Sometimes the question arises: Why is not the TFS material used in the manufacture of bodies for three-piece containers? This article responds to it.

INTRODUCTION

In the metal industry, electric welding is the generalized technique today for joining the lateral seam of the bodies for three-piece containers. This system of union has been in use for more than 40 years and has almost banished the classics that gave rise to the construction of the boats, such as the union engargolado – or agrafada – or overlapped.

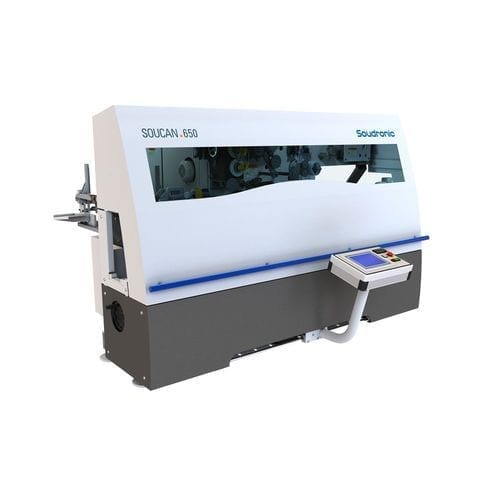

The different equipment that is on the market to make this welding are designed to use tinplate as the material to be joined. They are unable to work with other material, for example with TFS or with black plate. One question, which arises almost immediately, is why tinplate is valid and other materials are not?

WHY IS THE TIN WHAT IS THE IDEAL MATERIAL?

The reasons, for which the ideal material for the operation of the electric welders type Soudronic, is the tinplate, are derived from the fact that this material uses tin to protect the steel. Tin does only one aid work to facilitate this union, but it is not incorporated into welding.

In a tinplate body, it must not be forgotten that in the electric welding of the same, the parts that are welded together are steel with steel. Among the different types of base steels used to make it, the most common is the MR for its good anticorrosive properties

The tin protection that covers the steel, improves the contact surfaces to be welded, since being a soft metal, it initially fills the roughness when subjected to the pressure exerted by the welding rolls. Therefore, the electrical resistance in the overlapping zone decreases, since it is a good conductor of electricity. In other words, the tin initially makes a ductile joint effect between the two areas to be welded in steel

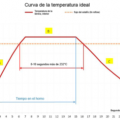

This tin subjected to the action of heat melts much earlier than steel. It melts at 232 Cº and the steel at approximately 1375 Cº Once melted, it must be expelled from the area to be welded, so that the two steel parts to be joined are intimately in contact, and thus get a good mixture of the crystals in the point of union The expulsion is achieved by the action of the welding pressure that the roldadas exert.

Experience shows that tinplate with high tinplate present difficulty in correctly expelling the entire tin. Those with low coating make it difficult to obtain a good initial contact surface. Therefore both cases can cause problems. Intermediate tinning is ideal.

WHY IS THE TFS NOT ADEQUATE?

The TFS material protects the steel based on a layer of chromium and chromium oxide. To know better the particularities of this, you can consult the work “TFS” published in the section “Technical information” of this same Web.

The characteristics of this metal are quite different from those of tin. On the one hand chromium and chromium oxide do not facilitate the passage of current, since its electrical conductivity is 20% less than that of tin. It is also a metal 5.7 times harder than tin and therefore is not able to perform the effect of ductile joint that the latter does.

In addition, its melting temperature is much higher than that of steel (1875º C), so it does not melt with the passage of current. This prevents the two steel areas to be joined by welding from coming directly into contact, and therefore welding does not occur.

When trying to weld TSF the only thing that is achieved is a series of irregular sparks, which damage the roldadas without actually welding. All this explains the difficulty of using TFS material.

The only way to use TFS is to previously scrape the chrome in the areas to be welded. Continental Can Company developed in the USA a technique for this that was called “conoweld”. It was used, initially, for the production of TFS beverage cans. To perform satisfactory welds with the first machines, it was required that the surface of the steel had no chrome coating in a width of about 2 mm. on each side of the edges that formed the seam. To apply it, Continental transformed conventional bodymakers into electric welding machines, incorporating rotating electrodes. This system had some success at the beginning, but later its use fell considerably

The TFS on the other hand is an excellent material for containers, funds or capsules obtained by embossing or die cutting.

0 Comments