On different occasions we have been asked the question: What are the advantages or disadvantages of using sausage packaging in relation to the classic “3 pieces”? Or also What is preferable to use 2-piece or 3-piece containers? The answer is not simple, because many considerations come into play, and can be approached from different perspectives:

– From the point of view of the container or user manufacturer.

– From the point of view of economy or quality.

– From its appearance – or presentation – or its manageability.

– From its simplicity or its complexity in its manufacture

And so we could add other different viewing angles. In this paper we will try to give some answers to these questions.

SCOPE

In the first place we must try to delimit the field of application to which we will circumscribe ourselves. The approaches can be very different. Of course, the field of application must be defined by the final destination of the container. In principle you can consider three major fields of use of packaging:

– Drinks : It is very clear that in this area, the type of container that mostly covers the market is the “2 pieces” with DWI technology. The use of packaging of another type is purely testimonial, therefore it is not appropriate to consider what kind of packaging is suitable, the market has already decided.

– Industrial : For its characteristics of very wide range of uses, formats, types of closures, accessories, etc. and also its consumption in small productions, it is a fact that the type of packaging that is required is the “3 pieces”, since its manufacturing lines at low speeds are versatile, simple and effective. Therefore, the discussion should not be considered here either.

– Food : It is in the containers for the classic food preserves of all kinds: vegetables, meat, fish …, where the question of defining in each case is the ideal packaging, because the market offers different solutions that can have advantages and disadvantages throughout the process, that is, from the design of the container to its final destruction. Therefore, this work will focus only on the packaging used in this field.

PACKAGING FOR FOOD APPLICATIONS

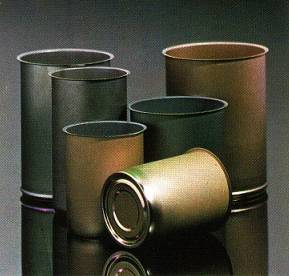

The basic types of containers that can be used to contain food, are really three:

1º.-The classic “3 pieces” in their different versions of welding of the lateral seam of the body, and endowed with easy opening or not covers.

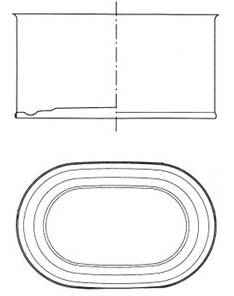

2º.- The “2 pieces” of simple technology, that is, those obtained by simple stuffing. In general they include all those whose height is less than half their diameter.

3º.- The “2 pieces” high, achieved by successive embossments, which require a more complex technology. They are called “DRD”.

We will not go into describing the manufacturing systems of each of them because they are not the subject of this work. On this website, there are different articles that deal with it, such as:

QUALITIES OF THE DIFFERENT TYPES OF CONTAINERS

We will try to list some of the qualities presented by these three groups of containers. We will list each of them, and determine what level these types of boats have. For this we will first of all on the side of the manufacturer of the same, and then on the side of packer or user. Another aspect is the interests of the consumer, which must prevail over those of the container manufacturer and also over the packer, but they largely coincide with those of both.

MAKER:

According to our point of view the qualities to consider, thinking as a manufacturer, are:

Use of alternative materials: Those that demand a simpler quality of the basic raw material – the metal – are the “3 pieces” containers, because in them the material suffers less deformations and efforts, but they have the limitation of not being able to use the electrically welded body – which is the usual technique -, very low tin coating materials (LTP), chromium plating (TFS) or aluminum, which is important. This does not happen with inlays, although they require a more specific base steel quality. Due to the above, we consider that in this section there is a certain advantage in embedded packaging for admitting a wider range of metals.

Ease in decorating design: “3 pieces” containers are lithographed in plan and complete sheets, using a conventional technique, so it is easier and cheaper. The “2 low pieces” use the same procedure, but the design of the lithography is complicated, since it is necessary to make a compensation of the deformations in the drawing, and also there are limited areas in which texts or images with lines can be placed straight. The complexity is even greater in the case of DRD, because it requires a packaging impression per container. In fact the printing on metal is used very little on this last type of boats, resorting mainly to the labeling in paper.

In summary, in this section, “3 pieces” containers have an advantage.

Total lithography of the surface: The types “3 pieces” need to reserve a zone without lithography for the lateral welding of the body. The other two types can be printed in their entirety, although the DRDs on the finished canister.

Quality level: Due to the manufacturing technique, the quality obtained in the embedded packaging is more uniform and presents fewer risks of parameters out of control.

Absence of leaks from the side seam: Due to the suppression of the side seam on the body in the inlays:

– The risk of leakage in the container or microbiological contamination of its contents due to micro leaks is reduced.

