INTRODUCTION

Rulina: It is the part of the seamer that performs the operation of deforming the metal, to configure the hooks of the lid and body and the link between them, resulting in the closure. There are two types, first operation, which forms the hooks and binds them together, and second operation, which crushes them together. It is also known by other names such as: trolleys, locking wheels, locking wheels, locking rollers…

Rulina 1st operation: As we have said, it is the one that constitutes the hooks of the clasp. Its function is more important than the 2nd operation, and its proper definition to achieve a good closing is essential.

There are many types on the market and their design can vary between them, although it is always linked to the type of closure you want to make and the characteristics of the materials used in the manufacture of the container.

The critical area of the roller is the groove that acts on the flange of the cover, rolling it over the flange of the body, thus generating the shape of the hooks that join the two. This area is called the roller profile and usually has a curved contour, consisting of several arcs of different radii.

This work is only intended to give some guidelines on the dimensioning of the profile of the 1st operation rollers, depending on the type of seal used. Other considerations such as the material to be used in its construction, mechanical characteristics, adjustment of the same in the seaming machine, etc. are treated in other works published on this website.

DESIGN OF THE PROFILE OF A ROLLER 1ST OPERATION

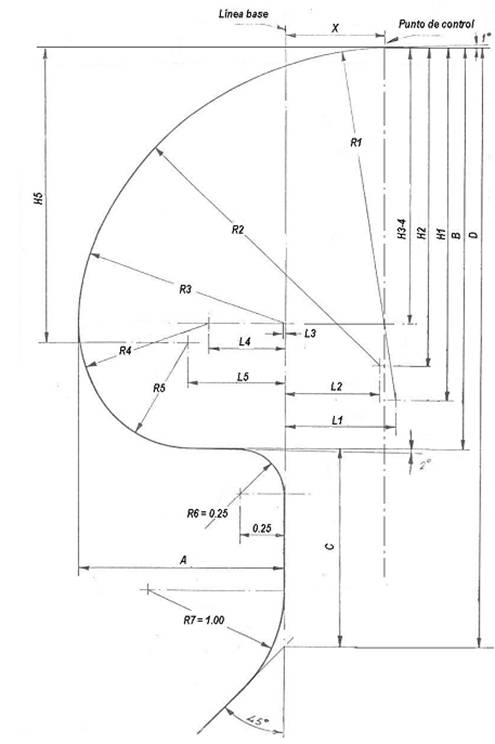

The upper part of this profile begins with a slightly inclined plane, approximately 1° of slope, followed by a large radius arc that connects with other arcs that progressively decrease in radius. The number of spokes can vary from a maximum of 5 to a minimum of 3, although 3 is the most common. Finally the profile ends in another inclined plane with a slope angle between 1st and 2nd. The profile is finished off with a more or less pronounced lower bead, depending on whether the container is notched or not, or on the type of closure. See figure nº 1

Figure no. 1: Generic profile of a 1st operation roller

Bearing in mind this drawing, it is worth highlighting the following as important points of the profile of a 1st operation roller:

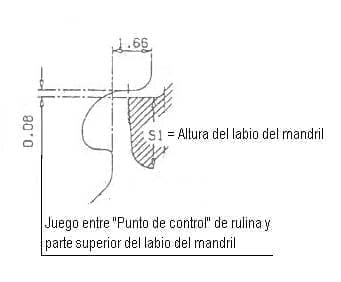

Control point: It is where the upper inclined plane ends and the entrance arc of greater radius begins. The vertical axis that passes through it is taken as a reference to delimit the different heights of the profile. From this point the roller is adjusted in height in relation to the lip of the locking mandrel. The clearance that must exist between this point and the top of the mandrel lip is 0.08 mm. See figure nº 2

Base line: This is the vertical line determined by the front face of the lower bead of the roller. Defines the depth of the profile throat. It is taken as a reference to delimit the measures of depth of this.

