SUMMARY

In the traditional container of one kilogram in diameter 99, the pressure to reduce its cost has led over time, to change the profiles of the covers and bottoms, getting to improve their performance, at the same time as the material consumed was reduced.

BACKGROUND

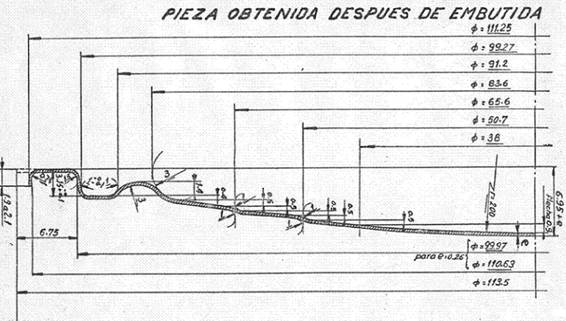

For a long time, it has been used – and still is used – for canning containers in diameter 99, especially in the traditional one kilogram boat, a very classic background, whose configuration is reflected in figure # 1. drawing shows the old diameter 100, common throughout Europe before standardizing the American format 99. The image reflects the piece obtained after stuffing and before curling. The dimensions are those of the manufacturing tool.

Figure nº 1

The profile of this fund includes, next to a peripheral bead and next to the wall of the tank, two concentric expansion panels, and a central expansion panel of slightly concave shape.

This fund, with more than 80 years of history, used throughout Europe, has given complete satisfaction as long as the thickness of tin used for it has been sufficiently strong (approximately 0.25 to 0.28 mm.). Its hardness was centered on the traditional T3 temple.

These high thicknesses began to be prohibitive several decades ago, since it was imposed to reduce the consumption of material when competition was accentuated in the sector. The decrease in costs prompted the search for new alternatives. Initially, the first step was to reduce the thickness, maintaining the same profile, and compensate for the decrease in pressure resistance resulting therefrom, with an increase in the tempering used, but it was soon detected that the behavior of the profile during the process in the Autoclave was not always satisfactory.

In fact, when some compact products were processed like spinach, the bottom profile, after warping outwards, due to the action of internal pressure, did not return properly to its initial shape even after cooling, despite the presence of a good a residual vacuum. The tin was permanently deformed and in the background there was a “raneo”, which caused serious problems in the clientele.

In addition, in some processes the bottom suddenly passed from a concave to a convex form and vice versa during the autoclave. In certain cases, especially when the filling temperature was not sufficient, the funds did not return to their initial profile without a manual operation, which was a serious drawback.

For these various reasons, packaging manufacturers were forced to use, for standard 99 (or 100) mm. Diameter, a sufficient thickness of tinplate to avoid permanent convalescence of the profile, although the thickness was usually too strong to avoid presence of “peaks” during a process under normal conditions.

In other words, it was possible to reduce the thickness of the funds diameter 99 (o100) between 0.01 to 0.03 mm without risk of spikes, but it was not possible to do so with the profile used.

NEW BACKGROUND

In the “seventies” of the last century appeared a generation of profiles of funds in which the thickness was reduced significantly and that solved the problems listed above.

After a series of attempts, with more or less existing, it evolved towards a new concept of profile, in which the central panels with steps disappeared, being replaced by asymmetric bends, all located almost in the same plane. This central area of the bottom is specially designed to offer great flexibility to the deformation, representing a great advantage.

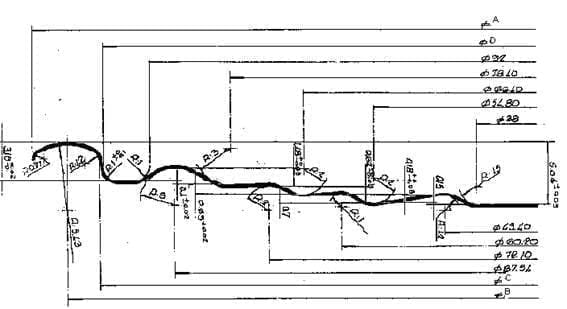

Figure 2 shows this profile, which is formed by a peripheral bead, which can be asymmetric or not, of a certain depth and a central panel with three asymmetrical low-height beading. In the drawing the piece is appreciated after embossing and before curling. The dimensions indicated are those of the die. The measurements bounded with capital letters are related to the standardized diameter of the container.

Figure nº 2

The application tests of this new fund showed the following effects:

– On the one hand, very gradual deformation under internal pressure of the container, during the process. The fund does not click suddenly as in the previously used funds.

– On the other hand, due to this gradual deformation, a progressive increase in the internal volume of the container is obtained when a gradual increase in temperature occurs.

– In addition, as soon as the package begins to cool when the temperature drops, and consequently the internal pressure decreases, there is a gradual return from the convex profile to the initial concave shape.

– After the process, the fund returns correctly to its initial profile if we use tinplate of greater hardness as it can be of temper T 4 or type DR. The result is the same if it is used as TFS material.

– The results allowed a significant reduction of the nominal thickness of at least 0.02 mm. In some cases greater.

This new generation of profiles was imposed little by by, starting with France, the country where it was designed. Today its use is widespread in prepared dishes, legumes and solid or pasty products with a high coefficient of expansion, although in America the old profile is still widely used, reflected in figure # 1.

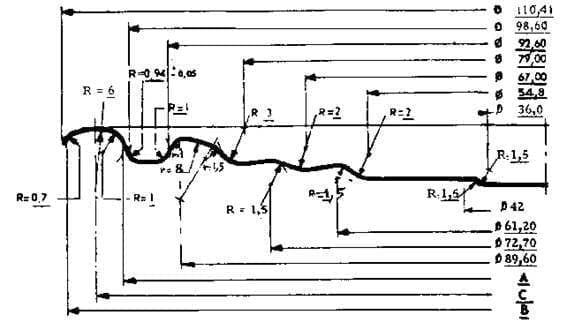

Figure 3 shows a profile similar to No. 2 but improved in its flexibility, based on an asymmetric peripheral bead.

Figure nº 3

These types of profiles have been applied to other diameters, especially the larger ones.

0 Comments