Throughout the seventies, a series of events took place that substantially changed the metalworking industry. New technologies developed abroad were implemented in our country.

1º.-Thetraditional soldering of the seam of the body of the container – which was done from the beginning of its manufacture with an alloy more or less rich in tin – is replaced by an electrically soldered joint.

This makes it possible to eliminate lead contamination and improve its presentation.

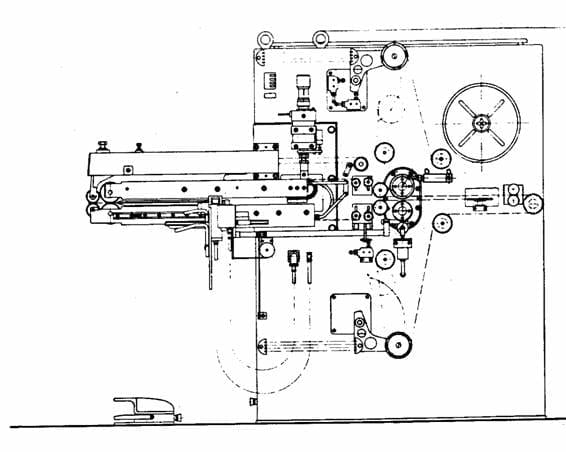

This modification makes it necessary to progressively change the front end of all the three-piece container production lines; this replacement requires a heavy investment because, as this is a new technology, second-hand machines are not easily found on the market, at least during the first few years.

The company developing this technique is the Swiss company Soudronic, which sells equipment to most Spanish manufacturers through Echazarra (Madrid), its delegate in Spain (13).

Its sales in this period skyrocketed because in addition to welding machines, it sold the complete range of machinery necessary for this industry.

Subsequently, other competitors appeared, such as Fael (also Swiss), but at no time did they represent serious competition for the former, and even ended up, as in the case of Fael, being absorbed by Soudronic.

Its invention and technology come from the USA.

In Spain they begin to be manufactured by Envases Carnaud (company that has been the continuator of Cía. Internacional de Envases) in its plant of Vigo.

Later, other companies such as Vivancos followed.

Slowly this type of closure gained ground until its use became generalized at the end of the century.

The investments necessary for its implementation are even greater than those of the previous point. 3º.-The consumption of canned drinks (colas, soft drinks and beers) soars, following in the footsteps of what happened previously in the USA.

This led to the introduction of a new two-piece container manufacturing technology – DWI “stuffing-stretching-ironing” – which quickly displaced three-piece containers from the market.

The construction of three-piece beverage containers was started by Envases Carnaud at its Valencia factory in 1967, but the market did not take off until a few years later (14).

The first ones were made to contain beer, specifically for the “EL Águila” brand.

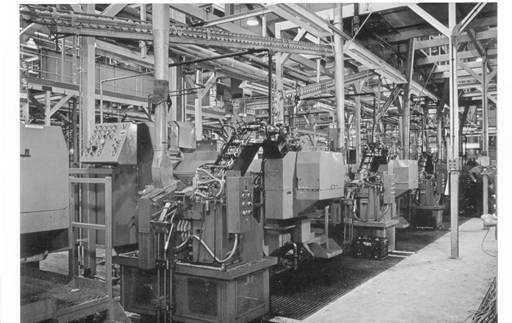

In 1981, two-piece containers began to be manufactured in a new plant of the same company in Agoncillo (La Rioja).

Soon another strong North American international company – Nacional Can Co- joins this sector by setting up a new plant in Valdemorillo (Madrid).

The complex technology and high production speeds make the investments even higher than for those mentioned above. 4º.-Thethree-piece containers of little height are progressively replaced by two-piece deep-drawn containers for similar reasons to those previously mentioned.

The means for their construction are relatively easy to obtain and several companies, especially in the fish sector, are putting them into practice.

