correct limit capacity (or overflow capacity) of the glass container is essential for all operations involving a thermal process at a temperature higher than the filling temperature. An error in the specification of the correct capacity of the container will lead to difficulties in achieving the declared volume or weight of the product and will cause a risk that the closure (sealing) of the packaging will move during processing (recoil or unapplication of the lid) .

In order to achieve the correct head space volume at the time of filling, as specified in Table 1, it is important that the glass container specification take into account the following:

- Thermal expansion and, therefore, the volume of the product at the filling temperature.

- Variations in the filler and normal overfill to reach the declared volume / weight.

- Variations in the capacity of the batch of glass containers during the manufacturing process.

It is known that the treatments or coatings applied by the manufacturer to glass containers influence the behavior of the lid and must be kept within the agreed specifications. Due to the wide variety of coating materials and application methods in use it is not possible to establish detailed specifications in this regard but CROWN Closures Europe recommends :

Hot Treatment (TEC)

Excessive levels of hot treatment are proven cause of high opening pairs; They can also lead to problems with cap application and promote oxidation of the nails. CROWN Closures Europe specifies values below 20 CTU in the mouth of TO containers and below 10 CTU in the mouth of PT containers.

Cold treatment (TEF)

Cold coatings «cold treatments- are wax-like materials applied to glass containers after annealing to provide them with proper handling behavior in the packaging line.

Excessive levels of cold treatment on the body of the glass container can cause difficulties in the application of the lid due to poor control of the container as it passes through the closing machine. Normally, the TEF levels on the glass container body are well controlled by the manufacturer by measuring the sliding angle, although these specifications have to be agreed and maintained.

The cold treatment present in the mouth finish can cause problems in the behavior of the lid. An excess of TEF in the lower part of the threads of the mouth of the container can lead to a recoil (de-application) of the lid during the thermal process, causing a low safety of closure and a integrity of the final packaging of poor quality. Under certain circumstances the presence of these materials on the closing surface of the mouth of the glass container can cause high pairs of

Opening. As a result, CROWN Closures Europe specifies that the materials applied in the TEF are to be applied only on the body of the containers by spraying between rows so that the mouth finish of the glass container is not contaminated.

- FILL

It is necessary to take care of all the points related to the filling operation to achieve the production of safe and healthy packaging; Below are examples of the different areas that require checking and control:

Filling cleaning

Cleaning conditions in filling are essential. In the use of lids, the closing surface along the upper edge of the glass container must be free of product contamination. These conditions are especially important when it comes to solid or fibrous products, as this can lead to loss of vacuum.A dirty filling, allowing contamination of the neck of the mouth finish of the glass container with product, can cause problems of high pairs of

Opening and has to be avoided.

Cleaning conditions in the filling are also necessary to avoid external contamination of the glass container that could result in insufficient control of the same when passing through the closing machine or in the presence of product residues trapped in the area of the curl of the top. This can also lead to mold development or insect infestation.

Dirty filling and the presence of product residues trapped in the curl area of the lid can lead to oxidation problems of the lid (particularly if aggressive or acidic ingredients are used).

Floating product

The product should not be allowed to float above the surface of the liquid inside the glass container (steering liquid). If this occurs it could lead to problems in the closing operation due to the interference of the product with the flow of steam of the closing machine and the reduction of the nominal volume of head space.

Rigid products such as vegetables, vegetables, etc. they must not protrude above the closing surface of the glass container; these can interfere with the correct collection of the lid and lead to improperly applied or unapplied caps. These products in direct contact with the cover already applied can lead to stains on the inside system of the lid and increase the risk of internal corrosion.

Head space and product filling temperature

The filling, closing and processing conditions recommended for all standard processes are detailed in Table 1 on the next page.

Filling conditions that are not within these recommended limits must be considered as non-standard and the advice of the CROWN Closures Europe Customer Assistance Service (SAC) must be sought.

The volume of head space and the filling temperature of the product have a significant influence on the pressure that is generated inside the closed container during pasteurization and sterilization. In general, the higher the head space or the filling temperature, the lower internal pressure is generated.

The head space volume values shown in Table 1 are a percentage of the limit capacity of the container at the time of filling (that is, when the product is hot).

Tabla 1

|

Tratamiento Térmico (Proceso) |

Tipo de tapa |

Mínimo volumen de espacio de cabeza |

Mínima de Tº de cerrado |

Mínimo nivel de vacio (a salida de cerradora) |

Máxima Tº de proceso |

| Llenado en caliente y enfriamiento |

Todas |

5% |

85°C |

20KPa (15cmHg) |

85°C |

| Llenado en frio y pasteurizado |

Solo TO |

9% |

20°C |

50KPa (37cmHg) |

85°C |

| Llenado en caliente y pasteurizado |

TO |

6% |

65°C |

35kPa (26cmHg) |

90°C |

| Llenado en caliente y pasteurizado |

PT |

8% |

80°C |

28kPa (21cmHg) |

90°C |

| Esterilización con (contrapresión) |

Todas PT TO (solo hilo en hélice > Φ 48 mm) |

6% |

70°C |

40KPa (30cmHg) |

121°C |

Note:

The term Closed Temperature is used in Table 1 to represent the temperature of the product inside the container at the exit of the closing machine and not the temperature of the product in the container or container of the filler.

