After the sad case of botulism that occurred in the city of Andresito in Argentina, with some fatalities to regret, thermal validation studies in the production of canned food become relevant, since these evaluations irrefutably conclude whether the canning processing plant is performing an appropriate thermal treatment, whether pasteurized or sterilized, to eliminate any risk of Clostridium botulinum presence in the canned food produced, considering that this microorganism is the producer of the deadly botulinum toxin.

Any company processing food for direct human consumption that has a good Quality Management System (QMS) will implement a HACCP (Hazard Analysis Critical Control Point) plan in its plant, which defines at what stage of its production process there is a potential risk to food safety that affects public health and can generate a health alert. For this reason, canning plants, mainly those that process low-acid foods (LACF), such as meat, fish, seafood, asparagus, peas, beans, corn, figs, milk and others, with a final stabilized pH higher than 4.5, consider sterilization as a critical control point (CCP) in their HACCP and have to carry out thermal validation studies as evidence of their verification procedure, to be submitted to the health authorities of the country of origin or to external authorities, such as the Food and Drug Administration (FDA), European Food Safety Authority (EFSA), EU, UK, DIPOA, SENASA and others at a global level.

The studies are performed by a Thermal Process (TP) authority, which is a person or organization with a thorough knowledge of the requirements or demands for high temperature processing of foods packaged in hermetically sealed containers to make them safe for the consumer and who also has the appropriate equipment and expertise to make such process determinations.

The studies are mainly two, the one of temperature distribution in autoclaves or pasteurizers, which we will deal with in this article, and the one of heat penetration in cans, with the calculation of lethality or Fo in the packaged food, which we will deal with later.

The subject of thermal validation of canned food in metal containers is somewhat extensive, for this reason I have decided to present it in two parts, if there is any doubt about the subject, we can clarify it later through Mundolatas.

1. The Temperature Distribution Study

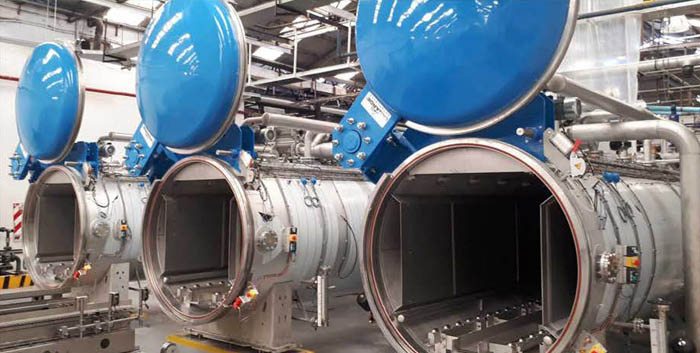

It is performed in conventional pasteurizers or autoclaves with direct steam, cascade, water spray, flooding, overpressure and others, in order to define, according to the design of the equipment as well as the heating medium, the operational procedures necessary to achieve temperature uniformity inside the autoclave from the stabilization time, Come Up Time (CUT), rise or venting, which is defined as the time that passes from the beginning of the heating or steam entry to the equipment, until the effective start time of the programmed thermal process begins to be measured, which is when the autoclave reaches the established temperature and is registered by the bulb of the official process thermometer installed in the equipment.

This initial heating stage inside the equipment, until the established sterilization temperature is reached, is part of the thermal process and should be recorded in the daily records or charts generated by the thermal recorders. These records should be filed by quality control as evidence of compliance with the operational procedures established by the PT authority in the temperature distribution study.

2. Preliminary Evaluation of Plant and Autoclave Standardization

A good standardization of the canning plant will consist of creating the appropriate conditions with infrastructure and equipment that guarantee a good supply of supplies to the autoclave bank, such as steam, air, water and electrical energy, sufficient and of good quality, so that this equipment achieves a correct temperature distribution in the sterilization process without deviations.

