The way to prepare a “product file” is developed, which allows to have at the foot of the line, the appropriate information for the correct manufacture of a package of the type inlaid, low height.

INTRODUCTION

We have previously discussed the reasons why it is very interesting to have a “product file”, so we will not repeat them again, they can consult the work:

– Product technical sheet: Three pieces packaging

From the production point of view, a simple material is needed at the foot of the machine, but with the most complete information possible of the product that is being manufactured at that moment. To cover this need, the Technical Office prepares the “Product Card”, which provides the necessary data so that in each phase or operation the necessary information is available to carry it out properly.

For example, in the case of the manufacture of a low-height embossed type container, the data of the raw material from which it is split, and the measures to be obtained from the container, will be reflected therein. In certain cases, these means will have a closer tolerance to respect at the time of regulating the machine. During series production, a greater range of tolerance can be allowed at the same level.

An important criterion to respect in the preparation of the “Product Data Sheet”, is that the dimensions or values that appear in it, and that have to be monitored during the production by the line operators, or previously by the preparation mechanics, are easy to determine, without the need to use complex equipment that requires a certain dedication or a long time, since operators usually do not have it.

We will go into detail in the definition of a “Product Card”. For this we will use a specific case.

PRODUCT SHEET OF A SAUSED PACKAGING

The example that we are going to develop will be that of a very typical canned fish container: RO 170, that is to say it has a capacity of 170 cc, with a body diameter of 83 mm and a height of 37.5 mm. The value 83 of the diameter is nominal, since it really approaches 83.7 mm.

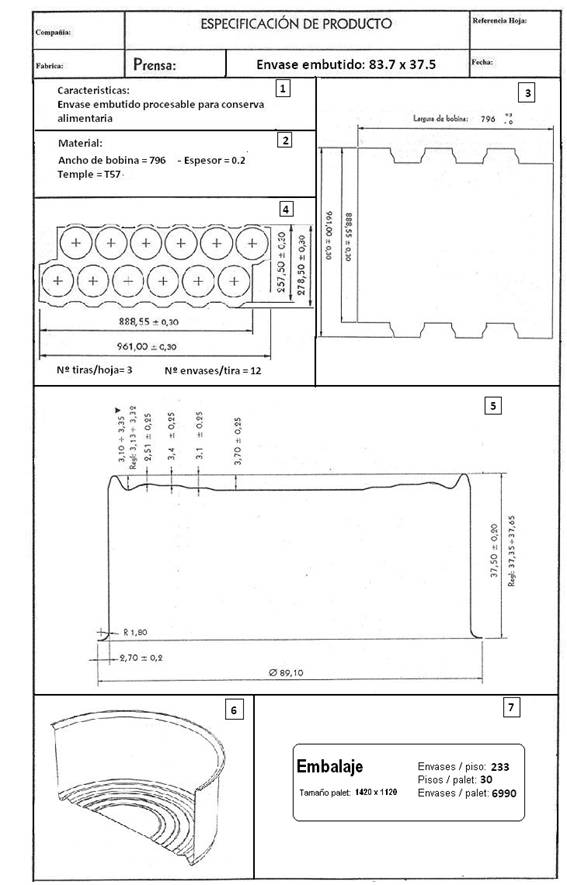

In the drawing no. 1, an overview of the “Product Data Sheet” of this container is presented. Then we will go into the detail of each one of the sections that compose it. For the moment, let’s stay with its general configuration. In a single document the basic data are reflected, to be taken into account in each of the steps, which are carried out throughout the process, such as: cutting the sheet from the reel, cutting into strips, drawing and packaging . In all cases these are values to be obtained on the elements obtained and therefore, although they are directly linked to the dimensions of the tools, they do not have to correspond exactly with them. No more complex data to determine, such as loading of varnishes, lubrication … tasks more typical of the Quality Control Department.

There are certain measures or values that are reflected twice, some to be used during the adjustment of the machine, and others that must be met during the manufacturing process. Those corresponding to the adjustment are marked specifically on the drawing. The measurements that in each step are considered critical are indicated by a triangle.

Figure no: Product datasheets RO 170

Let’s go into the detail of each of the operations.

The first boxes allow to reflect identifying data such as: Company, factory, reference number of the sheet, date …

The box marked with 1, defines the product to be manufactured and 2 the characteristics of the raw material, that is to say the rolled metal coil.

CUTTING THE METAL COIL

The first operation is to cut the sheet coil to the appropriate dimensions. In the example file, the corresponding box is marked with the number 3. To adjust the cut line to the appropriate measures, in this section you must indicate:

– Dimensions and thickness of the material sheet

– Tolerable tolerances. Those of the width of the sheet, coincide with those of the coil supplied by the steel industry.

To follow the quality of work in a line of cut of coils, we recommend to see the article:

Quality control in coil cutting lines

CUTTING THE LEAF

The packs of sheets, once varnished and / or lithographed, go to the production line, where the first operation is to cut the sheet into “scroladas” strips – in zig-zag -, provided that the line is equipped with a shear type “Scroll”. This operation may be done separately, or even in a circular shear in straight strips.

In any case it is necessary to know the detailed characteristics of the strip to be obtained. In our example they are reflected in box nº 4. In the same one the central strip is drawn, those of the ends can have a straight edge.

It can also happen that the press works with a whole sheet, in this case, this operation does not exist.

EMBUTITION

Regardless of whether the press is multipunzón or of simple tool, it is required to know those measures on which it is possible to act on the equipment. In the case of a stuffed container, these are reduced practically to the heights, as much of the container as those of the different moldings of the profile of the bottom of the same, the rest of them are determined by the tool, and it is not task of the section of Production act on it.

On the drawing no. 5 of the sheet the different heights are noted. It should be noted that the total height and depth profiles of the bottom profile have double value and tolerance, corresponding to the adjustment and production data respectively.

The depth level of the bottom profile is marked with a triangle, indicating that it is a critical measure. In this case, because the behavior of the background profile during the process is linked to its level of relief.

The operation of trimming the excess material, which defines the outer diameter of the flange of the container and the value of itself, can be a subsequent and independent operation, located in another press, or carried out in the same drawing operation if the tool of stuffing is double effect. In the example we have considered that it is the second case and its data appear incorporated in the drawing of the drawing operation.

ACCESSORIES

The product file can be completed, with a drawing of the container to be obtained, see box 6 and with information on its packaging, see box 7.

You can even include other data such as: cut-off value of the embossing die, lubrication to be used (type and load), etc

0 Comments