If you want to read “BARNICES .- Part 1” click here

PART 2:

| CHARACTERISTICS OF VARNISHES

The data shown in this table should be taken in general terms, since each coating has specific characteristics. |

||||||

| Type | Drying | Flexibility y membership |

Resistance to sulfidation |

Resistance chemistry |

Usage | Applications |

| Oleorresininsos “R”. | 205ºC/12′. | Good | Mala | Resistant to acids |

Varnishes interiors |

Acidic fruits Vegetables |

| Oleorresininsos “C”. | 205ºC/12′. | Good | Good | Does not resist to acids |

Varnishes interiors |

Rich foods in proteins |

| Phenolics | 200ºC/15′. | Mala | Very good | Good | Finished varnish B. interior |

Meat and fish |

| Epoxy-phenolics | 200ºC/15′. | Good | Regular | Good | B. interior B. hitch |

Rich foods in proteins |

| Epoxy-phenolics + Al | 200ºC/15′. | Good | Very good | Good | B. interior | Rich foods in proteins |

| Epoxy-phenolics + OZn | 200ºC/15′. | Good | Good | Not suitable for acids |

B. interior | Rich foods in proteins |

| Epoxy-amines | 195ºC/12′. | Good | Regular | Good | B. hitch B. exterior |

Decoration |

| Epoxy-ester | 180ºC/12′. | Good | Mala | Regular | B. finished B. exterior |

Decoration |

| Epoxy-modified | 190ºC/15 | Good | Good | Good | B. white inter B. hitch B. exterior |

Aggressive products Decoration |

| Vinyl | 180ºC/10′. | Very good | Mala | Regular | B. interior White enamel B. hitch |

Drinks Decoration |

| Acrylics | 190ºC/15′. | Very good | Very good pigmented |

Very good | White enamel B. finished |

Legumes Vegetables little pigment. Decoration |

| Polyester | 200ºC12′. | Variable | Regular | Good | B. white inter B. interior B. hitch White enamel |

Env. embut. and covers in 2 passes Drinks Decoration |

| Organosols | 195ºC/15′. | Very good | Good | Good | B. white inter B. interior |

Tapas easy opening Covers

Env, embut. |

FILM WEIGHT.

The dry film weight is the amount of dry extract remaining on the metal after the coating has been wet applied and baked. Measured in g/m2 (or mg/pg2 )

As a guideline, it may have the following values:

Interior systems:

– Varnishes in general Between 5 to 7 g/m2

– Varnishes + Al ” 6 to 9 “.

– Varnishes + OZn ” 7 to 10 “.

– Whites ” 9 to 15 “.

– Organosols ” 13 to 21 “.

External systems:

– Hooks Between 2 to 5 g/m2

– White enamels ” 14 to 17 “.

– Finishing varnishes ” 5 to 7 “.

VARNISH APPLICATION TECHNIQUES

There are three basic procedures for varnishes applied in liquid state:

- Application on one side of sheets by means of rollers

- Application on coils on both sides

- Spray application.

Roller blades

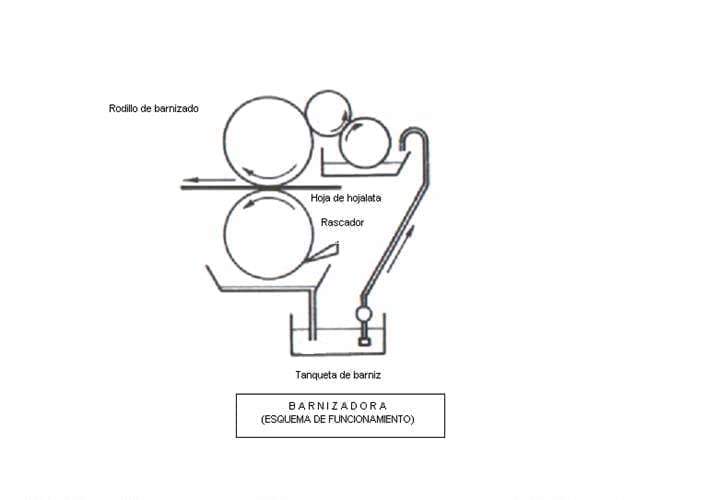

It is the oldest and most widespread varnishing process. Each sheet of metal is passed through a pair of rollers, one of which – elastic – is impregnated with the varnish to be applied. The material of this roller is gelatin or synthetic rubber, which cannot be attacked by solvents. With appropriate adjustments, the thickness of the applied coating can be controlled.

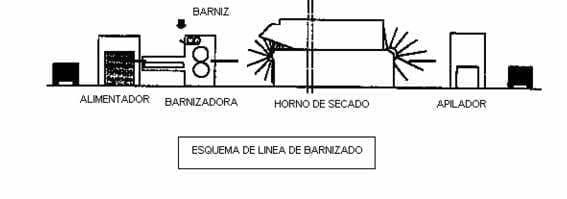

The set of devices that allow to feed from a package each of its sheets, move them and make them pass through the applicator system, is known on the market as a coating machine. A continuous oven is mounted next to it, which dries the varnish, eliminating its solvents and allowing the film of solid residues that remain adhered to the sheet to reach the right degree of polymerization and cross-linking for its protective function.

Baking conditions vary according to the type of resin used. In general, it can be around 200º C and a time of 12 minutes. The temperature will never be higher than 232º C – tin fusion – to avoid the harmful effects of tin remelting.

This varnishing technique is the most common in the metalworking industry, as it is very flexible and adapts to all varnish needs and to the different parts of the container. Thus, by making the appropriate “reserves” on the elastic roller, it is possible to coat bodies for three-piece containers, where the areas to be welded must be free of varnish, deep-drawn containers, lids, etc.

Coils

It is possible to varnish coils in a process similar to the previous one but in a continuous way. It is much more complex and has more limitations, as it is not possible to make varnish reserves. Its use is limited to covers and stuffed bodies in large runs.

Spraying

There are some container uses that due to the aggressiveness or delicacy of the product – for example: carbonated beverages – require that their inner surface be totally free of exposed metal – pores, scratches, abrasions, etc. – and the varnish – usually in several coats of different types – must be applied once the container is finished. In these cases, spray application is used, using a fixed or mobile spray gun while the container rotates at high speed. Subsequently, the drying process is similar to the first technique. This application is typical of DWI “two-piece” packages.

A similar way of spray painting can also be applied to cover the side seam area of “three-piece” container bodies. This area has been reserved for varnish to make welding possible and then needs to be protected by spray application and subsequent drying. This procedure was in force for quite some time but today it has been displaced by another system of powder coating application.

These powder coatings are of the thermoplastic or thermosetting type, applied by an electrostatic deposition technique on the surface to be protected and then subjected to heat to cause its fusion. They have the advantage of reducing the emission of solvents into the atmosphere since 100% of them are solids.

VARNISH PARAMETERS

The most important ones to control are the following:

Liquid varnish:

- Viscosity

- Specific weight

- Resin type

- Solvent

- Assignment or migration tests

Varnish applied dry:

- Film load or weight

- Curing control

- Adherence

- Porosity

- Autoclave resistance

- Scratch resistance

- Resistance to sulfidation.

The description of these tests would make this work excessively long. As they are common to all metal packaging coatings and in a way represent a separate chapter on metal packaging coatings, they will be dealt with in a separate topic.

0 Comments