In the evaluation made by the PT authority, it shall consider in operation all the productive lines of the plant, the peak consumption of the supplies at maximum production capacity, the distribution of steam piping or layout with sectional areas, from the boiler room to the consumption points, the line pressures in psi (lb/inch.), the line pressures in psi (lb/inch.), and the pressure in psi (lb/inch.) of the steam piping.2) in the steam piping, mainly in the manifold that supplies steam to the autoclave bank. I personally recommend performing a thermodynamic balance, to define if the steam generation in the boiler room (lbs/H), versus the consumption of the peripheral plant equipment at maximum production, as well as the autoclaves and stoves, are in equilibrium.

The autoclave bank should also be evaluated as a group and individually before performing the temperature distribution studies, as this information or Retort Survey (RS) will be part of the final report with the results obtained. Ideally, retorts should have the same design or standardization, so that the study of one retort validates the rest. In the case of conventional direct steam pressure autoclaves, commonly used to sterilize cans, the Code of Federal Regulations, part 113 of the FDA or the recommendations of the National Food Processors Association – Bulletin 26L can be used as a reference, which define the venting provisions in this equipment. In addition, the equipment and instrumentation used in each autoclave should be recorded, as well as the systems or type of automatisms used for the control, maintenance and recording of the process temperature in each cycle or batch.

The information or RS of the autoclave bank and mainly the conventional direct steam with pressure should consider: a two-dimensional sketch of the installations, steam generation in BHP, number of autoclaves with their individual dimensions, capacity in baskets per autoclave, dimension of the main steam manifold or Header, dimension of the steam inlet to each equipment or Steam Inlet, dimension of the steam spreader or Steam Spreader, size and number of perforations in the steam spreader, venting system, size and type of valve that governs the venting, number of vents in each autoclave, number of bleeders, bottom drains to eliminate condensate, air line, water supply and other data considered by the PT authority.

3. Preparation of the Temperature Distribution Study

The temperature distribution study should be prepared considering all possible variables and in the most critical condition, such as the maximum number of retorts that start the process simultaneously or at the same time, the diameter of the piping that channels the simultaneous venting of the retorts, design and percentage of the free area of the cars, the stowage and configuration of the canned food load, percentage of the free area in case dividing sheets are used, the initial temperature of the coldest cans in case hot food filling is used, also consider the temperature of the coldest autoclave to carry out the study.

It should be taken into consideration that for conventional autoclaves that use pressurized steam as heating medium, the air must be removed from the autoclave before starting to count the effective process time, since air is a much less efficient heating medium than saturated steam, this operational procedure is known as air removal, purging or venting. Steam has a considerable amount of stored heat or energy, resulting from the conversion of water to steam in the boilers, whereas air does not have these calories and being cold interferes with the heating of the processed preserves.

4. Product and Packaging Selection for the Study

The temperature distribution study is carried out in the most critical condition, which is when the pasteurizer or autoclave is completely filled with product, with tubs, baskets or cars full of canned food. If the plant uses circular containers, the one with the smallest diameter should be chosen, and if rectangular containers are used, then the cans with the lowest height should be chosen. At this point it is necessary to take note of the number of cans placed in each basket or car, especially if dividing sheets are used.

If the plant intends to validate with the same study a wide range of the canned products it produces in various presentations, then cans can be filled with water or another product that is heated by convection and thus be able to perform several evaluation runs, without hindering the normal production process of the plant and without damaging food unnecessarily. The temperature distribution study should be performed at least twice in the same autoclave, considering the same critical factors.

5. Temperature Recorder Equipment and Thermocouples

It consists of a multichannel recorder potentiometer or a modified computer for data collection and must be connected to a properly grounded power source to avoid recording erroneous temperatures by the thermocouples. Currently there are also wireless data loggers that store the recorded temperatures on a chip that is then downloaded to a computer.

The copper-constant T-type thermocouples should be connected at one end to the recording equipment; if possible, they should be of a single body and of the appropriate length according to the dimensions of the autoclave where the study is to be carried out.