Radii: In drawing nº 1 a profile of five radii has been reflected, which is the maximum used in this type of parts. Of these, the most decisive are the first (R1), the largest value, which initiates the bending of the flange of the lid, and the last (R5), the smallest, which rolls up the end of the flange and forms the lid hook, the fundamental element of the closure.

Measurements: There are a few averages that can remain constant whatever the profile of the roller, these are the upper and lower angles and the heel radii. The rest varies as we have already said with the type of closure, which in turn is linked to the dimensions of the flange of the lid and the flange of the body, as well as the characteristics of the materials used in the container. Each company develops the ideal profiles to use in each case, maintaining a certain discretion in their dissemination. This gives rise to a multitude of solutions. We have selected in the following table the measures that experience has shown to be good in each case, although we insist that there are many other alternatives.

| ROLL DIMENSIONS FOR 1ST CLOSING OPERATION | |||||||||||||||||

| TYPE CLOSING |

A | B | C | X | R1 | H1 | L1 | R2 | H2 | L2 | R3 | H3-4 | R4 | L4 | R5 | H5 | L5 |

| OIII | 0,87 | 1,98 | 0,72 | 0,68 | 1,58 | 1,38 | 0,68 | 0 | 0 | 0 | 0,97 | 1,38 | 0 | 0 | 0,51 | 1,47 | 1,04 |

| OII | 1,21 | 2,17 | 0,73 | 0,68 | 1,73 | 1,73 | 0,47 | 0 | 0 | 0 | 1,06 | 1,51 | 0 | 0 | 0,55 | 1,62 | 0,65 |

| OI | 1,32 | 2,36 | 1,39 | 0,68 | 1,87 | 1,87 | 0,52 | 0 | 0 | 0 | 1,15 | 1,64 | 0 | 0 | 0,6 | 1,76 | 0,7 |

| I | 1,39 | 2,5 | 1,4 | 0,56 | 2,08 | 2,08 | 0,64 | 0 | 0 | 0 | 1,3 | 1,8 | 0 | 0 | 0,61 | 1,77 | 1,33 |

| II | 1,42 | 2,54 | 1,41 | 0,68 | 2,02 | 2,02 | 0,56 | 0 | 0 | 0 | 1,24 | 1,77 | 0 | 0 | 0,65 | 1,89 | 0,76 |

| III | 14,5 | 2,72 | 1,48 | 0,68 | 2,17 | 2,17 | 0,68 | 0 | 0 | 0 | 1,33 | 1,84* | 0 | 0 | 0,69 | 2,03 | 0,74* |

The following comments should be made on this table:

– Although a five-spoke profile is shown in drawing no. 1, only three-spoke profiles are shown in the table, which are the most commonly used. Therefore the values of R2 and R4 with the coordinates of their centres (H2, L2, H4 and L4) do not exist in these dimensioned examples.

– All measurements are rounded to the hundredth of a millimetre. Therefore, slight errors may occur in an exact geometrical drawing.

– The dimensions marked with an asterisk (*) are approximate.

– On the drawing there are two dimensions that do not appear in the table and that are determined from others. These are:

or D = B + C

o L3 = A – R3

– No tolerances are given. These should be as few as possible.

The practical results of rollers with these profiles depend not only on their geometrical configuration, but also on the quality of the materials used in their construction, the surface finish, machine adjustment, design of the closing head, etc.

Dear Sir,

My name is Mehedi Hasan From Bangladesh.

I need Seaming Roller 1st operation.please help me.

Hi Sir/ Madam,

Could you please help me quotes for below item:

part for seamer used lid B64

1 Seamer roll 1st (TICN-CVD) B64 6 pcs

2 Seamer roll 2nd (TICN-CVD) B64 6 pcs

3 chuck 200 (TICN-CVD) B64 6 pcs

part for seamer used lid CDL 200

1 Seamer roll 1st (TICN-CVD) CDL 200 6 pcs

2 Seamer roll 2nd (TICN-CVD) CDL 200 6 pcs

3 chuck 200 (TICN-CVD) CDL 200 6 pcs

Looking forward for you quotation.

Many thanks.