The list of closing conditions for Pasteurization refers to processes in a tunnel or open bath at atmospheric pressure, that is, without applying back pressure.

Occluded air:

Air occluded inside the product must be avoided. In some products such as fruits and vegetables, this can be achieved by letting them stand before filling; while for other products, such as solid foods, it may be necessary to use vacuum filling techniques.

Occluded air can lead to lower vacuum levels than expected resulting in the false ejection of packages because the safety button is up. For packages that are to be fully processed, an excessive value of the internal pressure can be generated during processing resulting in failures by breathing of the lid.

Transportation of glass containers

The transfer of glass containers from the exit of the filling machine to the inlet conveyor of the closing machine has to be designed to generate a constant space between containers (packaging passage). An error in this may cause a variable cap application (closing security). Badly applied covers (fingerprints, inclined caps or entrapment of the plastic ring of PT Plus caps) and unsealed containers.

For high speed applications we recommend our clients to consult the SAC organization of CROWN Closures Europe for detailed advice.

- CLOSED

The correct application of the cover must be checked at the beginning of production (initial start-up) and repeated every time the cover, packaging or the closing machine settings are changed. The measurement methods for covers of type TO are shown in Appendix B with instructions for the continuous monitoring of all types of covers in Appendix C.

For PT type lids it is important that the cap is fully applied and shown horizontally in reference to the closing surface of the glass container at the exit of the closing machine. To avoid poor opening behavior, the inviolability ring of the PT Plus lids must be placed correctly under the step of dimension B of the glass container without visible stretching of the small plastic joints or bridges.

Levels of vacuum exit of the closing machine

The vacuum levels at the exit of the closing machine depend mainly on the temperature of the product, the volume of head space and the speed of the line.

To ensure correct and constant adjustments of the steam control valves, vacuum measurements must be made before starting production and periodically during normal production.

If the products are filled in hot it is more correct to monitor the settings of the steam controls by measuring the vacuum in containers filled with cold water. This vacuum test with cold water will eliminate fluctuations in the vacuum levels obtained and that have their origin in differences in the temperature of the filler and in the volume of head space. The procedure is as follows.

Fill a glass container with cold water leaving a constant and known head space, for example 12 mm (this head space will reflect the normal filling level of the container to be used in real production) To minimize the possible occluded air, pass the container through the closing machine and discard the lid. Repeat the closing operation and measure the vacuum inside the closed container. This data must be recorded in the daily line control notebook.

The result obtained for the cold water vacuum test will vary greatly depending on the diameter of the glass container and the settings of the steam controls. When the maximum vacuum value is required (for example, for high temperature thermal processes) a typical value for the cold water vacuum test will be greater than 65 kPa (48.5 cmHg) for wide-mouth glass containers . In many cases the required vacuum will be much smaller, so the vacuum test with cold water will be performed only to establish constant adjustments for each production shift.

Normally vacuum values are achieved at the closing machine output above 40 kPa (30 cmHg) ensuring that a minimum vapor pressure of 550 kPa (5.5 bar or 80 PSI) reaches it. However, under certain conditions, lower vacuum levels can be used, well our recommended minimum vacuum levels are listed in Table 1.

Note: Additional information on the cold water vacuum test and the efficiency of the closing machine can be obtained from our CROWN Closures Europe Customer Service Department (SAC).

In caps with button

It is essential to ensure that the vacuum inside the packaging is maintained above the recommended levels to ensure that the button is lowered.

The actual minimum vacuum required for the correct operation of the button covers will vary according to the size of the button and the thermal process conditions in use. Button down values are generally valid to meet the requirements of our customers, who will discuss this with your local CROWN Closures Europe Sales Delegate.

The behavior of the button can be seriously affected by a strong pressure of the closing shoe on the closing machine. Using caps with button in 30/38 formats make sure that the pressure of the springs of the closing shoe and the adjustment of the jump of the same are kept in the minimum necessary for a correct application of the lid (See “Packaging of glass with flat wire ”in Appendix B).

If vacuum detectors are installed in the production line, the recommended vacuum value for the button to be lowered must be reached before this stage.

Closing machine and line stops

The containers must not remain inside the closing machine when the Production line stops whatever the reason may be. Some of the containers that remain inside may be subject to excessive heat or condensation of water near the area of the lid socket, so they must be removed when the line starts again.

An automatic steam cutting device must be used to interrupt the supply of the steam to the closing machine when the filling line stops. This reduces unnecessary waste of steam while avoiding excessive preheating of the covers in the area of the cover making that can cause problems with the application of covers and closing or sealing.

