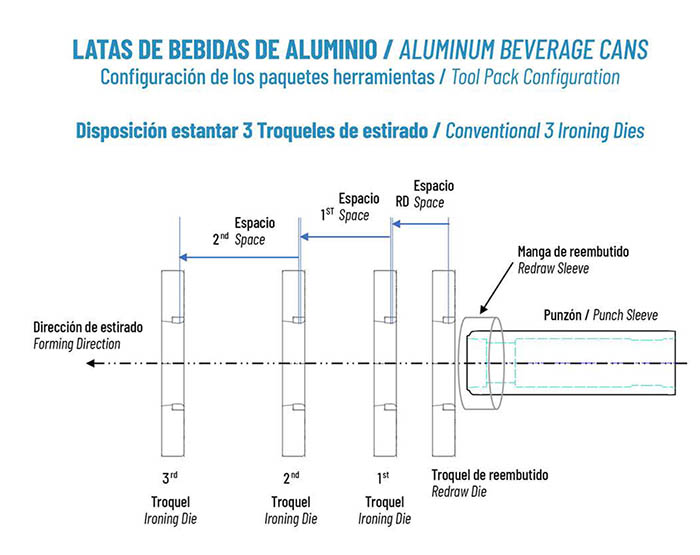

The tooling package used for body forming in a Bodymaker can have several types of configurations.

The most common configuration used in the industry is one Redraw Die and three 3 Ironing Dies, where each of these dies is housed in its own Die Holder.

In this type of configuration it is intended that the aluminum metal does not work in 2 ironing dies at the same time, thus avoiding a tensile test effect that could lead the material to its ultimate tensile stress (UTS) and in turn fracture the material.

The Redraw Die is required to perform a sizing process, where the thickening of the metal during the redrawing operation is controlled by the clearance between the punch and the Redraw Die, initiating the control of the Top Wall Thickness variation.

First and second drawing die

The 1st and 2nd Ironing Dies should be balanced in terms of metal reduction (24-25%), where the 1st Ironing Die could carry a higher metal reduction if required by the Forming Schedule.

Second drawing die

The 2nd Ironing Die is specified by the thickness of the Thick Wall and the existing process variation in this area of the can, compensating for the process variation in this die avoids the defect called Smile.

Third drawing die

The 3rd Ironing Die is specified by the thin wall thickness and by a metal reduction of no more than 40% to avoid reaching the ultimate tensile stress (UTS) of the material and thus avoiding Tear Offs.

DWI Training Guidelines

3rd Stretch die adjusts to the thickness of the middle wall.

2nd Stretch die is set by the thickness of the upper wall + process variation.

The 1st and 2nd draw die reductions must be balanced. The redrawing die should be of size ()t+%) metal for early control of wall thickness variation.

– Metal processing should not be allowed in two dies at the same time.

– The metal reduction of the 3rd drawing die and the reduction of the cup diameter have critical limitations.

A well-designed Forming Schedule in combination with the use of three ironing dies and its withdrawal die will lead to an excellent operating window in the forming area (Front End).

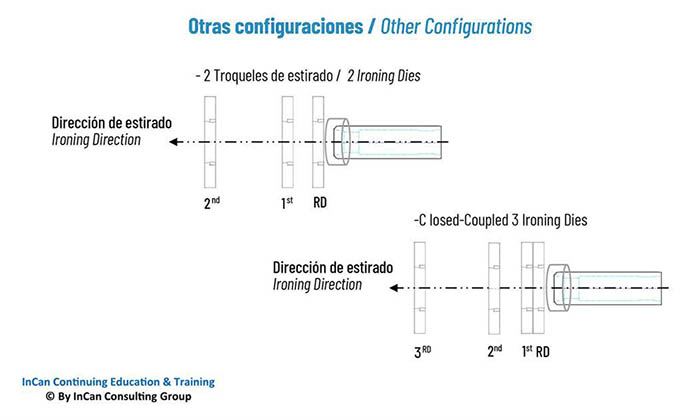

The other 2 most commonly used tooling package configurations are as follows:

– One Redraw Die and two Ironing Dies are used when there is not enough room in the tooling package for a 3rd die.

– A removal die coupled with the first ironing die (RD-1st Ironing – Closed Coupled) and two ironing dies (2 Ironing Dies), is used when there is not enough space between ironing dies.

0 Comments