CORROSION PROCESSES IN EASY-OPEN CONTAINERS AND LIDS: TECHNICAL GUIDE

1. INTRODUCTION: THE NATURE OF CORROSION IN METAL CONTAINERS Corrosion is technically defined as the slow destruction...

EUROPEAN METAL CANS MARKET, BY COUNTRY

ANALYSIS AND FORECASTS OF THE EUROPEAN METAL CANS MARKET The metal cans market in Europe has experienced steady growth...

ANALYSIS AND FORECASTS OF THE METAL CANS MARKET IN ASIA-PACIFIC

The metal packaging market in Asia-Pacific has experienced significant growth in recent years, driven by various...

EUROPEAN METAL CANS MARKET, BY COUNTRY

ANALYSIS AND FORECASTS OF THE EUROPEAN METAL CANS MARKET The metal cans market in Europe has experienced steady growth...

ANALYSIS AND FORECASTS OF THE METAL CANS MARKET IN ASIA-PACIFIC

The metal packaging market in Asia-Pacific has experienced significant growth in recent years, driven by various...

ANALYSIS AND FORECAST OF THE LATIN AMERICAN METAL PACKAGING MARKET

ANALYSIS AND FORECASTS OF THE LATIN AMERICAN METAL PACKAGING MARKET The Latin American metal packaging market is...

DIMENSIONAL CONTROL OF BOTTOMS OR LIDS

INTRODUCTION A In the metalworking industry, the purchase or exchange of ready-made components (phons, easy-open caps,...