Cap feeding systems

The lid feeding system as a whole (independent mast feeder, hopper feeder incorporated into the seamer and lid transport ramps) must be cleaned regularly to avoid any risk of product contamination. The lid feeders (both types) have to be emptied to perform a thorough cleaning ensuring the complete elimination of any type of dust, particles or dirt that could be transported by the covers yet unused until the full container.The cleaning procedure should be detailed in the client’s Safety and Food Hygiene plan.

5. HANDLING OF CLOSED CONTAINERS

At all stages of the filling, closing and processing operations the containers must be handled with care to avoid abuses that could lead to vacuum losses, spills and deteriorated packaging. The following points are of particular importance during the handling of the containers.

The lateral guides of the transport lines, conveyors and accumulators must be adjusted to a height such that they support and contact the body and shoulder of the glass container; They should not come in contact with the skirt of the lid.

Conveyors have to be synchronized to maintain the space between containers to eliminate any sudden impact that could alter the integrity of the closure or seal. The containers filled at any point in the filling line must not be allowed to fall.

During the loading and unloading of the baskets of the autoclaves, care must be taken to eliminate abuse due to blows. During the transfer of the containers to and from the baskets of the autoclaves, the speed of this operation must be reduced to the minimum necessary. The pusher bars must be adjusted to avoid excessive pressure and the possibility of damaging the covers when they are descending or advancing.

The design of the baskets of the autoclaves and the machinery for their handling must ensure that there are no damages that have their origin in the mechanical handling of full baskets.

In vertical autoclaves it is important to ensure that the containers are not stacked up to one level per above the upper limit of the basket or, otherwise, damage to the covers may occur due to the pressure exerted by the basket (s) above.

Perforated plastic or rubber separators must be used to separate the layers of containers and these must be kept clean and in good condition to avoid damage to the lids.

Processed containers containing low acidity foods (pH> 4.5) should not be handled with the hands when they are still wet due to the existing risk of Microbiological contamination (Previous experiences in the processing of metal containers – cans for food products have shown a micro-filtration through the closure when wet cans are cooling. This procedure eliminates any possible risk of transfer of pathogenic elements from the skin of a person).

It is recommended that vacuum detectors be installed in the line after processing so that those packaged with low vacuum or without vacuum are removed. A regular examination of all the containers ejected by the vacuum detector should be carried out to establish the reasons for the failures and take the appropriate corrective actions.

6. THERMAL TREATMENT (PROCESSED)

Pasteurization

In pasteurization operations using a pasteurizing tunnel (without back pressure) it is possible to exceed the recommended process temperature in Table 1 only if the difference between the pasteurization temperature (higher) and the product filling temperature (lower) is less than 10 ° CThis small temperature difference is essential for PT type caps.

In pasteurization operations using an autoclave (with counter pressure) it is possible to use a lower product filling temperature and a higher pasteurization temperature, but this can only be done after consulting with CROWN Closures Europe.

Sterilization

The points listed below are critical during sterilization:

Correct Back Pressure Conditions

The internal pressure generated inside the container during its processing is given by a Combination of filling and closing conditions and the process temperature. To ensure the integrity of the container through the thermal process and the beginning of the cooling phase, the external pressure on the containers inside the chamber (autoclave or continuous sterilizer) is maintained at a higher level than the internal pressure generated inside of the container This prevents the displacement of the cover (recoil) and alterations of the sealing compound along the closure surface (compound footprint) when it is in its softest state.

The pressure difference during the process maintenance phase (pressure value inside the autoclave minus the pressure value inside the container) must be between a minimum value of 30 kPa (0.3 bar) – for prevent the displacement of the lid- and a maximum value of 70 kPa (0.7 bar) -to avoid cutting compound-

The term “back pressure” is used to describe the total pressure recorded in the process chamber and is the sum of the pressure caused by the steam required to reach the process temperature and the pressure exerted by the forced compressed air. The maximum internal pressure generated inside the container during its processing can be calculated using the “CROWN Pressure Calculator”.

This tool can be found on the CROWN Closures Europe Extranet site; please

Contact your Sales Office if you need username and password details

For an established process temperature, any tendency towards lower vacuum values, lower product filling temperatures or small head spaces will lead to an increase in the internal pressure generated inside the containers and a greater danger of displacement of The lid during the process.

This is why it is very important to control these factors and establish a safety margin for minor deviations during production once the nominal value of the back pressure is established. To establish the necessary nominal back pressure, the following method is proposed:

12 random samples of closed containers are taken from the packaging line under conditions normal production and, the worst values found for the three previous parameters (that is, the lowest vacuum, the lowest product temperature and the lowest head space) are the ones that will be used to calculate the pressure in The inside of the container. Having thus established the maximum internal pressure generated, add to this figure 30 kPa (0.3 bar) and use the final result as a nominal back pressure to apply during the process and in the initial cooling phase.

