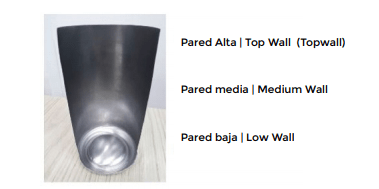

To reduce can top wall variations, it is essential to optimize the drawing and pressing process. The knowledge base provides some insights into this process:

- Adjust the reduction percentages: For taller cans, the wall thickens toward the top. You can reduce this wall thickening by adjusting the reduction percentages during the re-stretching process. The reduction percentage of the second redraw should be slightly lower than that of the first redraw.

- Wall ironing technique: You can use a special profile in the final mounting die and a reduced radial clearance to iron the wall during the mounting process. This technique can reduce the wall thickness to the original thickness or reduce the entire wall thickness, thus saving metal.

- Lubrication: During the wall ironing process, the can should be lubricated to reduce frictional heat. This helps ensure uniform and consistent wall thickness throughout the can body.

- Monitor the process: Regularly check equipment and process parameters to ensure that they are within specified tolerances. This will help maintain the desired wall thickness and reduce variations.

By following these steps and optimizing the drawing and pressing process, you can effectively reduce can top wall variations.