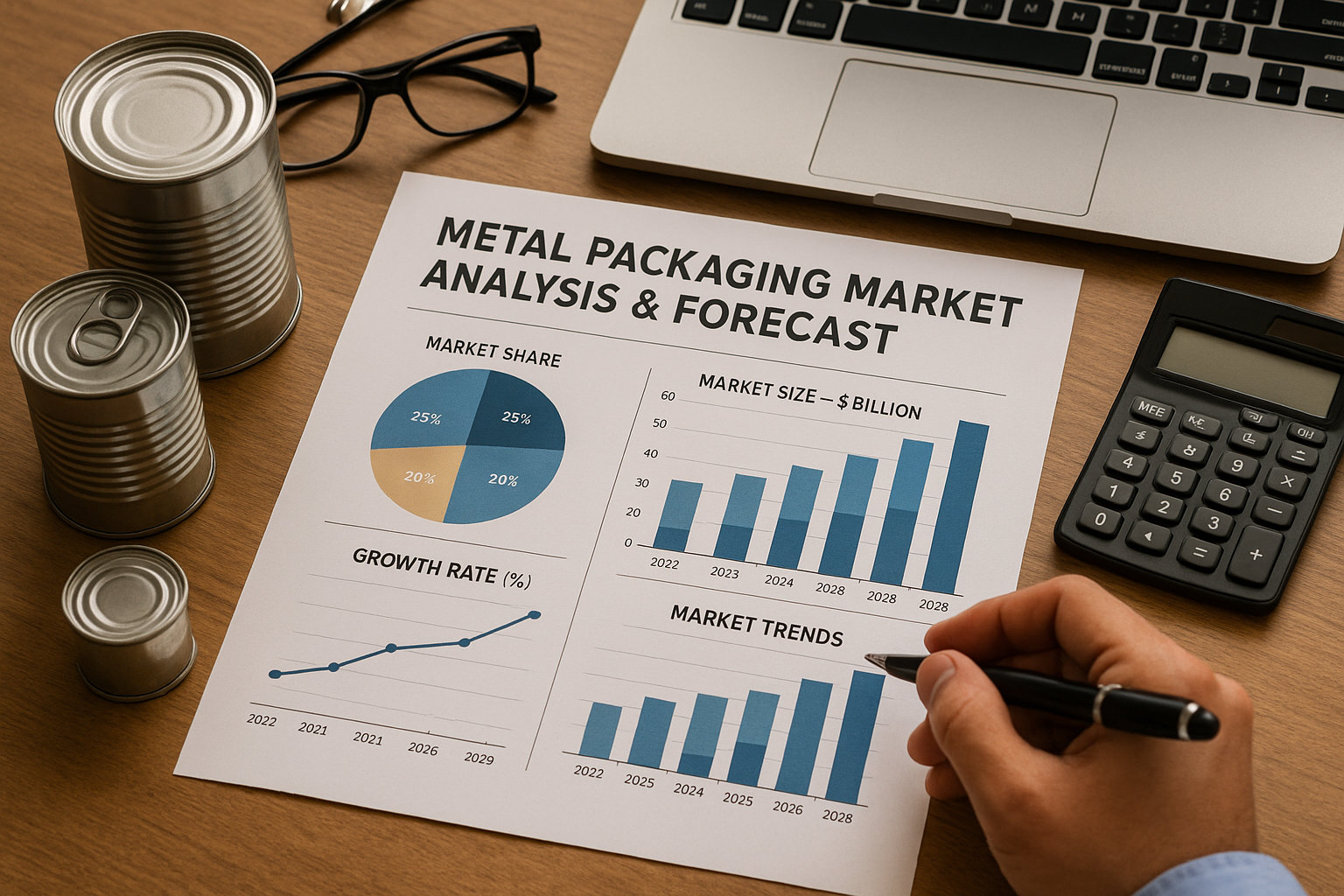

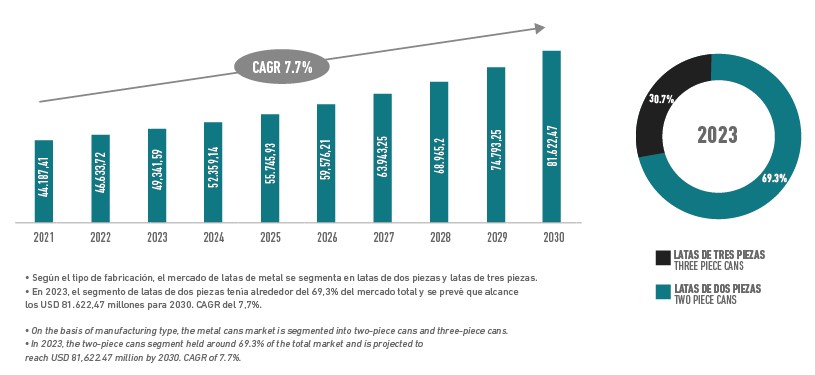

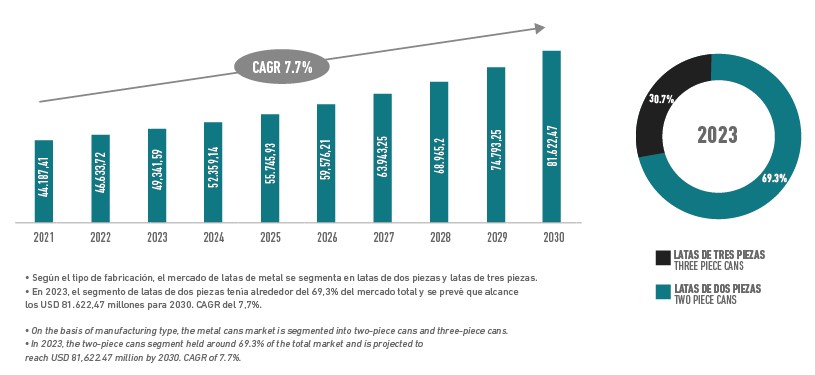

Global Metal Cans Market, by Type of Manufacture

Two-Piece Metal Cans Market Analysis and Forecast Two-piece cans, a prominent segment in the metal can market, are...

FUNDAMENTALS OF ELECTRIC WELDING

Index:– Chronology– Fundamentals of electric welding 1º.- CHRONOLOGYa) STARTIn the early 1960s, two different welding...

interior powder coating and curing with electrostatic powder

Electrostatic powder coating and interior curing is a process that offers several important advantages and features...