Limitations of Back Pressure

The maximum nominal back pressure to which the covers can be subjected is 200 kPa (2.00 bar) for Twist covers and 225 kPa (2.25 bar) for PT covers. The maximum acceptable depression fluctuation around the nominal back pressure will be ± 20 kPa (± 0.2 bar).

If the calculations show that the required nominal back pressure is greater than the maximum allowable back pressure, the filling or packaging conditions must be modified [The alternatives are: increase the initial vacuum level, increase the filling temperature, increase the volume of space head or reduce the process temperature to use].

Under controlled conditions, the maximum nominal back pressure can be exceeded but only after consultation and written agreement with CROWN Closures Europe.

It has been found that the highest internal pressure recorded during the processing of the container is normally reached at the beginning of the autoclave cooling phase or cycle, so special care must be taken at this stage. Excessive back pressure can cause the sealing compound to be cut along the closing surface or it may interfere with the proper functioning of the safety button and must be avoided.

It is important to apply the back pressure as soon as the process chamber has been closed and steam / water begins to enter. The back pressure must be maintained at its nominal value during processing and during the initial cooling phase, when the temperature of the product inside it is still high.

The nominal back pressure must be maintained during the first 10 minutes of the cooling phase or cycle and then reduce it to 50-100 kPa (0.5-1.0 bar) to complete the cooling phase or cycle.

For more advanced control systems, the pressure reduction ratio can be modified to meet the cooling ratio of the containers. The European SAC Department of CROWN Closures Europe can provide guidance in this regard based on the heat penetration values supplied by the client.

Limitations in Process Temperature

The maximum nominal process temperature is 121 ° C for standard sterilization processes. Temperature fluctuations during the process must be maintained within the range of – 1/2 ° C to + 2 ° C.

Only the process temperature of 121 ° C may be exceeded under controlled conditions subject to consultation and written agreement with CROWN Closures Europe.

Use of Rotating Autoclaves: Special Conditions

When using rotary autoclaves for thermal processes, it is necessary to prevent the movement of the containers inside the autoclave baskets using an external fixing mechanism. There are several types of fixing mechanisms and the most common options are:

- Manual application of a mechanical load by means of an individual plate or plate that acts on all the baskets inside the autoclave.

- Application of a pneumatic load by means of a fixing plate for each basket of the autoclave.

The objective of any of the above fixing mechanisms is to prevent the movement of the containers during processing using the minimum amount of force applied. This minimum force must be determined by tests with each autoclave equipment and the containers in use.

To avoid problems of damage to the compound and the external decoration of the lid, the following instructions apply:

a) All packages must be organized by layers or levels to coincide in the autoclave basket (fill it completely without leaving any gaps) and be stacked on top of each other to form columns of multi-level containers (column stacking).

b) A uniformly flat, soft and perforated rubber or silicone separator must be placed horizontally on the plane formed by the panel of the covers on each layer or level.

c) Next, a rigid and perforated polypropylene separator must be placed between the previous rubber separator and the bases of the next layer containers.

d) These separators must be in good condition, free of dirt and deposits of flakes or rust from the autoclave.

These separators are a very important help to avoid the movement of the containers, distribute the applied load and attenuate the variation in height of the containers. There should be a procedure to clean and inspect these separators regularly and replace them when necessary.

e) If metal separators are used at the top of the autoclave baskets, they must be designed to distribute the load evenly across the entire surface of all the lids. It is very important that any perforated interior separator has small gaps (for example, less than half the diameter of the lid) since an oversight in this can result in the entire load of the fixing mechanism being applied on the axis of some covers . A rigid perforated polypropylene separator must be placed under the metal separator to fully distribute the applied load. The metal separator must be uniformly flat, rigid and free of surface projections such as rivets or welding debris.

f) Whenever an iron fixing system is used that applies a load on several

baskets, it is essential that all be loaded in exactly the same way and at the same height.

g) If the fixing load is applied manually, a torque indicator must be used to ensure that the applied load is constant for all operators.

h) When a pneumatic fixing system is used, a mechanical seal should be used to avoid excessive work (travel) of the cylinders during processing.

i) With all systems it is important that the base of the baskets and the upper plates be show uniformly flat, rigid and free of dents. An inspection and repair or replacement procedure for damaged baskets must be implemented.

The correct and uniform distribution of the force of the fixing system around the complete circumference formed by all the packages is the most important factor to obtain success in the operations of rotary autoclaves.

Insufficient fixation at any point of the basket will allow the movement of the containers during the process and will cause clearly visible damage to the outer system of the lids (coating and lithography) There is also a risk of alterations of the compound throughout the process. closing surface (compound footprint) and recoil (de-application) of the covers during processing causing poor quality closing security and, consequently, deteriorated packaging due to product leaks or leaks.

Excessive fixation at any point of the basket will cause the compound to be cut (softer due to the process temperature) along the closing surface causing less resistance to abuses and deteriorated packaging due to leaks.

The rotation speed also has an influence on the movement of the containers; experience indicates that a rotation speed of up to 12 rpm is acceptable, although higher speeds would always be possible subject to satisfactory tests and agreement of the results with CROWN Closures Europe.

