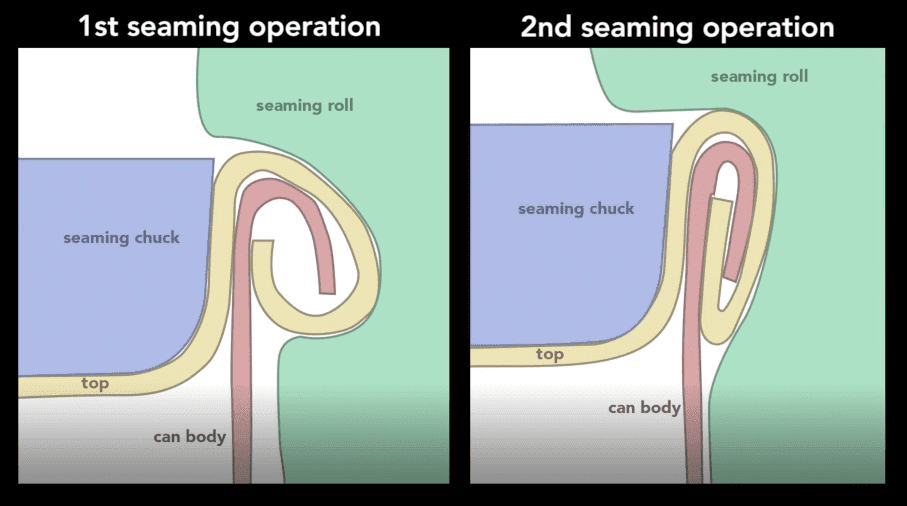

Verification of the closure of a 3-piece container, such as a tin can, involves inspection of the double seam that joins the body of the can to the lid and base. Here are some measures that can be used to verify closure:

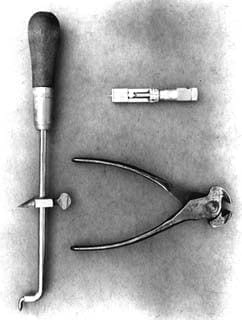

- Seam height: The distance between the top and bottom of the double seam. It should be measured with a caliper or micrometer to ensure that it is within the manufacturer’s recommended specifications.

- Seam thickness: It is the sum of the thickness of the can body and the thickness of the lid and base at the double seam. It should be measured with a micrometer and compared to recommended specifications.

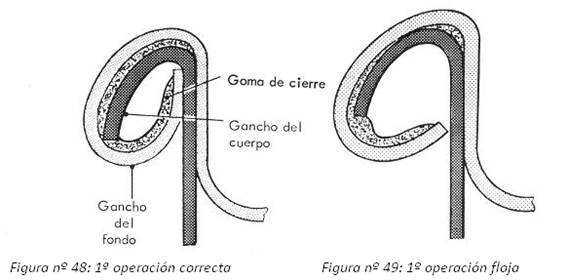

- Overlap: This is the length of the overlap between the can body and the lid and base at the double seam. It should be measured with a caliper or micrometer and ensure that it is within the recommended specifications.

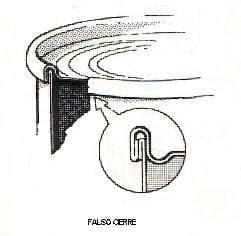

- Wrinkle: A small wrinkle in the double seam that may affect the integrity of the closure. It should be visually inspected and ensure that there are no excessive wrinkles or seam malformations.

- Composite gasket: It is the sealing material used in the double seam to guarantee a hermetic seal. It should be visually inspected to ensure that it is properly applied and that there are no leaks.

In addition to these measures, it is important to perform tightness and pressure tests to ensure the integrity of the seal and the quality of the packaged product. The manufacturer’s recommendations should also be followed and records of inspections and corrective actions taken should be maintained.

0 Comments