In the heart of the Region of Murcia, Spain, Jomar, since its foundation in 1988, has been a pioneer in technological innovation and improvement of production processes in the industrial sector. Since then, its vast experience has enabled it to offer its customers state-of-the-art technological solutions to solve production challenges. With a team of highly trained professionals, Jomar S.L. provides an integral service.

“Jomar S.L. is a company with a strong legacy and a global presence. We have managed to expand our presence internationally reaching a footprint in more than 15 countries. In addition, more than forty highly committed workers make up our talented team, all of them passionate about innovation and always providing a service based on excellence,” the company said.

“For more than thirty years, we have acquired extensive experience in the industry, which has allowed us to gain in-depth knowledge and technical skills to meet any challenge that may arise. The main gratification for us is the satisfaction of our clients, and that is why we have worked with more than 200 companies providing technological solutions and comprehensive 360 assistance,” added the same sources.

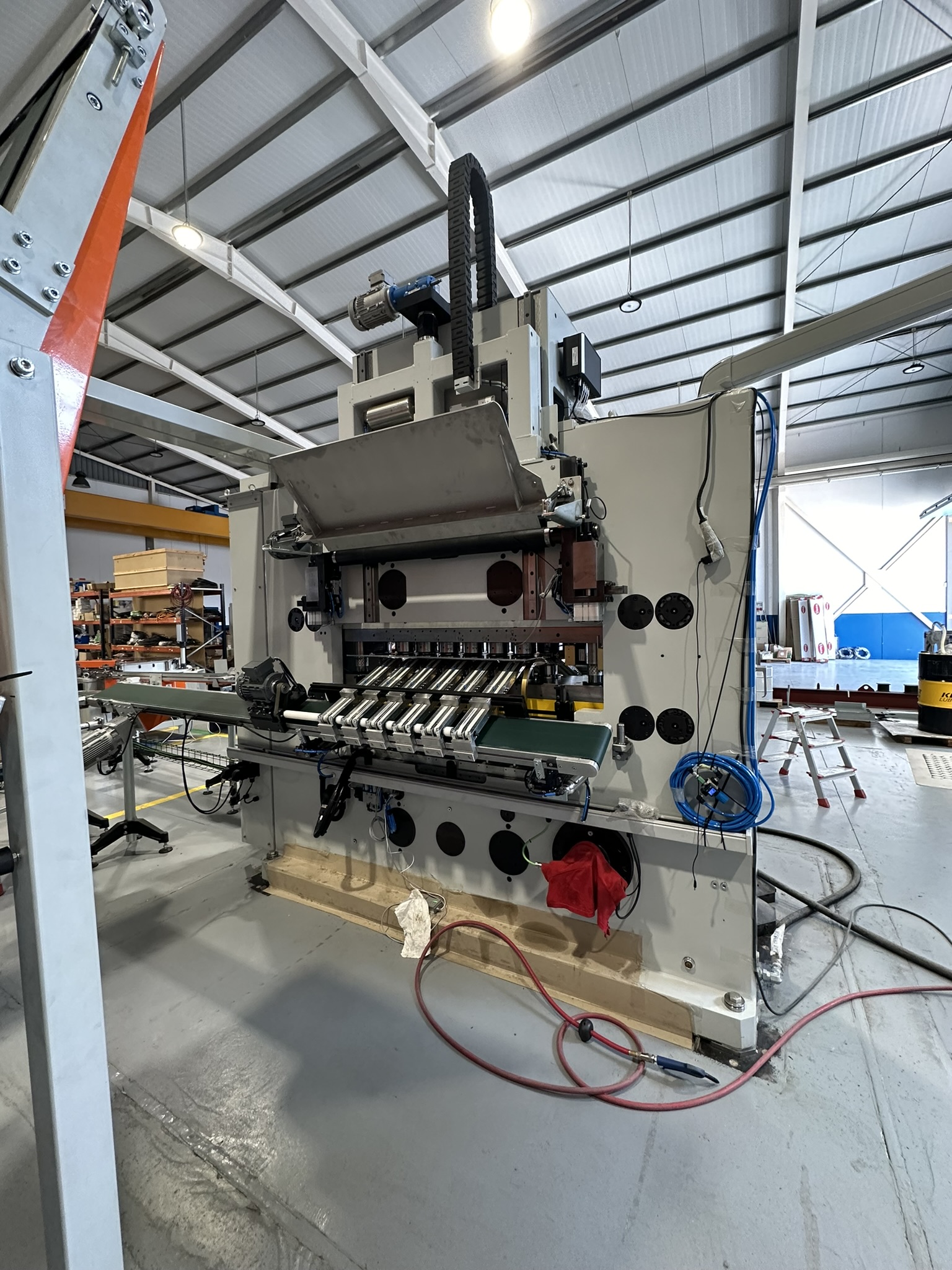

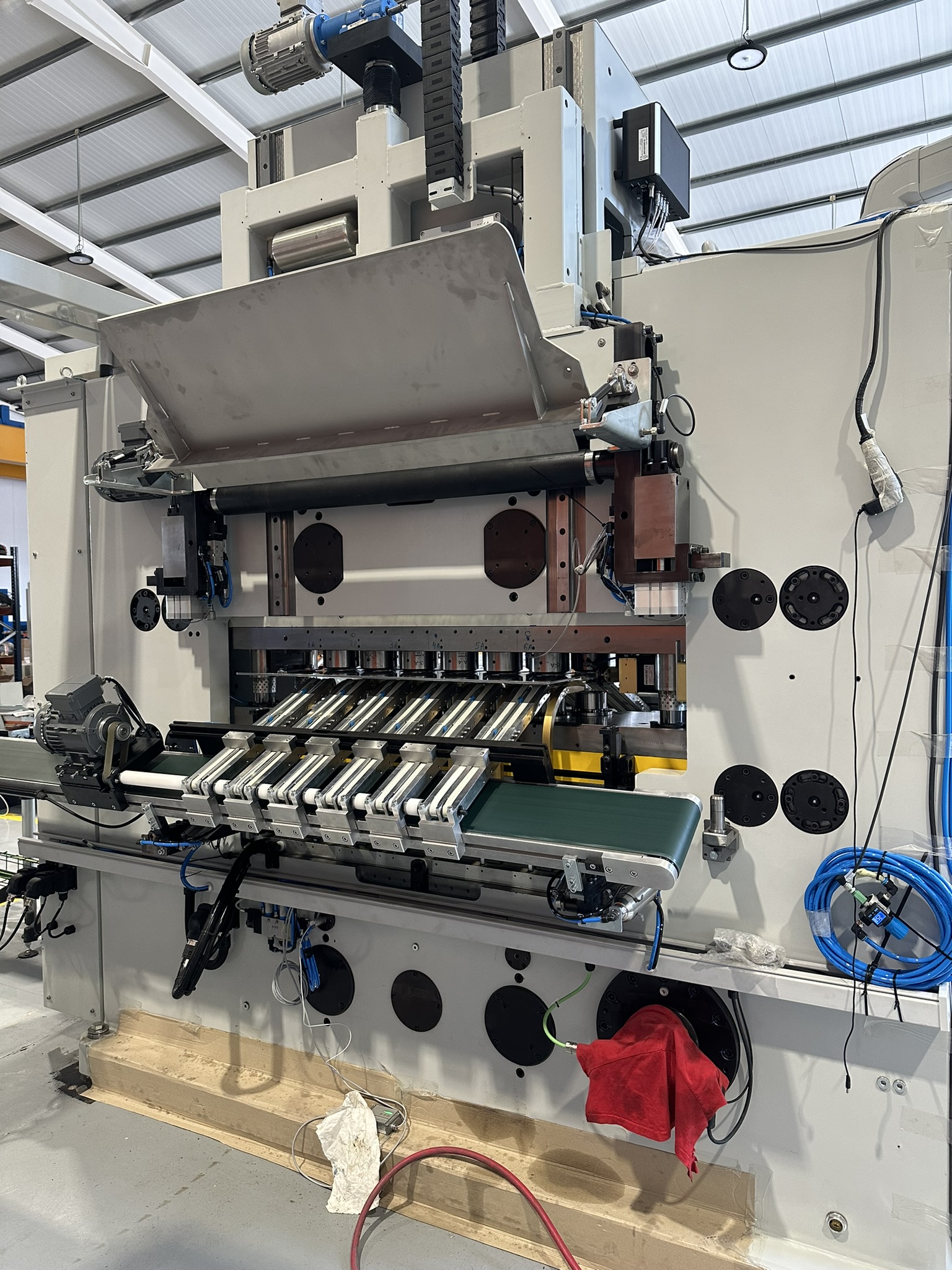

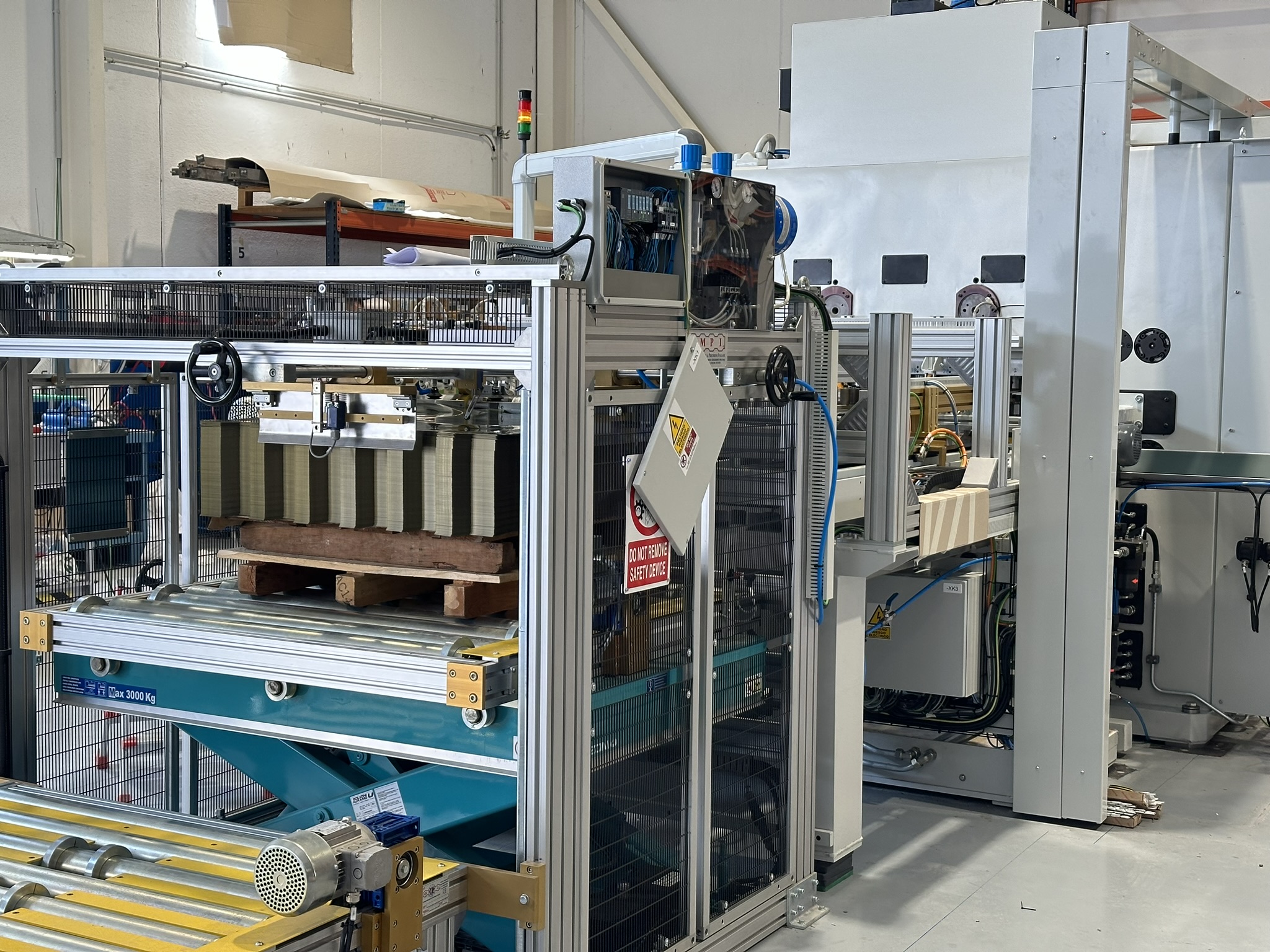

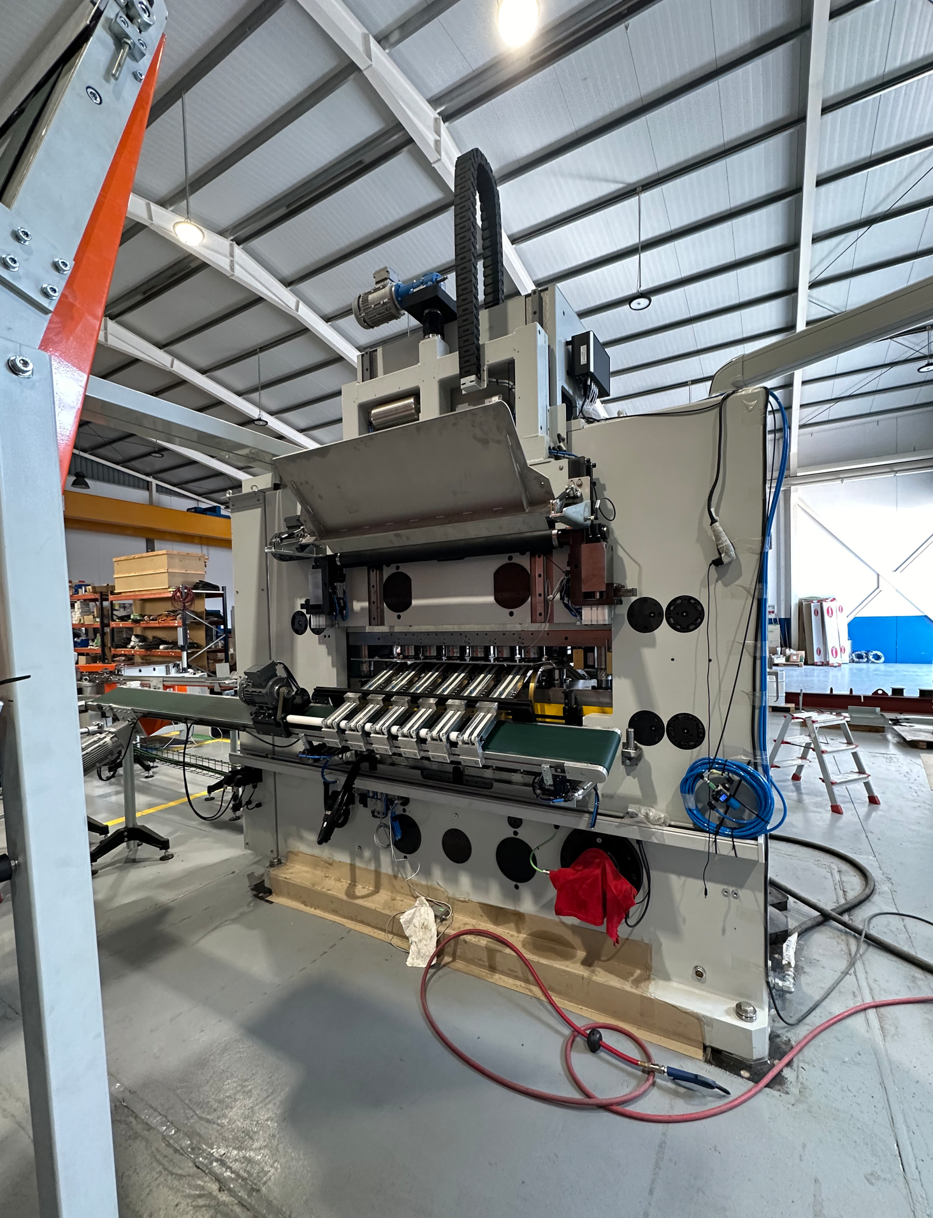

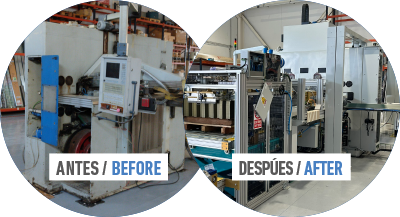

In addition, they have recently embarked on an exciting journey towards Industry 4.0 in collaboration with Auxiliar Conservera. The project consists of reconditioning a multi-slide press manufactured in 1993, transforming it into a modern and efficient machine, ready to face the challenges of the future.

The press, originally equipped with 11 dies (two of which were disabled) and a capacity of 150 tons, required a major upgrade. Its move to Jomar’s facilities marked the beginning of a painstaking transformation

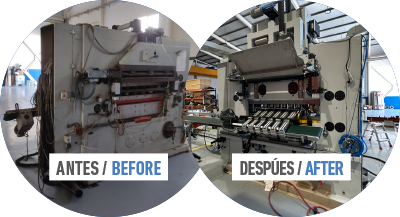

During this process, the press was disassembled following a thorough process that included a detailed visual inspection. “Identifying and classifying each item allowed for in-depth analysis, which proved to be an excellent opportunity to gain valuable information. Gaining a broad knowledge about the machine, including its parts and how it works. In addition, the idea is to lay the foundation for possible future improvements, emphasizing accessibility, functionality and ease of use,” they remarked.

Following this phase, a detailed maintenance manual will be created to assist in the care and performance improvement of the press. The objective is to find the nearest manufacturer to facilitate the management of spare parts and technical assistance.

