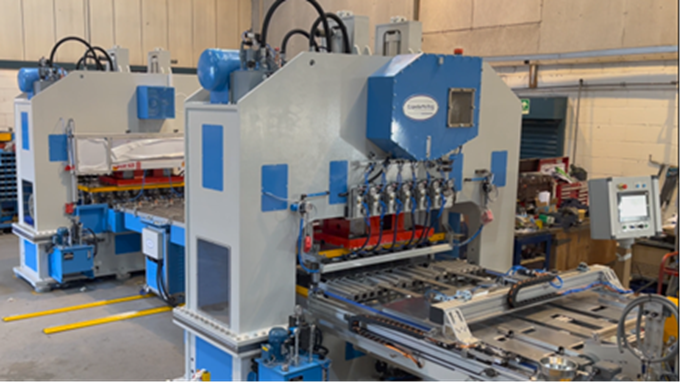

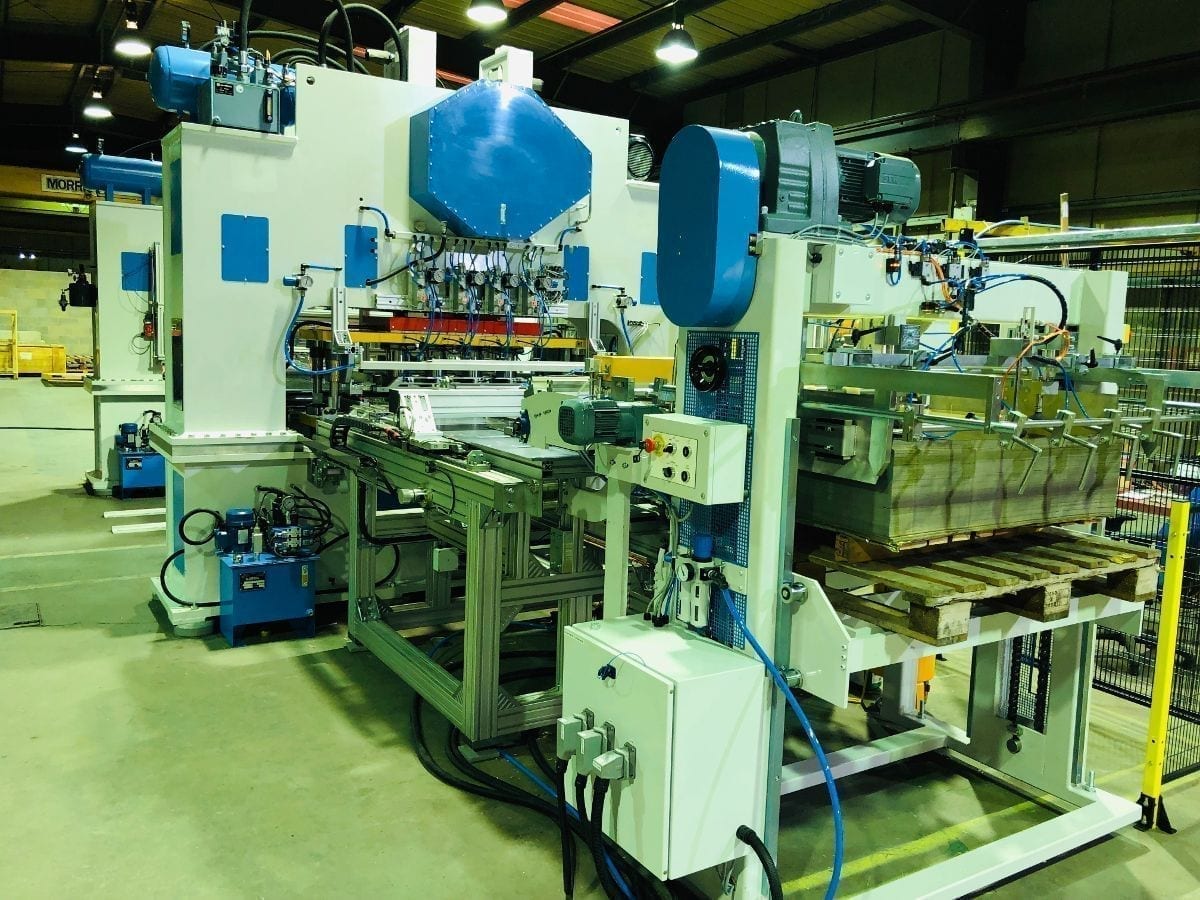

CEPEDAMELTOG, a leading press manufacturer, has announced the addition of hairless technology to its press lines. The company’s presses are specially designed to manufacture screw caps, PT caps or other cap variants that require different crimping steps. Hairless technology will be included in its lines as part of the company’s rapid die change process.

The quick-change process uses technologies transferred from the automotive industry, in particular SMED which stands for ‘die change in minutes’, which conceives die cutting as a ‘cartridge’ type concept with many common features, promoting fast changeovers. This new addition to their press lines will make the production process faster and more efficient.

CEPEDAMELTOG’s range of presses includes the T300, a compact vertical bridge press synchronized with two index rotary tables and with an output of up to 350 cpm (the fastest on the market) including the liner system and 3 different steps for the formation of different types of caps. The SUPERCAP® press uses a specially framed double-sided press with extra-long linear guides for superior plunger accuracy that incorporates a multi-way linear cap transfer system and has an output of up to 1800 cpm, making it one of the fastest on the market.

With the addition of hairless technology, CEPEDAMELTOG is demonstrating its commitment to providing its customers with the latest technology and innovation in the industry. This new tool will help your customers increase production efficiency and reduce downtime, ultimately leading to higher profits.