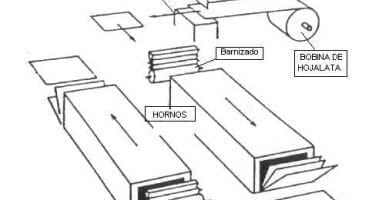

exterior coating

Objectives of Exterior Varnishing: Provide protection against corrosion. To give a good appearance to the exterior,...

ensure adherence of dust on a container that has an internal film or coating

To ensure powder adhesion on a container that already has an internal film or coating, several key factors must be...

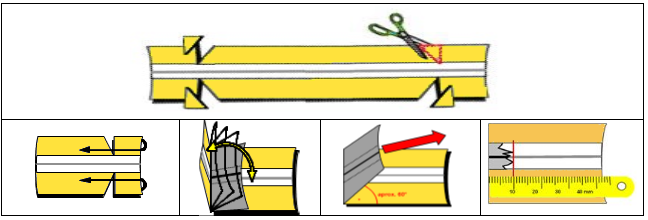

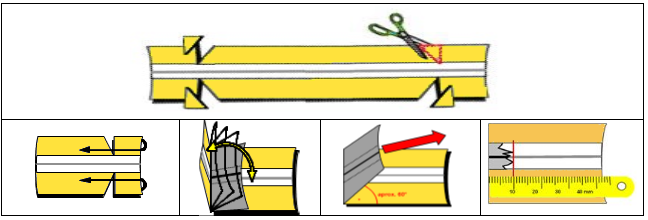

shear blade maintenance

To properly maintain the blades of a shear, it is essential to follow a series of steps and recommendations to ensure...

white powder inside metal container

How to improve powder curing and adhesion to the container Lack of powder adhesion to the container can be due to...

epoxy resins for food products

Epoxy resins, derived from the condensation reaction between epichlorohydrin and biphenol A (diphenol propane), form...

information about twist off caps

information about twist off caps Twist-off lids are metal lids used to close glass or plastic jars, mainly intended...

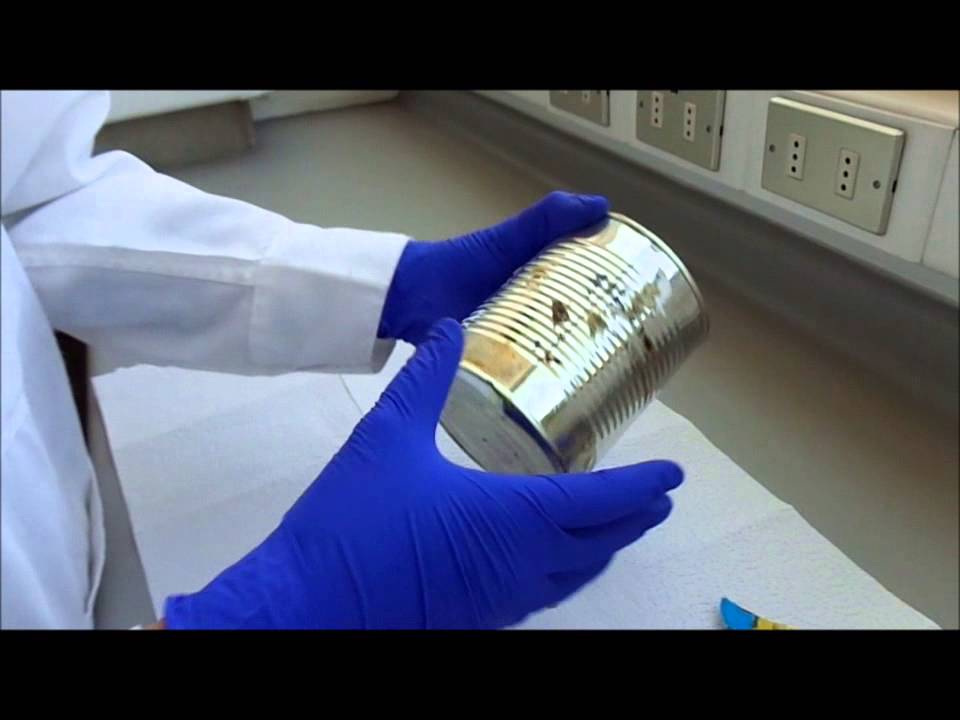

axial and radial strength tests on tinplate cans

axial and radial strength tests on tinplate cans Axial and radial strength tests on tinplate cans are important to...

canning process

The food canning process involves several critical steps to ensure the quality and safety of the final product. Here...

manufacture of a traditional cover

The technical process for the manufacture of a traditional closure is not explicitly detailed in the information...

