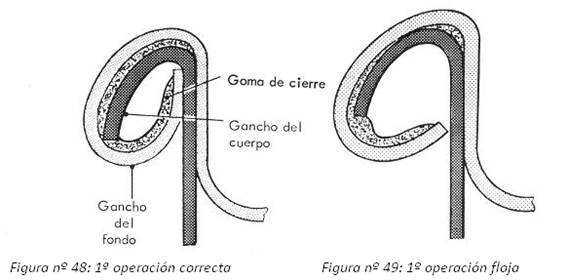

Wrinkles in the double seal of a can can indicate possible problems in the quality of the seal and, consequently, affect the integrity of the container and the preservation of the product inside. It is important to identify and analyze wrinkles to minimize the risk of seal defects. Here are some types of wrinkles and their associated risks:

- Large isolated wrinkle: If there is a large, isolated wrinkle in the bottom hook, this may indicate that the material has not been gathered evenly during the closing process. This may compromise the tightness of the seal and increase the risk of product contamination.

- V-shaped wrinkle: V-shaped wrinkles have a wave inversion. Normal wrinkles are slightly concave, while inverted “V” wrinkles are convex and therefore in relief on the surface of the bottom hook. These wrinkles can weaken the seal and increase the risk of leakage.

- Crease: A crease in the closure means a step in the bottom hook face, which can increase the risk of micro-leakage and compromise the tightness of the package.

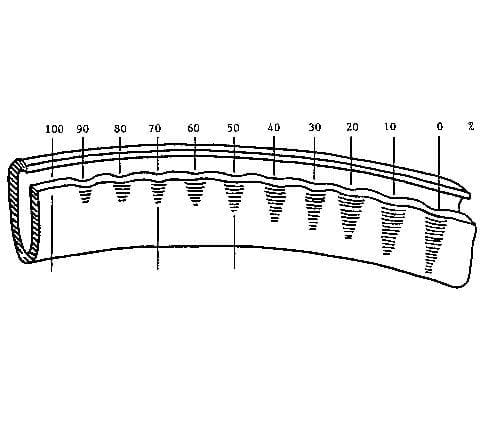

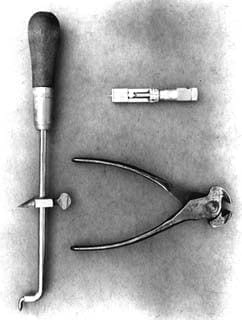

To control the risk of wrinkles in the double seal, it is important to carry out visual inspections and use appropriate measuring tools. The wrinkle percentage is defined as the percentage of the wrinkle size versus the total hook size. A maximum acceptable wrinkle rate of 30% is established.

In summary, to minimize the risk associated with wrinkles in double seaming, it is essential to carry out rigorous quality control and adjust the parameters of the seaming process as necessary.