SUMMARY

Brief description of the different stages of tinplate manufacture, its structure and properties.

INTRODUCTION

With this work we intend to give some very general notions about tinplate. Being the basic raw material in the metallurgical sector, it is necessary to present even very briefly its properties, so that the uninitiated can have a minimum knowledge that will help you to enter better into this website, or to better interpret any writing related to this industry.

Tinplate is basically a sheet of steel coated with tin on both sides. Its beginnings date back almost 700 years. It has therefore a very long history, although it has been during the twentieth century when its elaboration technique has evolved in depth.

BASE STEEL

It is the body of the tinplate and determines its characteristics. The selection of the type of steel with which the tinplate is manufactured is defined by its final use. Several basic types of steel are used for its manufacture, such as MR, MC or L. They are steels with an amount of carbon between 0.05 to 0.12% and manganese from 0.30 to 0.6%. Sulphur should not exceed 0.05%. They can also contain small amounts of phosphorus, silicon… Later we will summarize in the form of a table the hardness of this steel depending on its use.

The following phases can be distinguished in its production:

– Platemaking

– Hot rolled

– Cold rolled

– Annealing

– Skin-Pass

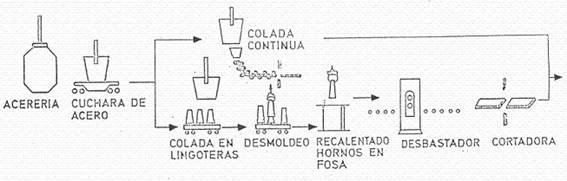

A) Manufacture of plates. It follows the common procedure for obtaining steel in a steelworks. There are two options: Process by continuous casting or ingot moulds. Figure 1 shows a general scheme of the process up to the completion of the plate.

Figure 1: Production of steel plates

In the case of ingot production, once the steel has been melted and the ingots have been formed, they are rolled into slabs, which are called “slabs”. This operation is carried out in reversible rolling mills. Some types also have lateral rollers that work simultaneously the four faces of the ingot, eliminating the operation of turning the ingot on its axis during this stage.

The final product of this operation, the slab, is 125 to 230 mm thick, the approximate width of the tinplate to be obtained and a length that depends on the size of the ingot.

The continuous casting process eliminates these different stages, developing the whole process in an uninterrupted way.

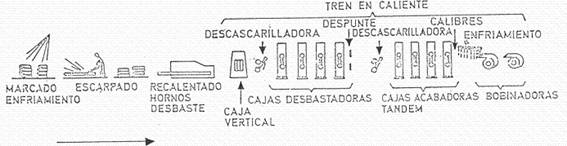

B) Hot rolled. This is the next step. Normally there is an intermediate stage, which consists of cooling and storing the plates, a sorting process, a surface preparation (scarfing) and a reheating of the plate to the temperature suitable for laminating. Diagram 2 shows the different stages of this process.

Figure no. 2: Hot rolling process

The hot rolling mill reduces the plate to a continuous strip of about 2 mm thickness. This train normally consists of two sections, a roughing section and a finishing section. It can be of a continuous or reversible type, depending on the capacity of the installation, etc.

At the end of this process the material is finished in the form of coils.

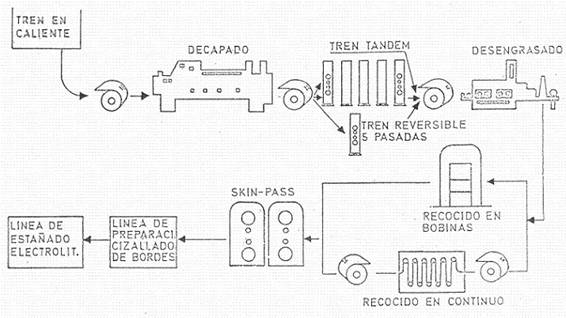

C) Cold rolled. The coils produced must be pickled and lubricated before cold rolling, which is usually carried out in a series of tanks containing hot dilute sulphuric acid. They are then washed, dried and lubricated with palm oil or other lubricant suitable for cold rolling. The pickling line is normally fitted with a circular cutter that cuts the edges, thus ensuring that they are suitable for cold reduction or cold rolling, and setting the maximum width of the tinplate to be obtained. A diagram of this phase is shown in Figure 3.