The thermocouples, sensors, probes and the time-temperature recording equipment must be calibrated before the test, all the sensors must be grouped inside the autoclave, near a calibrated standard thermometer, to verify if they adequately register the process temperature at which the test is going to be performed, this calibration must be performed once the venting, CUT or lift has been completed and the process temperature inside the sterilizer has stabilized. Each sensor must be identified with a particular channel number in the recorder and must correspond to the same number of the sensor placed inside the autoclave, this must be documented in the Location Record for subsequent analysis of the study.

6. Temperature Distribution Study

The personnel responsible for placing the probes inside the autoclave, between the cars and for data collection, must be supervised and directed by a PT authority, so that they apply the worst case criteria and can finally define the critical factors, which are parameters, ratios, measures or mandatory operational procedures (temperature/venting time, initial temperature, can size, total CUT, etc.), to achieve good temperature distribution inside the autoclave. Any non-compliance with a critical factor is defined by the FDA as a process deviation and for any sanitary accreditation such as: BRC, IFS, HSEQ, FSSC 22000, etc., as a critical non-conformity, since pasteurization or sterilization is a CCP.

The sensors for the study will be distributed among the cans, arranged in the cars of the autoclave completely full and at full length, their number will be such that all the baskets are evaluated. As a rule in horizontal and vertical retorts, the cold zone of an individual car is normally located along the center of the vertical line of the car, between the center and the bottom of the car. Additionally, at least 1 or 2 sensors should be located next to the bulb of the official process thermometer installed inside the equipment.

The location of the sensors is intended to determine the ability of the steam or heating medium to circulate between the containers, to remove the cold air trapped inside the retort and to stabilize the temperature of the programmed process. During the test, condensate should be prevented from circulating through the cables on the outside of the autoclave and distorting the temperature readings or damaging the electronic equipment. Time and temperature data are taken at intervals of one minute or less and up to 20 minutes after reaching the programmed process temperature.

7. Presentation of the Study with Data Analysis

The temperature distribution study is presented in a written report where the following must be considered: the company name and location of the processing plant, date of the test, description of the sterilizer or pasteurizer including the RS, type and conditions of the thermal process, minimum pressure in psi of the main steam header or manifold in the autoclave bank, the number of autoclaves that start the process simultaneously, size and type of container, product processed, graph with the location of the numbered probes, report with the temperatures recorded in each numbered probe, graph with the temperatures recorded in each numbered probe, hourly record of the operational procedures performed, time of entry of the temperature in each probe, time of entry of the temperature in each probe, time of entry of the temperature in each probe, time of entry of the temperature in each probe, report with the temperatures recorded in each probe, graphs with the temperatures recorded in each numbered probe, hourly record of the operational procedures performed, steam inlet time, time and temperature of drain and vent closures, total times and temperatures reached in the CUT, time and temperature to start the programmed thermal process, other critical factors considered by the PT authority who will sign at the end of the written report.

A guideline that has been used for many years indicates that temperature distribution data is acceptable if the temperature difference of any probe or thermocouple with respect to the official thermometer that records the process temperature inside the autoclave is less than 1.66 °C (3 °F) one minute after the end of the venting, lifting or Come Up Time (CUT) and is less than 0.55 °C (1 °F) three minutes later.

Personally, I consider that the guideline described above should be mandatory to define a good temperature distribution in pasteurizers and autoclaves that process canned foods. To look for cold zones in an equipment used to obtain commercial sterility is erroneous from the perspective of food safety; the previous evaluation of the standardization of the plant and autoclaves, which is carried out before the study, should rule out any possibility of finding cold zones in the heating medium.

The temperature distribution study is the most important of the two studies performed for the validation of thermal processes, since it ensures that all thermally processed cans will reach the calculated microbiological lethality regardless of their location in the heating medium.

0 Comments