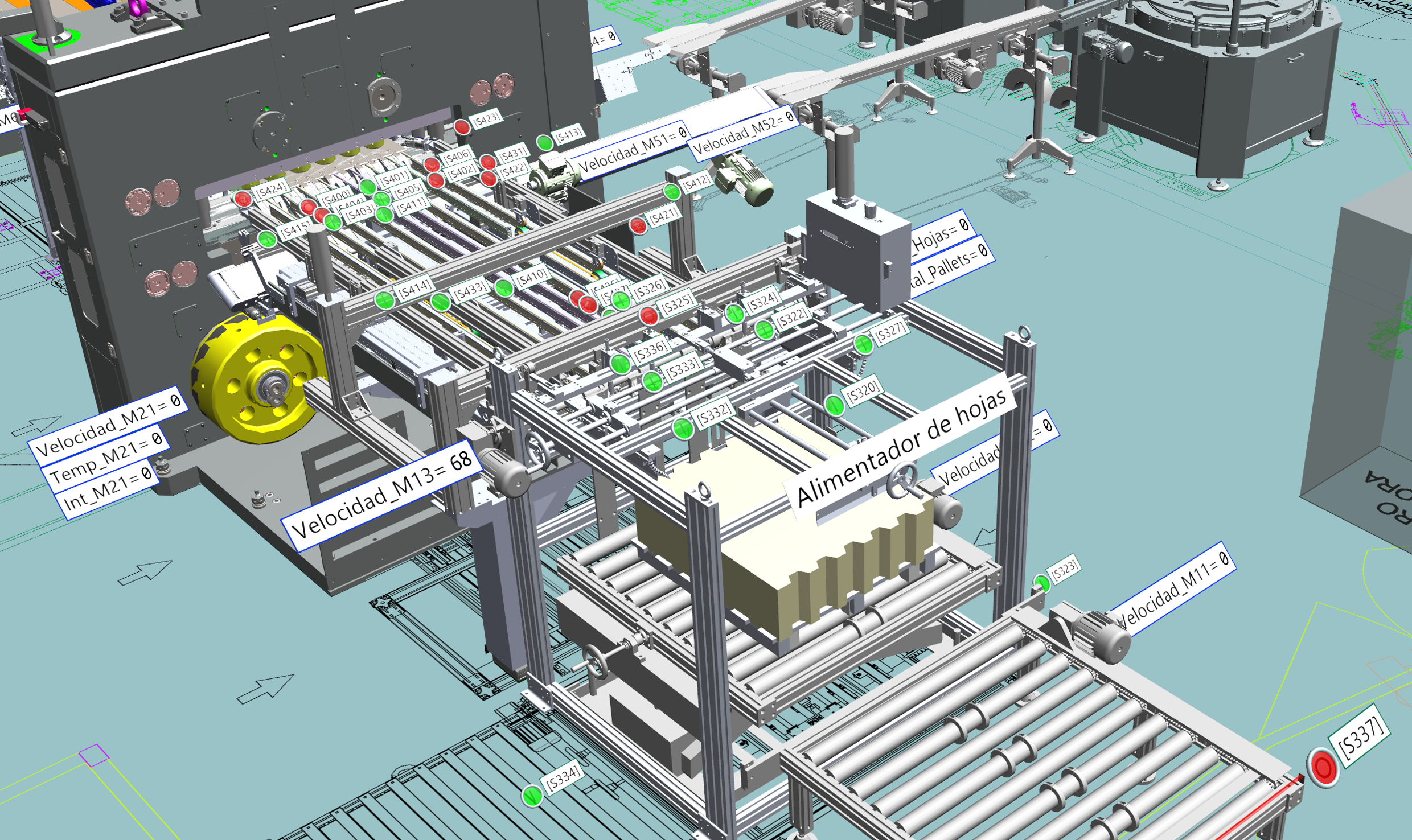

During this process, not only were the press components renewed, but advanced technologies were also incorporated as part of the reconditioning process. “The electrical and electronic system has been upgraded with the incorporation of new servomotors, frequency inverters and an advanced PLC that allow precise and efficient control. This represents a major modernization of the system, as the hydraulic and lubrication system will be improved, with the aim of optimizing its control throughout the production process and achieving greater energy efficiency,” the company explained, adding that “the use of specialized equipment and sensors will allow real-time information to be collected and the performance of the press machine to be evaluated.

The end of this innovative project has generated a new multi-slide press, ready to face the challenges of Industry 4.0. Another achievement is that a significant improvement in the quality of parts has also been noted, with a considerable reduction in the rejects that previously occurred, while maintenance costs have been significantly reduced thanks to the updating and standardization of components, as well as preventive maintenance.

