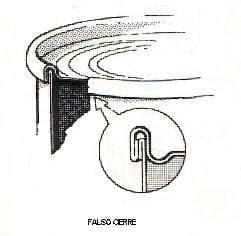

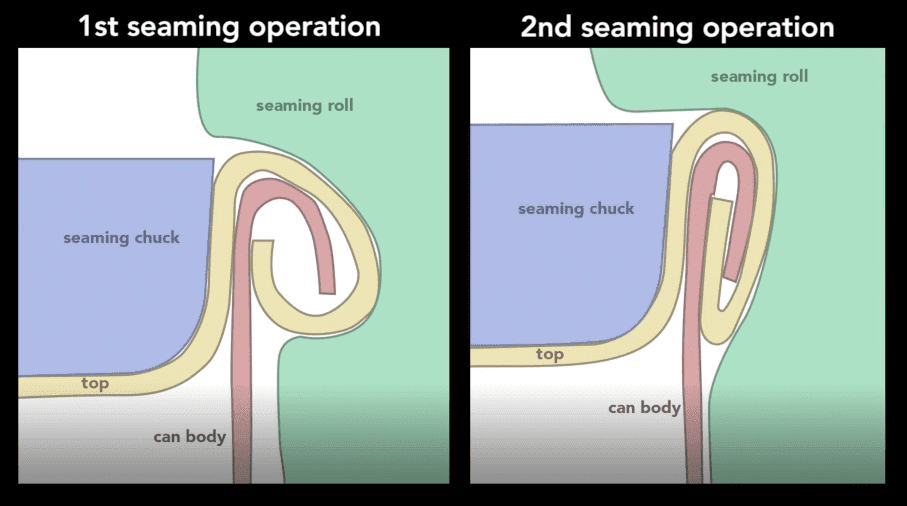

A false closure can be caused by several factors. To solve it, it is first necessary to identify the cause of the problem and then apply the appropriate solution. Here are some common causes and possible solutions:

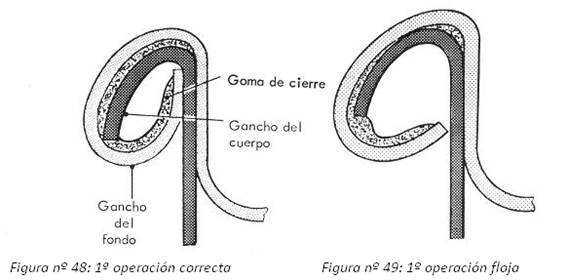

- Damaged, bruised or crushed body tab: Check the condition of the body tab and, if necessary, replace or repair the damaged part.

- Blinked” body flange: This can be caused by poor flange adjustment or poor condition of the flanging tooling. Adjust the tab setting and check the condition of the tooling to ensure that they are in good condition.

- Bottom flange curl defects: Inspect the bottom flange curl for bumps, marks or other defects. If necessary, replace or repair the affected part.

- Incorrect positioning of the bottom on the sealing mandrel: Make sure that the bottom is correctly positioned on the sealing mandrel before proceeding with the sealing process.

- Product or foreign matter deposited on the flange: Clean and remove any residue or foreign matter that may be present on the flange.

Remember that false closures can be difficult to detect and are always dangerous. It is important to inspect the bottom of the seal to identify and resolve any false seal problems.

0 Comments