SUMMARY

The calculation procedure is developed to determine the amount of compound to be applied on the wing of a fund. It depends on several factors, which can be synthesized into one, the size of the closure.

INTRODUCTION

The function to develop by the rubber applied in a bottom wing, is to wrap the hooks of the closure, covering any small cavity that can be formed between them. This eliminates the possibility of leaks in it.

To know in detail the characteristics of this material you can consult the work:

published on this Web previously.

There are two basic types of compounds or gums for closures, both are solutions of natural or synthetic rubbers in different liquid bases. Water based compound and solvent based compound. We will not enter into the particularities of them, already treated in other works. Now we will focus on how to calculate the amount of compound suitable to deposit on the wing of a fund to get a good closure.

FACTORS THAT DEFINE THE AMOUNT OF COMPOUND

The amount of compound applied, although controlled by weighing, since it is the fastest and most accurate procedure, should really be enough volume to perfectly fill the inside of the closure. Therefore, it is a question of defining volumes of dry extract deposited on the bottom wing. The magnitude of this volume is a function of several factors, all of them linked to the type of closure that is going to be used in the union of the bottom to the body of the container.

For this reason we must start by knowing this type of closure, and linked to it, the dimensions of the body flange and the bottom wing are automatically fixed. Each wing size corresponds to a certain volume per linear meter of compound. Defined the same, and known the length of the development of the wing, the volume per background is determined. From it, knowing its density and its percentage of solid content of the compound, it is easy to define the weight of liquid and dry compound required. Therefore the factors to be handled are:

– Nominal diameter of the bottom.

– Nominal width of the wing of said fund, depending on the closure used.

– Length of the development of said wing, that is to say its extension if it were placed in a straight line. We will designate it with the letter ” L “. It is simply a matter of calculating the length of a circle and it is expressed in mm.

– Volume of dry compound per linear meter ” V ” in mm3. It is a constant that is related to the width of the wing. Its value is indicated below.

– Gumming speed of gumming, that is to say revolutions per minute that the bottom must give at the moment of gumming to get a good application. The tangential velocity at the point of application must be constant for all the base sizes, therefore the rpm . they are reduced as the diameter of the same grows.

– Theoretical weight of appropriate dry compound, ie after the aqueous phase is removed therein. We designate it by the letter ” p “, and it is obtained by means of the formula:

p = V x L x d /1000

” d ” being the specific weight of the dry compound expressed in g / cm3. It is a fact that facilitates the rubber manufacturer.

– Theoretical weight to be applied of compound in liquid state. It is obtained by the formula

P = 100 x p / E

” E ” being the% solids content of the compound in the liquid state.

– The operation of applying the compound is somewhat imprecise, since it depends on the size of the drop that is detached from the injection nozzle. For the same adjustment, said drop is susceptible to variations depending on the viscosity, application temperature, cleaning state of the nozzle, etc. Therefore, the tolerance to apply on the theoretical liquid weight is quite broad, usually + 10%.

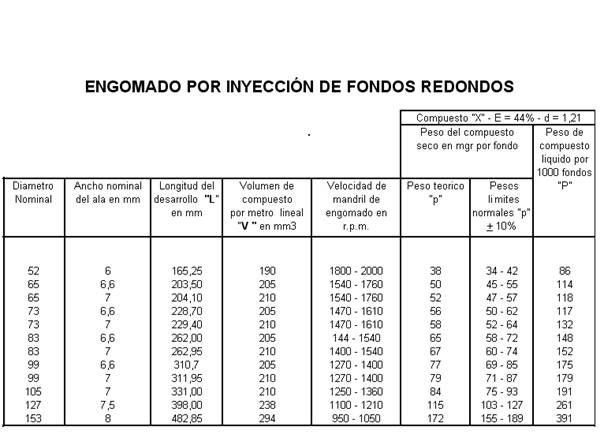

As a summary of all that has been said, we show below in the form of a table, the normal data of these factors ( L , V and rpm ) for different diameters and wing width. Also weights p, P and tolerances for an example of compound having a specific gravity of 1.21 and a solids percentage of 44%

0 Comments