Peel Off cap

A peel-off closure is a type of closure used on metal containers that allows a complete and simple opening of the...

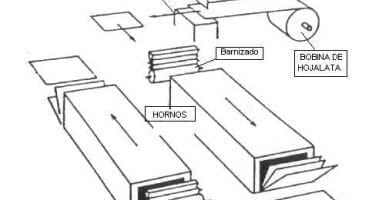

Tinplate Manufacturing Process

Steel ProductionThe tinplate production process begins in the blast furnace and tin smelter, although in practice, it...

Annealing and Heat Treatment of Metals: Comparison between Bell Annealing (BA) and Continuous Annealing (CA)

Annealing and Heat Treatment of Metals: Comparison between Bell Annealing (BA) and Continuous Annealing (CA) Annealing...

Steel Production: The Foundation of Tinplate in the Metal Packaging Industry

Steel Production: The Foundation of Tinplate in the Metal Packaging Industry Tinplate is a widely used material in the...

Tinplate Passivation: Surface Protection against Oxidation and Sulfidation

Tinplate Passivation: Surface Protection against Oxidation and Sulfidation Tinplate, a material widely used in the...

Cold Rolling of Tinplate for Metallic Containers

Cold Rolling of Tinplate for Metallic Containers Cold rolling is an essential process in the manufacture of tinplate,...

Hot Rolling of Tinplate: Technical Process and Considerations

Hot Rolling of Tinplate: Technical Process and Considerations Hot rolling is a crucial process in the manufacture of...

Tinplate Electrolytic Tin Plating for the Metal Packaging Industry

Tinplate Electrolytic Tin Plating for the Metal Packaging Industry Tinplate is a key material in the metal packaging...

Oiling (DOS), a crucial step in canmaking

Oiling (DOS), a crucial step in canmaking In the metal packaging industry, oiling is an essential process carried out...

Pickling on Tinplate: A Key Process in the Metal Packaging Industry

Pickling on Tinplate: A Key Process in the Metal Packaging Industry Pickling is a fundamental step in the production...

Tinplate Tempering in the Manufacture of Metal Containers

Tinplate Tempering in the Manufacture of Metal Containers Tempering is a critical process in the manufacture of...

Tinplate in the Metal Packaging Industry: Manufacturing Processes and Applications

Tinplate in the Metal Packaging Industry: Manufacturing Processes and Applications Tinplate is an essential material...

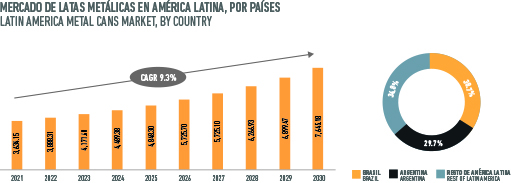

Latin America metal can market forecast to 2030

Brazil accounts for 38.7% of the market share, followed by Argentina with 34%, while the remaining countries account...

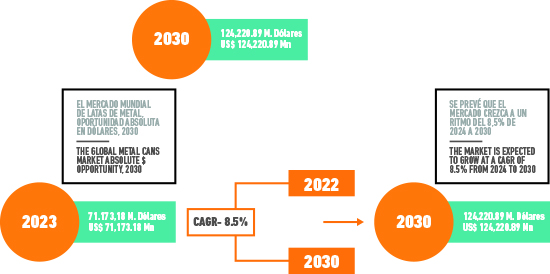

Market Study 2030 Metal Packaging

Market overview Metal cans are containers made mainly of materials such as aluminum or steel, designed for packaging...

Welding on Tinplate Cans

Welding on Tinplate Cans Introduction Brief description of the importance of welding in the manufacture of cans....