Figure No. 3: Cold rolling, annealing and skin-pass rolling of base steel

Cold rolling can be done in continuous (tandem) or reversible mills. Lubricants and coolants are used during this reduction, and the resulting thickness is very close to the desired final thickness in the case of reduced plain tinplate.

D) Annealing. The coil obtained is made of a very hard material subject to strong tensions and needs a suitable treatment to give it the necessary machinability. This treatment is called annealing and can be done continuously or in bell-type furnaces. See diagram nº 3. In both cases it is essential to remove the residues of the lubricating and cooling agents used previously, being the method used for this, consistent with the type of annealing to be done, normally electrolytic means are used.

E) Skin-pass. Next comes the tempering operation – surface treatment or finishing, called “skin-pas” or “temper rolling”. It is made by means of a reduction or lamination, without lubricant and very light, which usually does not exceed 2% in thickness. See diagram nº 3.

This stage gives a smooth surface, improves the shape and induces the necessary ductility in the material. In the case of double reduced tinplate, the tempering operation is replaced by a second gauge reduction or second rolling of approximately 33%, this time using surface lubricant.

It is common practice to prepare the coils prior to the tinning operation. It consists mainly of cutting the edges and eliminating poor quality or out-of-spec sections.

TINNING LINE

Currently the system used to deposit a thin layer of tin is electrolytic. In the past, another one was used by immersion in molten tin baths – tinplate coke – which became obsolete due to its high tin consumption.

There are several ways of proceeding in the manufacture of electrolytic tinplate. Basically it is a matter of passing the black sheet coil, already prepared, through a basin – electrolyte – of tin salts that incorporates several additives. The tin is taken from electrodes immersed in the bath.

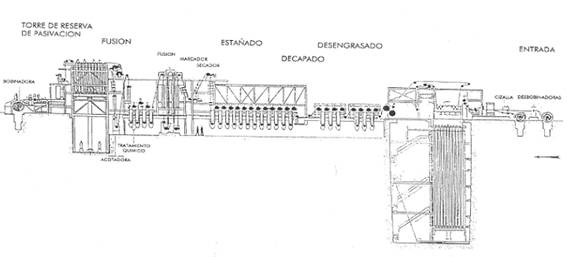

Simplifying the process, the following stages can be distinguished: See figure nº 4.

Figure no. 4: Electrolytic tinning line

– Unwinding and Preparation of the black sheet coils: Feeds continuously to the line, cutting the beginning and end of each coil and welding them. It has a web storage system that allows the accumulation of a certain amount of web, which feeds the line while the reel is being changed and spliced.

– Degreasing: Removes residual elements on the belt surface: lubricant residues, cooling agents, etc. It is obtained through chemical baths.

– Washing: Cleans the remains of the degreasing operation by means of water and/or steam jets.

– Pickling: Removes the iron oxide adhered to both sides of the coil and leaves the surface ready to receive the tin.

– Tin plating: It applies tin on both sides, there are several application procedures, acid process and alkaline or basic process, the latter in turn has two options, horizontal halogen lines and vertical alkaline lines. The most common are those that use the acid process. Electrolytes are your most delicate part.

– Tin plating: Its purpose is to give a shiny finish to the tinplate, as the simple electro-deposition of tin produces a micro-rough surface with a matte appearance. In this operation a layer of iron-tin alloy is produced, intermediate between the base steel and the superficial tin on each face, which increases the resistance of the tinplate to corrosive elements.

– Passivation: It basically consists of forming a layer of chromic oxide and tin. The methods used are various, chemical or electro-chemical, each designed to obtain special characteristics. This protective layer helps to prevent oxidation, not only during manufacture, but also in subsequent operations, such as varnishing. It has a decisive importance in the correct adhesion of the varnishes to the tinplate. The different passivation treatments produce different forms of attack or staining when the tinplate is subjected to contact with corrosive products or sulphur compounds.

– Oiling: A lubricant is applied to the surface of the tinplate. The purpose of this lubricant is not so much to protect the tinplate itself, but the passivation and not to counteract the properties of this is very light, so the most commonly used method of application is by electro-deposition, although it can be done by spraying or immersion. The most commonly used lubricant is dioctyl sebacate with a loading of 0.005 gms/m2.

– Cutting and packaging: The line ends with the making up of coils if the supply is in this way, or cutting into sheets. In this second case the installation is more complex as it involves a process of selection and separation of defective material.