Application Considerations to All Processes

The following points apply to all processing operations and must be observed to obtain the best closing behavior.

The quality of the water used during processing is an important factor in the behavior of the closing. To avoid problems of corrosion, damage or marks on the outer cover of the lid, please refer to Appendix A.

Make sure that the highest layer of the containers in the autoclave is at least 15 cm below the process water level and that there is a head space between the water and the top of the autoclave chamber of at least 15 cm . This will minimize pressure fluctuations during processing and cooling.

To reduce the risk of thermal shock in the containers and a deterioration of the closure thereof, the temperature of the water introduced into the process chamber must not be significantly higher than the product’s filling temperature.

The temperature of the product inside the container at the end of the thermal process, that is, at the moment when the cooled containers leave the process chamber, must be lower than the initial product filling temperature (Note that containers should not be overcooled, as detailed in Appendix A. page 21).

Some products (for example, with tomato base) can cause stains on the external decoration of the lids during processing and it is very important that clean process water be used immediately after detecting broken, capless or evidence of spillage of This type of products.

7. DRYING OF PACKAGING, PALETIZED AND STORAGE.

Dryind

All metal lids intended for vacuum closure are manufactured from a flat metal sheet with a bare metal cutting edge with the risk of rusting. During the manufacturing process, care is taken to protect this cutting edge inside the lid curl, but the moisture trapped during filling and processing will pose an unpleasant risk of oxidation.

It is essential to thoroughly and thoroughly dry the lid containers after processing to remove all water, including water trapped between the inside of the skirt or side of the lid and the neck of the mouth finish of the glass container. This drying must take place before final packaging and subsequent storage, particularly where a plastic safety seal system (or opening evidence) is used on the lid and neck of the container.

Failure to dry the area between the inside of the skirt of the lid and the neck of the mouth finish of the glass container can create isolated particles of rust that contaminate the product when opening the container.

CROWN Closures Europe cannot be held liable for claims due to improper drying.

This topic is covered in detail in Appendix A “External Corrosion of Lids”.

Palletizing Storage

The containers can be palletized for storage in retractable plastic, in cardboard boxes or loose. When working with critical products, such as baby food, it is normal to subject all stockpiles to a 2 to 3 week incubation period to allow routine microbiological controls.

It is essential to take special care during the initial phase of handling the containers after the process to avoid altering the closures while the sealing compound cools and hardens completely. During the first 24 hours after the process or until all the containers are completely cold, any abuse on the lid should be avoided, for example, excessive top loading by pallet stacking.

When the containers are stored loose on the pallets, layers of corrugated fibrous cardboard separators must be used between the layers of containers. Prior to labeling, grouping in shrink wrap or cardboard boxes, the containers should be subjected to a repeated vacuum detection to eliminate those that may have suffered a slow loss of vacuum due, for example, to small cracks ( micro-fissures) on the closing surface of the glass container mouth finish.

When packaging is packaged in shrink wrap trays rather than in cardboard boxes for distribution, micro-corrugated cardboard must be used for the trays as it provides the best resistance to the lids against abuse due to excessive stacking weight. If the containers are packed in shrink wrap without trays, corrugated fibrous cardboard dividers must be placed between each stacking layer.

To minimize possible problems of corrosion or external oxidation in the covers, the paper or cardboard used must be low in chlorides (not more than 0.05% NaCI) and sulfates (not more than 0.15% Na₂SO₄.).

Used pallets must be in good condition. In stacking operations, pallets must be placed slowly and carefully to minimize uneven load distribution on lower pallets. Wooden boards of 12 to 15 mm thick must be placed between each stacked pallet to avoid uneven load distribution caused by the non-use of double-sided pallets. The upper surface of the pallets used must be solid in at least 80% of the total surface (that is, up to 20% of hollow space) with a maximum distance between boards of 25 mm.

To avoid problems of loss of vacuum during stacking and storage, the minimum warehouse temperature must be between 10 and 15 ° C.

Provided that the recommendations set forth above are followed, up to a maximum of three (3) characteristic pallet heights of 1000 kg / pallet can be stacked. It is not allowed to stack at more than three (3) heights.

Appendix A: EXTERNAL CORROSION OF THE COVERS

Failure to follow the instructions below and efficient drying of the lids before the packages are packaged, will most likely promote oxidation of the lids or the appearance of watermarks during storage or immediately after processing.

(a) Both the lid and the body of the container must be completely dried before palletizing, shrink wrap or application of the security plastic seal.

When used, the drawers or baskets containing the containers must be tipped over or tilted to allow excess water remaining in the lids to be removed (drained).

The use of high speed propelled air dryers is essential but in addition the containers must remain no less than two minutes in the transport lines before they reach the plastic shrink wrapping stations, cartoning or applying the plastic safety seal to the top. This will help moisture evaporate from the covers.