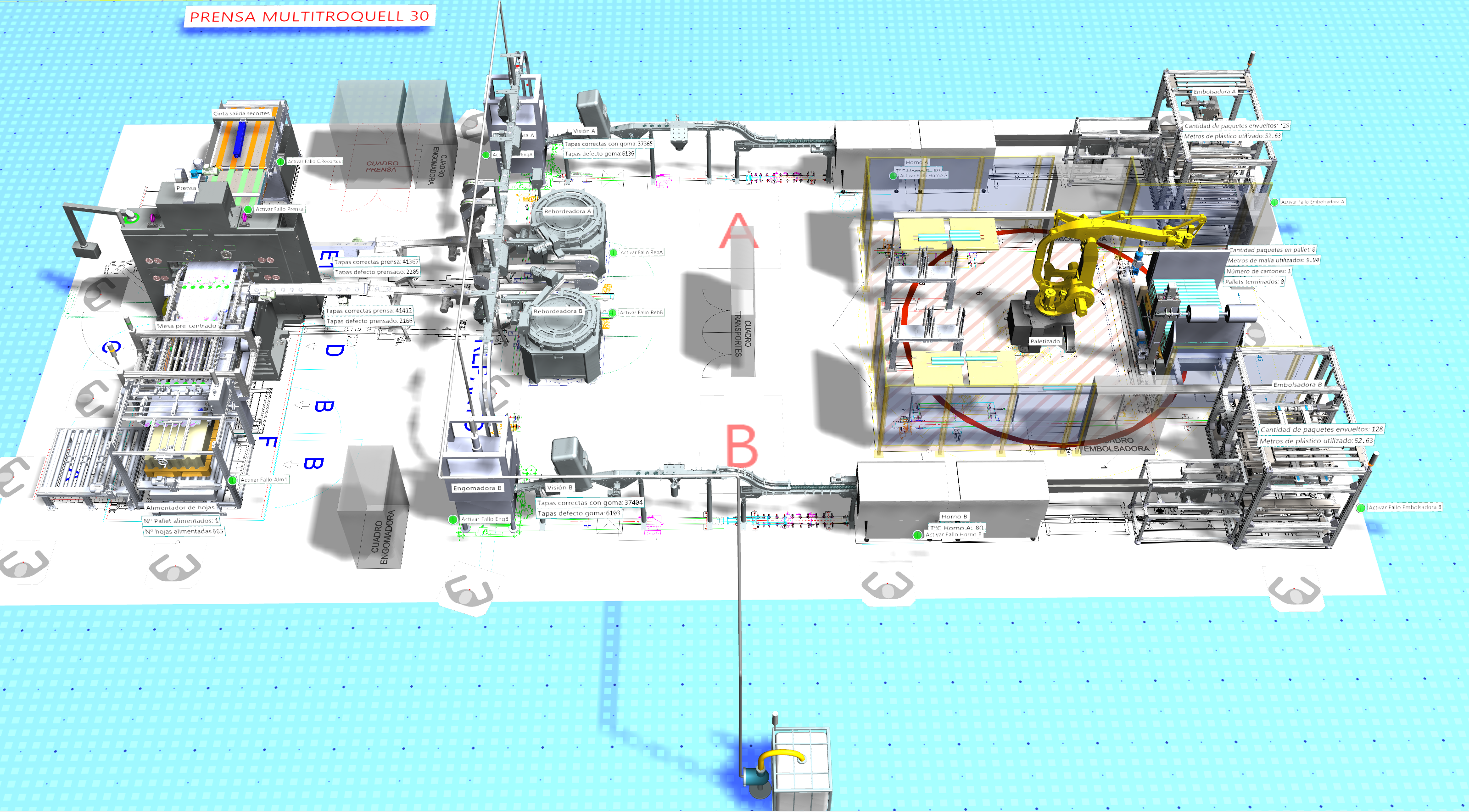

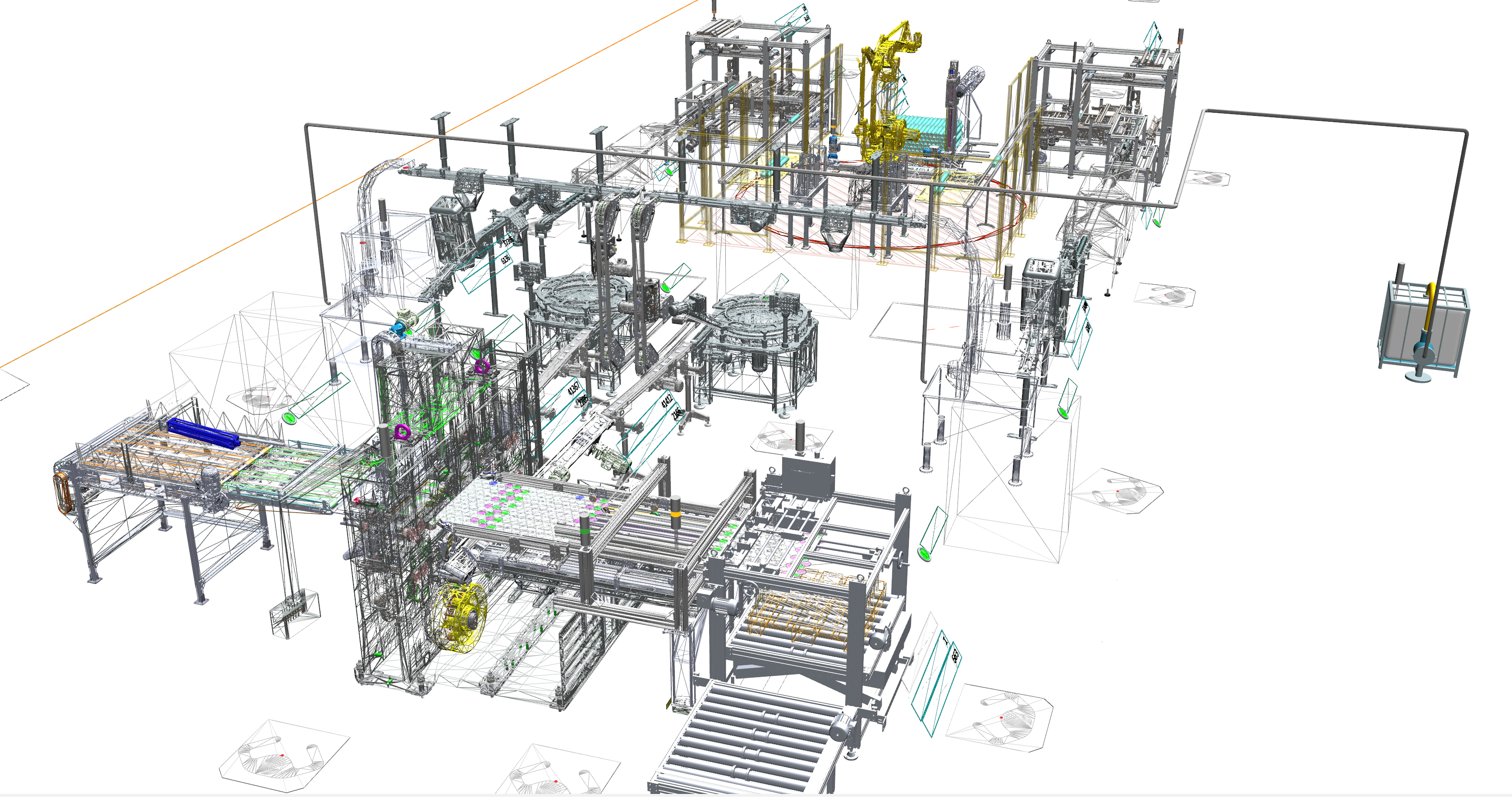

On the other hand, Jomar has advanced in its digitalization process by implementing a ‘Digital Twin’ of the production system of its entire line, thanks to Siemens Plant Simulation technology. This tool provides a multitude of advantages.

“By using virtual technology, the production process can be imitated and examined in a virtual environment in order to improve the sequence of operations, detect possible obstacles and analyze various situations in relation to production. Before carrying out the physical implementation of the line, it is important to validate and improve its design to reduce the risk of making mistakes and avoid additional costs,” they added.

The collaboration between Jomar and Auxiliar Conservera has resulted in a project that demonstrates how experience and innovation can be a driving force in the transformation to Industry 4.0. Both companies have demonstrated that machine reconditioning is not only possible, but can also lead to higher levels of efficiency, competitiveness and sustainability in the industry.

Jomar also carries out engineering projects, technical reports and legalizations for the industry. As authorized low voltage installers, they verify the electrical installations in public places, premises with fire and explosion risk, and premises with special characteristics.

They also carry out overhead line and transformer station projects. In addition, as a high voltage maintenance company, we perform the Periodic Regulatory Inspection of Transformer Substations.

The production challenges faced by Jomar S.L. are diverse and require innovative technological solutions. Some of these challenges are process optimization, improving efficiency and reducing production times, which is essential to maximize productivity.

“In the case of machinery upgrading, modernization of equipment and machinery is essential to remain competitive. Retrofitting older machines, such as the multitroch press, is an important step in adapting to changing market demands,” they also detailed.

Industry 4.0 promotes intelligent automation, which is why Jomar S.L. could face the challenge of implementing automated systems that improve accuracy, reduce errors and increase production speed. In addition, with increasing digitization, managing large volumes of data becomes crucial. At Jomar S.L., personnel training is also key. “Keeping employees up to date with the latest technologies and processes is essential. Ongoing training ensures that the team is prepared to meet technical challenges that may arise,” they concluded.

In short, Jomar S.L. manages to balance tradition with innovation, embracing new technologies while leveraging its legacy of industry experience to continue to grow within its sector.