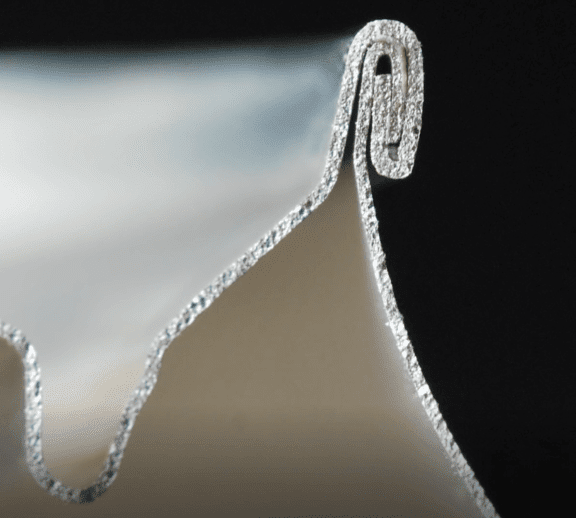

Sealing compound or sealant is a special material that coats the inside of the curl of a can lid. When the can is properly closed, the seam formed closes around the compound, creating a hermetically sealed joint that prevents pressure loss and blocks the entry of hazardous materials from the outside, such as pesticides, mold, pests and heavy metals.

Can sealing compounds are developed to provide consistent application performance and superior sealability in properly formed and compressed double seams. However, these compounds may not provide a watertight seal if contaminated with grease or oils prior to double sealing or if used on defective, loose or poorly formed double seams. An optimum volume of sealing compound should be applied to the end of the can so that it can fill the natural voids in the metal-to-metal joint that is the double seam.

The amount of sealing compound used depends on the type of compound, the diameter of the can, the sterilization method used and the style of container. Compound/product compatibility is crucial, as lack of compatibility can cause softening, staining and oozing, resulting in reduced sealing efficiency.

Water-based sealing compounds are dispersions of specially compounded rubbers in water which, when applied to the ends of cans, dried and properly sealed in the cans, provide an airtight seal. These compounds offer a volatile organic compound (VOC)-free option compared to solvent-based compounds. Proper handling of all sealants is necessary to ensure satisfactory coating and end sealing performance. Compounds should not be frozen or exposed to direct sunlight or stored near heaters, and should be kept in a temperature range of 5 to 35 °C (41 to 95 °F).

In double seam integrity, the absence of other materials in the sealing areas, such as product, excess solder or sealing compound and foreign material, is essential. In addition, the presence and proper placement of sealing compound is necessary to fill the main sealing area and prevent leakage.

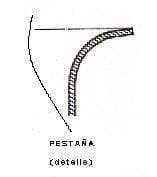

Proper mechanical overlap of the body flange and end crimp results in an overlap and compression of the interlocking flange and crimp form body and end hooks that are closely interlocked, keeping the sealing compound under compression to ensure a tight seal.

Can ends are supplied with a sealing compound in the end curl, which softens during the sterilization process and is a vital component in establishing an airtight seal. End inspections should be performed upon arrival to verify the presence of sealing compound.

In summary, the sealing compound is critical to ensure the integrity and tightness of the can seal, and its proper handling is crucial to the performance of the final seal.

If the Compound Sealant has the appearance of mold in some area, what implication does it have on the performance of the Aluminium Beverage CAN.