TINPLATE STRUCTURE

The tin used in the protection of base steel is of high purity, with more than 99.80% tin and less than 0.04% of antimony, arsenic, bismuth, copper and other metals.

Tinplate does not only consist of the base steel and two thin layers of tin on both sides. We have already talked about the formation of iron-tin alloy zones, passivation and oiling. Therefore its final state is as shown in figure no. 5:

Figure no. 5: Tinplate cross-section

Electrolytic tinplate can be produced in various finishes, although three are the most common. A) Bright, which is the most common. B) Matte, or stone, which consists of tinning base steel with a rough surface and then not remelting the tin, and C) Same option B but re-melting the tin, which gives a shiny but non-reflective finish.

HARDNESS

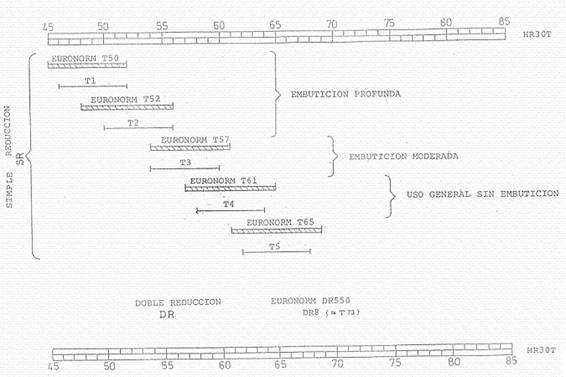

A key factor in the selection of the correct tinplate for each application is its hardness. It really comes down to the hardness of the base steel used in its manufacture. The “double reduced” type tinplate is harder than the “single reduced” type.

The hardness is evaluated on the HR 30T scale. In general, the whiter tinplates are used for packaging sausages or deep-drawn components. The hardest ones have their main application in the formation of cylindrical container bodies. The following table gives a general summary of the different types of tinplate classified according to their hardness.

Figure no. 6: Hardness grades and uses of tin plate

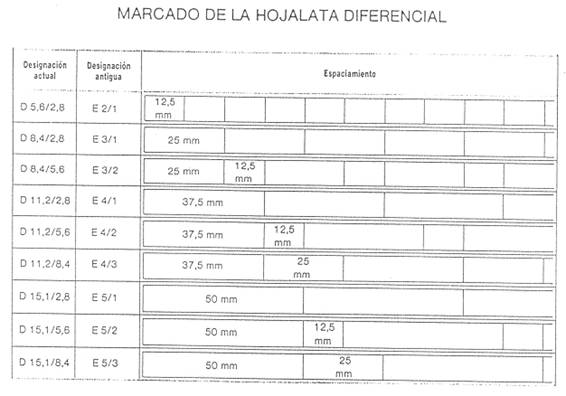

DIFFERENTIAL TINPLATE

When the tin coating is not the same on both sides, the tinplate is called differential. The tin load is measured in grs/m2. The first column of table nº 7 shows the most common tin plating combinations in differential tinplate. In the past, other types of designations were used, such as those indicated in the second column.

To easily identify the different types of coating, parallel lines of different sizes are marked on one of its faces, normally on the one with the largest coating. For this purpose, before tinning, these marks are made on the black sheet, which the thinness of the tin layer makes it possible to see underneath it.

Figure no. 7: Differential tinplate marking

ADVANTAGES OF TINPLATE

Among others can be listed:

– Presentation quality: Due to its metallic and shiny finish, it gives the packaging a pleasant appearance.

– Suitability for the manufacture of boats: Its properties of hardness, elasticity, heat conductivity, etc. make it the most appropriate material for this purpose.

– Corrosion resistance: The tin protection makes it the cheapest metallic material on the market that has high anti-corrosion properties.

– Lightness: The extreme thinness that can present their walls, allows to obtain containers of a very light weight. This is a clear advantage by eliminating dead weight in handling and transport.

– Sealing: Its mechanical properties facilitate the industrial seaming process, allowing a perfect seal, with a technology within the reach of any user.

– Sterilization: Its excellent resistance to external or internal pressures, as well as its good heat conduction, facilitate any type of sterilization process.

– Impermeability: It is a totally impermeable material, constituting a magnificent barrier to any type of external contamination.

0 Comments