Innovations in the Use of Aluminum for Food Preservation

Introduction Aluminum is a widely used material in the food preservation industry due to its excellent barrier...

Coatings for metal containers

Coatings for metal containers include a variety of chemical compounds designed to protect both the contents of the...

Analysis, coatings and physical properties of the lids

Physical properties of easy open lids: Easy open closures, also known as easy open closures, have several important...

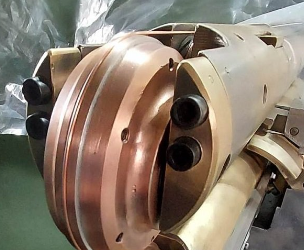

How often is it recommended to rectify the welding rollers?

Grinding of welding rollers is a critical maintenance procedure to ensure weld quality in metal container production....

Causes of wire slippage on welding

Causes of wire slippage on the weld in the welding process of food cans, here are some possible causes. Causes of wire...

DISCON Welding Rollers at Soudronic

Introduction In the manufacturing process of metal containers, such as three-piece cans, welding plays a crucial role...

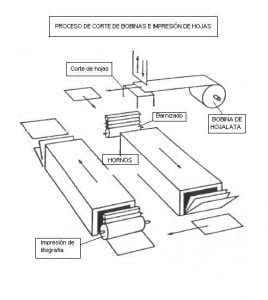

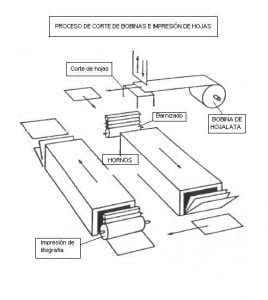

Cutting process in the manufacture of metallic containers

Cutting process in the manufacture of metallic containers The cutting process in the manufacture of tinplate...

How to get a correct rubberizing of a lid

How to get a correct rubberizing of a lid In order to achieve a correct rubberizing of a round cap, it is considered...

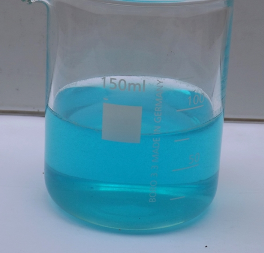

Copper sulfate test in metal containers

The copper sulfate test is a test used in the packaging industry to detect the presence of pores, cracks, or any...

The Blushing Phenomenon in the Manufacture of Tinplate Food Cans

Blushing is a phenomenon that occurs during the manufacturing process of tinplate food cans, specifically during the...

Application, Curing and Main Defects of Electrostatic Powder in 3-Piece Containers

IntroductionElectrostatic powder is a polyester resin used in the metal packaging industry to protect welds from...

can with whitish exterior appearance

The appearance of white spots on the outside of cans may be due to the formation of deposits of dissolved salts,...

how can I improve the double seam of the cans?

To improve the double seam in canmaking, there are several aspects that can be considered based on the information...

can and lid sealing compound

Sealing compound or sealant is a special material that coats the inside of the curl of a can lid. When the can is...

What are the most common dimensions / formats of seafood cans?

The most common dimensions and formats of seafood cans, according to the information provided, include a wide variety...

What are the basic rules for applying sealing compound?

The basic rules for applying sealing compound to can ends are as follows: The weight of the compound should be...

CORROSION PROCESSES IN EASY-OPEN CONTAINERS AND LIDS: TECHNICAL GUIDE

1. INTRODUCTION: THE NATURE OF CORROSION IN METAL CONTAINERS Corrosion is technically defined as the slow destruction...

EUROPEAN METAL CANS MARKET, BY COUNTRY

ANALYSIS AND FORECASTS OF THE EUROPEAN METAL CANS MARKET The metal cans market in Europe has experienced steady growth...

ANALYSIS AND FORECASTS OF THE METAL CANS MARKET IN ASIA-PACIFIC

The metal packaging market in Asia-Pacific has experienced significant growth in recent years, driven by various...

EUROPEAN METAL CANS MARKET, BY COUNTRY

ANALYSIS AND FORECASTS OF THE EUROPEAN METAL CANS MARKET The metal cans market in Europe has experienced steady growth...