– The closing operation of the lid is facilitated by eliminating the double thickness in the seam area, which allows an increase in the working speed.

Absence of leaks in closures: In embedded packaging, by eliminating the closure of the bottom, the risk of leaks is reduced by 50% due to this concept, implying:

– Reduce the risk of microbiological contamination when the closure disappears.

– Simplify manufacturing by suppressing an operation

Recycling: The containers “3 pieces”, having to be manufactured in tinplate – at least the body – present advantages in the recycling. They can be separated by magnetic system and subsequently recovered tin. The aluminum sausages recycling is not so simple.

Technological Simplicity: The simplest way to manufacture a container is by the simple method of embedding, on the contrary the greater complexity supposes to resort to the embutido-reembutido (DRD), due to the high technology of the tooling and the equipment to be used. The means used to produce the “3 pieces” move in a very wide range of techniques, but in general they are not very convoluted.

Availability of equipment in the market: Due to the age of the market, there are many manufacturers of equipment for the technology of “3 pieces” and of the low sausages – presses -. There is a shortage, for DRD.

Economy in the cost of the investment: The most economical investment is always the necessary one for the low embossed containers, adequate presses and their tools are enough. On the contrary for DRD the equipment is very expensive, more if it includes the systems of varnishing and printing. The lines for “3p” containers vary a lot in price depending on their speeds and the origin of the machines, from the latter it is possible to get equipment in the second-hand market.

Flexibility of the facilities : The most flexible, without doubt are the lines for “3 pieces”. The facilities for low sausages and especially the DRD are usually very little reconvertible.

Incidence in the cost of the container : The best use of the basic raw material – metal – is usually achieved with embedded and DRD containers, by stretching they are suffered and facilitates the formation of their walls. The elimination of the side seam and the closure of the bottom is also a saving. This compensates for the possible increase in metal cutting, which is greater in the case of round containers.

We have reflected in a table the qualities detailed above, scoring them in each case, giving a value of 1 to 3, with the following criteria:

3 = High value quality

2 = Quality in average value

1 = Quality at low value

The concepts that in our opinion are most relevant have been reflected in bold. At the end, the scores are added with two criteria: all of them and only the most relevant ones.

As a conclusion for a boat manufacturer, it is seen that for a given format, assuming that it is feasible to do it by means of two different technologies, – bearing in mind that the one used for low packed sausages can not be compared with that of DRD , since one excludes the other -, we can summarize:

– Between “3 pieces” and low sausage: It is more interesting to use sausage containers.

– Between “3 pieces” and DRD: It is more interesting to use DRD, but the differences are smaller

Do not forget that there are packaging formats where it is not possible to apply the technique of drawing in either of the two forms, so the use of facilities “3 pieces” will always have a market.

PACKER

On the other hand, from the perspective of the packer the qualities to be considered are:

Manufacturers in the market: The packer should be that there are more manufacturers in the market better, because a greater number of manufacturers, the greater the competition in quality and price, ensuring better levels of performance. Under this point of view, the largest number of manufacturers are in the case of 3 pieces and 2 pieces low packages. There are few that supply the DRD packaging market

Range of available formats: The most extensive catalog of formats is presented by the field of “3 pieces”, there is a variety of sizes where you can choose the one that best suits the needs of the product to be packaged. The low sausages reduce their range due to their height limitation, and the DRDs for the minimum flexibility of their production facilities.

In relation to the sections : Total lithographed of its surface, Quality level, Absence of leaks by lateral seam, Absence of leaks in the closures and Recycling, we refer to what was said above, when we treated the matter from the point of view of the Container manufacturer . These advantages are coincident for both.

Opening comfort : A discomfort, presented by the low sausage containers, in relation to the other two fields, it is a certain difficulty to keep them well secured with one hand, while with the other we proceed to its opening. This is manifested especially if they are equipped with easy opening lid. The cause is its high discharge, which does not allow the hand to apprehend them firmly.

With the same criteria as in the case of “Manufacturer”, we present below for the “Envasador”, a summary table of rated qualities

The conclusion is that the three groups of containers are very even, with a very small difference to the low-embossed containers.

In summary, we see that as a whole, there is no clear situation that one type of packaging is preferable to the others, although there are factors where one obviously stands out from the others. Depending on the peculiarities of each one, each one must decide what type of packaging is best suited to their requirements.

Regarding the final consumer, it usually happens that he detects better the deficiencies of the package than its advantages, and while it does not cause problems, “priori” does not opt for any in particular, although it is influenced by the presentation of the same.

0 Comments