(14) The beginning of the manufacture of three-piece beverage containers was due to the firm bet that Tomas Somohano – Technical Director of Envase Carnaud – made for its introduction in Spain. This engineer was of Asturian origin but as a child he emigrated to Mexico with his family. He was trained in the United States and held an important position in one of the plants that Continental Can owned in Mexico. When the aforementioned company signed an economic and technical agreement with Olmesa – now E. Carnaud – he came to Spain in 1961 to take charge of the technical management of the new company. He brought with him a wealth of knowledge and the experience of a market much more developed than the Spanish one. He was undoubtedly the most qualified technician that existed in this period in our metallurgical industry. After his arrival, he bet on introducing in Spain, one after the other, the products in vogue in North America and the most modern techniques for their manufacture. Thus from his hand came the “twist-off” lids, the palletization of containers, the easy-opening lids, the three-piece beverage containers, the DR tinplate, the two-piece containers (also for beverages and which later displaced the previous ones), the water-based varnishes and a very long etcetera that would make this footnote very long. He counted among his friends the greatest experts worldwide and he of course was one of them. He was known and respected in the best international forums. In a word, if one had to choose the person who did the most to raise the technological level of the metalworking industry in the second half of the 20th century in Spain, it would undoubtedly be Tomas Somohano.

(15) José Luis Marín, the main promoter of this new company had dedicated his life to printing on metal, initially as a technician at Metalcolor and later as director of Litarsa.

(16) Juan La Torre, grandson of the founder of the company, takes over the management of the company and modernizes the team and the catalogue of products, giving a strong impulse to the business.

(17) José Peñalver had been head of the mechanical workshop of Sánchez Rex where he acquired a good knowledge of equipment. When this company went bankrupt, he set up a workshop with another partner but soon became the sole owner. Initially he limited himself to small equipment following the Italian line, but later he made his own developments some of them with great success.

6.- END OF A CENTURY In the last years of this century we enter a situation where the fight for the market becomes very strong, since in the previous years the installed capacity has been increasing at a great pace, far above the needs of the canning industry. The century is coming to an end and with it the joy of investment. The market did not continue to grow at the same rate as in previous decades, competition became more intense and a period of difficulties threatened the sector. The causes are various: new types of packaging – plastic, “break”, glass… – are taking a share of the traditional can market; new consumer habits – imposed by the incorporation of women into the workplace – are changing the way food is preserved; the desire of canners to change the “old” image of the can, etc., etc., etc. There are companies that have recently invested heavily and their situation has become delicate. It is time to divest – the companies that can – before the situation becomes critical, starting this operation to make cash, especially the largest ones, for example Carnaud-Metal Box (CMB) – which has changed ownership for the umpteenth time – now called Crown Cork after being bought by the multinational of the same name, specialized in beverage containers and crown corks. Crown Cork already had two factories in Spain (Getafe and Bilbao) under the name of Metalinas dedicated to crown corks and aerosols, which determined, when reorganizing production, to close or sell some plants of the former CMB: the aerosol plant in Reus to U.S. Can. – The multinational specialized in this market segment, of North American origin, which was born from the fragmentation of Continental Can; those dedicated to oil cans – Linares and Camas – closes the first one selling its buildings and sells the second one to its immediate competitor Auximara – Epila (Zaragoza). (This last company had been created a few years before by a former manager of the first one). As the only market that follows a steady upward trend is the beverage can market, a second factory is set up in Seville. Previously, its competitor – Nacional Can – had done the same in Catalonia. At the beginning of the 21st century, it also closed the factory in Valencia and will probably make even more adjustments in order to seek an establishment adjusted to the future possibilities of the market.

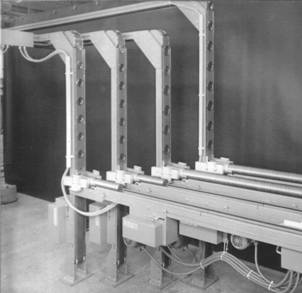

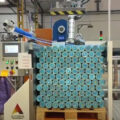

DWI container line – beverages Some other companies are following suit. The family that owns Mivisa sells the company with all its plants to two French investment fund companies The multinational Colep – Portuguese – buys Comercial de Envases (with two paint can factories in Calahorra and San Adrián). For others, unfortunately, the time has come to close. It is also time to reduce costs at all costs on different fronts: In raw materials by reducing metal thicknesses, in labor by reducing the workforce and relying on automation and robots, in management by hiring experts in the field… In short, the market is in a phase of “mature product” where the “know-how” can be obtained by anyone who has the money to pay for it and therefore there are no technological barriers but only economic ones. In these conditions only strong multinationals that can access large volumes of business have a chance of staying. Proof of this is the arrival in Galicia of Impress, a strong European multinational. Nevertheless, we believe that the can has a long life in Spain. The traditional fish and vegetable canning industries are still closely linked to it and new markets such as the beverage industry have taken it as their ideal vehicle. Our best wishes to her!

Alejandro Valderas

0 Comments