The design and position of the air blowers (nozzles) of the drying units are critical to completely dry the inner side of the skirt of the lid. To remove retained water between the inside of the skirt of the lid and the neck of the mouth finish of the container, some blowers of the drying system have to be oriented at an angle and upwards under the level of the lid curl in what height refers. Making the containers rotate on themselves as they pass through the air blowers will greatly increase their drying capacity.

When batch processing takes place, the containers must not be allowed to dry in the baskets; At the end of each process, all the packages have to go through the final drying and packaging operations. If a plastic safety seal is used (on the lid and neck of the container), it must be designed with air vents or perforations to aid in the drying process.

(b) Over-cooling of containers

The residual heat of the processed packages combined with the residence time of these in the conveyors before final packaging is very beneficial for drying them. Subject to product quality or microbiological issues, it is considered unnecessary and undesirable to overcool containers less than 43 ° C.

However, customers who package products that are known are aggressive and that generate a risk of internal corrosion of the lid must completely cool all packages to a temperature (reached in the same center of the container) below 40 ° C (for example, pickled vegetables or pickled vegetables, etc.).

(c) Conditions of water used in processing and cooling

The corrosive effect of moisture and air can be minimized by using appropriate additives in the water.

These additives must be selected in such a way that they do not reduce the bactericidal treatment used, the chlorination of the water or the external coating of the lids.

To minimize corrosion, watermarks and reduce rust scales, a type of process or cooling water must be:

Water softened on the basis of the exchange process, where calcium and magnesium ions are replaced by sodium ions, can lead to highly corrosive water whose alkalinity increases significantly at sterilization temperatures. This type of water has the ability to cause damage to the outer system of the covers.

Packers whose water supply, autoclave systems and operating practices require the use of softened water should use an adequate water treatment system to minimize the risk of unwanted effects of softened water based on the aforementioned exchange process .

Excessive chlorination of the cooling water must be avoided. In general, corrosion problems are apparently not due to this if cooling water with a total Chlorine content of less than 10 ppm is used. Chlorination of water at levels above 20 ppm is not acceptable.

Water treatment systems designed to take into account the quality of untreated local water are available from specialized companies such as: Betz Dearborn, Nalco, Buckman, Drew Ameroid.

(d) Improper maintenance of heat treatment equipment

Pasteurizers, autoclaves, baskets or rusty water pipes can result in the oxidation being transferred to the lids during the heat treatment and, thereby, promoting the oxidation of the lids themselves. This situation must be avoided with an appropriate treatment of the water used during pasteurization, processing and cooling. When the water is recirculated, it is advisable to change it at least once a week to introduce a filter into the system.

(e) Bad storage or storage conditions

Final packaging and unused lids must be stored in a cold and dry warehouse. The warehouse must always be dry to avoid oxidation and, in addition to the need to avoid rain and steam in this area, it is also necessary to avoid condensation of atmospheric (ambient) moisture on the covers.

(f) Excessive hot treatment at the mouth finish of the Glass container.

The levels of coating or hot treatment (TEC) vary according to the diameter and the finish of the mouth and the specifications in detail must be agreed with the manufacturer of the glass containers. CROWN Closures Europe requires values below 20 CTU at the end of TO container mouths and below 10 CTU at the end of PT container mouth.

Excessive levels of TEC can contribute to the corrosion of the nails of the caps and cause high opening pairs

(g) Lack of cleanliness in filling

Dirty filling that results in the presence of product residues trapped in the area of the lid curl can lead to oxidation problems (particularly when aggressive or acidic ingredients are used).

(h) Incorrect or improper treatment of boiler water

Regular maintenance of the boiler, corrosion inhibitors or chemical treatments used in the feed water must be carried out in a non-corrosive environment that does not damage either the lid or its exterior coatings or systems.

CROWN Closures Europe cannot be held liable for claims due to corrosion due to failure to comply with these instructions.

Appendix B: CLOSURE AND ADVANCE SECURITY MEASUREMENT (TWIST OPEN COVERS)

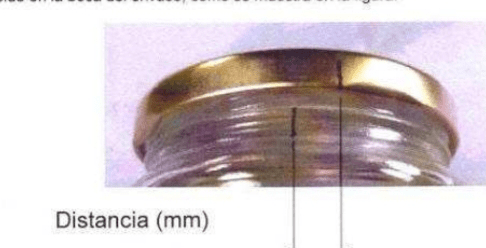

The closure safety measurement is a direct indication of the integrity of the closure and the resistance to abuse of the TO covers. The safety of closing is the distance in millimeter between the position of the lid as it is applied and the one it occupies after its opening and a new closed back (re-application), this time with a simple light pressure of the fingers without tightening .

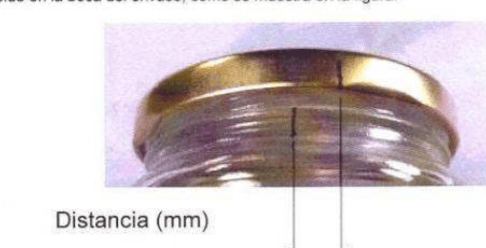

The method used to measure the safety of closure is shown in the following images:

- Mark the skirt of the lid and the neck of the glass container with a common stroke.