ANALYSIS AND FORECASTS OF THE METAL CANS MARKET IN ASIA-PACIFIC

The metal packaging market in Asia-Pacific has experienced significant growth in recent years, driven by various...

ANALYSIS AND FORECAST OF THE LATIN AMERICAN METAL PACKAGING MARKET

ANALYSIS AND FORECASTS OF THE LATIN AMERICAN METAL PACKAGING MARKET The Latin American metal packaging market is...

DIMENSIONAL CONTROL OF BOTTOMS OR LIDS

INTRODUCTION A In the metalworking industry, the purchase or exchange of ready-made components (phons, easy-open caps,...

Global Metal Cans Market, by Type of Manufacture

Two-Piece Metal Cans Market Analysis and Forecast Two-piece cans, a prominent segment in the metal can market, are...

FUNDAMENTALS OF ELECTRIC WELDING

Index:– Chronology– Fundamentals of electric welding 1º.- CHRONOLOGYa) STARTIn the early 1960s, two different welding...

interior powder coating and curing with electrostatic powder

Electrostatic powder coating and interior curing is a process that offers several important advantages and features...

exterior coating

Objectives of Exterior Varnishing: Provide protection against corrosion. To give a good appearance to the exterior,...

ensure adherence of dust on a container that has an internal film or coating

To ensure powder adhesion on a container that already has an internal film or coating, several key factors must be...

shear blade maintenance

To properly maintain the blades of a shear, it is essential to follow a series of steps and recommendations to ensure...

white powder inside metal container

How to improve powder curing and adhesion to the container Lack of powder adhesion to the container can be due to...

epoxy resins for food products

Epoxy resins, derived from the condensation reaction between epichlorohydrin and biphenol A (diphenol propane), form...

information about twist off caps

information about twist off caps Twist-off lids are metal lids used to close glass or plastic jars, mainly intended...

axial and radial strength tests on tinplate cans

axial and radial strength tests on tinplate cans Axial and radial strength tests on tinplate cans are important to...

canning process

The food canning process involves several critical steps to ensure the quality and safety of the final product. Here...

manufacture of a traditional cover

The technical process for the manufacture of a traditional closure is not explicitly detailed in the information...

Peel Off cap

A peel-off closure is a type of closure used on metal containers that allows a complete and simple opening of the...

Tinplate Manufacturing Process

Steel ProductionThe tinplate production process begins in the blast furnace and tin smelter, although in practice, it...

Annealing and Heat Treatment of Metals: Comparison between Bell Annealing (BA) and Continuous Annealing (CA)

Annealing and Heat Treatment of Metals: Comparison between Bell Annealing (BA) and Continuous Annealing (CA) Annealing...

Steel Production: The Foundation of Tinplate in the Metal Packaging Industry

Steel Production: The Foundation of Tinplate in the Metal Packaging Industry Tinplate is a widely used material in the...

Tinplate Passivation: Surface Protection against Oxidation and Sulfidation

Tinplate Passivation: Surface Protection against Oxidation and Sulfidation Tinplate, a material widely used in the...

Cold Rolling of Tinplate for Metallic Containers

Cold Rolling of Tinplate for Metallic Containers Cold rolling is an essential process in the manufacture of tinplate,...

Hot Rolling of Tinplate: Technical Process and Considerations

Hot Rolling of Tinplate: Technical Process and Considerations Hot rolling is a crucial process in the manufacture of...

Tinplate Electrolytic Tin Plating for the Metal Packaging Industry

Tinplate Electrolytic Tin Plating for the Metal Packaging Industry Tinplate is a key material in the metal packaging...

Oiling (DOS), a crucial step in canmaking

Oiling (DOS), a crucial step in canmaking In the metal packaging industry, oiling is an essential process carried out...

Pickling on Tinplate: A Key Process in the Metal Packaging Industry

Pickling on Tinplate: A Key Process in the Metal Packaging Industry Pickling is a fundamental step in the production...

Tinplate Tempering in the Manufacture of Metal Containers

Tinplate Tempering in the Manufacture of Metal Containers Tempering is a critical process in the manufacture of...