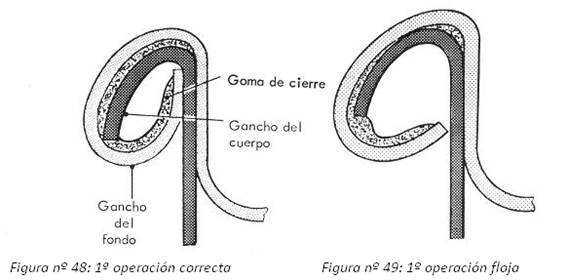

The closure specifications for two-piece 52 (202) diameter containers used in the packaging of beer and carbonated beverages are set out below.

The attached documentation is a courtesy of the company Crown Bevcan España S.L. whose central manufacturing plant is located in P.I. El Sequero 26509 Agoncillo (La Rioja-Spain) Tel: 941431026

The multinational Crown is the current owner of the network of companies that in 1969 started in Spain, in its plant in Quart de Poblet (Valencia), the manufacture of metal containers for the packaging of beer. Likewise, its Technical Assistance Service was the one who advised all its customers on the use of the new type of packaging. (The original package was 3 pieces with tin-lead solder)

CLOSURE SPECIFICATIONS FOR DIAMETER 52 (202) BEVERAGE CONTAINERS

0 Comments