Open the lid until the vacuum is lost and close again with light finger pressure.

- Measure it distance between the two marks

Distance (mm)

The safety of closure is positive when the lid mark is to the right of the container mark. Otherwise, the safety of closure is negative and the integrity of the package may be of poor quality.

Closing safety checks should be carried out and recorded at the beginning of each work shift and then at regular intervals of time whose frequency will be dictated by practical considerations such as line speed, etc.

The safety of closure must be checked every time any of the components of the packaging (item of packages or lids) changes, when the product to be changed is changed or new adjustments are made in the closing machine. The control will be carried out on at least three consecutive containers at the exit of the closing machine.

To ensure the correct integrity of the closure after cooling, the safety of closure must be rechecked at the end of the process as well as at the exit of the closing machine and with the same frequency.

Recommended closing safety values (standard propeller mouth finishes)

|

TAPAS NO ESTERILIZABLES |

TAPAS ESTERILIZABLES |

||

|

TAPAS CON 4 UÑAS (53 a 70 mm TO) |

|||

|

SALIDA DE CERRADORA |

5-8 mm |

SALIDA DE CERRADORA |

5-9 mm |

|

DESPUÉS DE ENFRIADO |

3-8mm |

DESPUÉS DE ENFRIADO |

1-5mm |

|

TAPAS CON 6 y 8 UÑAS (77 a 110 mm TO) |

|||

|

SALIDA DE CERRADORA |

3-6 mm |

SALIDA DE CERRADORA |

3-8mm |

|

DESPUÉSDE ENFRIADO |

2-5 mm |

DESPUÉS DE ENFRIADO |

0-3 mm |

Packaging with angle-flat thread

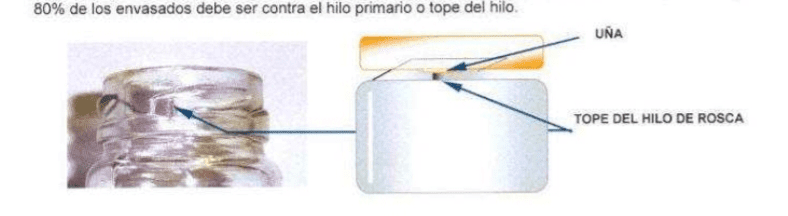

For the best cover application in containers with a flat angle, the position of the nail in at least 80% of the packages must be against the primary thread or top of the thread.

For the remaining 20% of the containers, it is critical that the entire nail is well positioned on the flat or horizontal part of the thread to ensure that the cap has been sufficiently applied.

The dimensional characteristics of each item of lids, of each item of glass containers or of the closing conditions may require different adjustments of the closing machine so that the lids are properly applied.

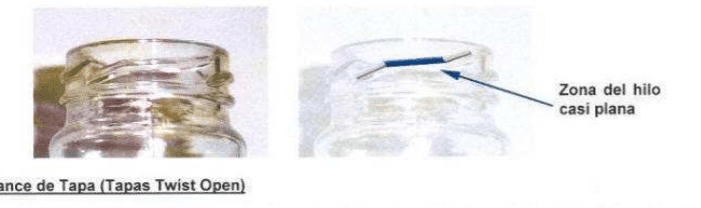

CX safety lock 43-48-TO-B (FD157 AD) propeller thread version 43/48 mm TO

This small thread in diametral helix has three distinct sections with an almost horizontal central portion (little pronounced helix angle) The nail of the cap should come to rest on or towards the end of this central part of the almost flat thread. The closing safety is measured in the usual way and the values must always be above 6 mm.

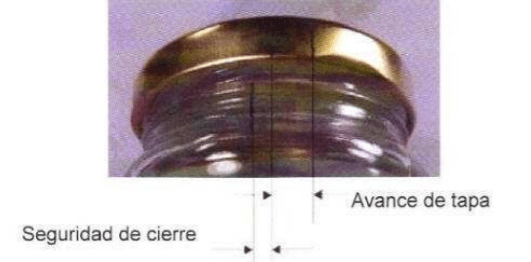

Advance (Twist Open Lids)

The measure of the cover advance is an indication of the degree of application of covers of the TO type. It is the distance in millimeters between the leading edge of the nail (beginning of the nail) and the line of division of the mold in the mouth of the container, as shown in the figure:

The procedure to measure progress is as follows:

- Locate and mark one of the lines of division of the mold that passes through one of the threads in the mouth of the glass container (take into account that the division of the mold in the mouth of the container may not coincide with that of the body of the same) .

- Locate and mark the leading edge of the nail that is placed in this thread.

- Measure the distance between the two marks to obtain the advance of the lid in millimeters.

The advance is positive when the nail of the lid is to the right of the brand of the mold of manufacture of the container (as the previous image shows). Otherwise, it is said that this measure is negative and that the cap is “over-applied.”

The target feed is 9 mm (+9 mm)

Notes:

- A wide total tolerance appears for the measurement of the cover advance as a result of the variations from starting to starting in the thickness of the compound, in the height of the nail and the height of the thread in its central (almost flat) section of the helix angle. The variation in the feed should be much smaller for an individual glass cover item (for example, ± 3 mm).

- The measure of the cover advance is a simple indication of the degree of application of the cover and has to be considered as secondary compared to the measure of closing security.

- The lid advance will not change as a result of a thermal process, and if it changes is an indication that there has been an unapplication of the lid through the threads of the container.

- For expert line operators it is possible to make additional visual inspections of the lid advance frequent intervals without marking or opening the container.

Cover feed on CX 43-48-TO-B (FD157 A and D), 43/48 mm TO thread version

This small diametral helix thread has three distinct sections with an almost horizontal central portion (little pronounced helix angle). The nail of the cap should come to rest on or towards the end of this central part of the low inclination thread. The cover feed is measured in the usual way and the values must be between 0 and 6 mm.

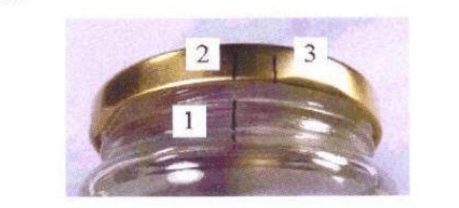

Combined measure of Advancement and Closing Security.

The cover advance is normally measured at the same time as the closing security by marking the cover in the three positions shown below. Position [1] represents the line of division of the mold on the neck of the glass container, [2] is the anterior mark extended on the lid and [3] is that of the leading edge (end) of the nail of the lid . Safety measures for closing and advancing the lid are measured in the usual way.

Open the container just until the vacuum has been lost and apply the lid again with slight finger pressure. The advance and closing security can be measured at the same time, as explained in the following image.

These measurements must be recorded in the line control table as an indication of the correct application of the cover.

Appendix C: PROCEDURES FOR CONTROLLING PACKAGING LINES

Checks of the cover application must be carried out at the beginning of the production process and then at each change of the cover item, packaging or closing machine settings.

(1) Record the details of the manufacturing item and the pallet numbers of the glass containers to be used to be filled with product as well as the date and time of use along with information of interest of the product.

(2) Record the details of the manufacturing item (lot and box number) of the covers used as well as the date and time of use.

Points (1) and (2) are essential to allow traceability of the components of the packaging in case of consumer complaints or packaging problems.

(3) You must check the vacuum test with cold water before beginning normal production. This will confirm the efficiency and consistency of the steam unit and the sealant settings.

(4) You should frequently perform a routine visual check of the closed containers (for example, every 15 minutes) to see that the application of the lid is correct, for example:

- Are all nails under the threads of the container?

- Are all caps correctly applied?

- Have the nails reached the top of the thread in containers with a flat angle?

- Is the plastic inviolability ring of the PT Plus lids correctly positioned on the wall B (dimension B) of the glass container?

(5) Every hour, check six containers at the outlet of the sealer, record on the production sheets:

a) Vacuum measurement

b) Measurement of the safety of closing and advance (only for covers of the Twist Open type).

c) Product temperature measurement.

d) Measurement of the level of product filling both by the depth of the head space and by product weight.

The line control sheet must reflect the acceptable limits for these parameters. This is especially important for sterilized containers where the filling and closing conditions to be achieved are essential for the correct thermal process.

(6) If the thermal process of the packaging has already taken place, the checks made at the exit of the closing machine will be repeated at the end of the packaging line. This will include a visual check of the fingerprint or print on the compound’s closing surface (correct print? Damaged print? Cut of compound?) And if necessary ensure that the safety button works properly.

(7) If measurements of the opening pairs are made, it is recommended that they be done after 24 hours, when the packaging is completely cooled and stabilized.

Unit Conversion Table

|

Factor de conversión |

In Hg |

Cm Hg |

kPa |

Mbar |

PSI |

Kg/cm2 |

|

In Hg |

1 |

2.54 |

3.3863882 |

33.863882 |

0.49115408 |

0.034531549 |

|

Cm Hg |

0.39370079 |

1 |

1.3332237 |

13.332237 |

0.19336775 |

0.013595098 |

|

kPa |

0.29529988 |

0.75006168 |

1 |

10 |

0.14503774 |

0.0010197162 |

|

Mbar |

0.029529988 |

0.075006168 |

0.1 |

1 |

0.014503774 |

0.0010197162 |

|

PSI |

2.036021 |

5.1714933 |

6.8947573 |

68.947573 |

1 |

0.070306958 |

|

Kg/cm2 |

28.959025 |

73.555924 |

98.0665 |

980.665 |

14.223343 |

1 |

Note:

The International System of Units (SI) recommends Pascal (Pa) as the derived unit to be used for pressure and mechanical stress.

0 Comments