For the use of easy-to-open ends it is necessary to take a number of precautions, which are usually not necessary for the use of standard ends. Precautions must be taken, in particular, as regards their particularities in terms of physical and chemical resistance, since, because of the particular characteristics of the same, they must be extreme at all stages of the packaging process.

.

Easy – opening ends closed.

he easy-to-open ends must be closed with a special chuck, other than the one used for nor- mal ends, as the weakened area for opening is susceptible to cracking the chucks used do not fit perfectly in shape and dimensions. It is important that the chuck does not touch the ring, at its entrance into the end, because, if it hits this, and especially the tip area, it can initiate the opening of the end caused a lack of watertightness in the can.

Because the ring highlights the panelling of the end, the seal ejector should not over-hit the end, as it may deform the ring or deflect it from its position, subsequently making it difficult to open the end. In extreme cases, the incision may break, because of excess pressure on the ring or panelling.

On the other hand, the dimensions of the chucks must strictly conform to the recommendations

of the drawings that accompany the manufacturer’s specifications, since otherwise they may cause a bad clo- sure, or the breakage of the incision of the end, causing leakage in the cans, which may appear during the closure of the end or after the sterilization process.

NEOE chucks usually have a 4° angle. On the easy-to- open ends they have 2 angles, one of 4° and one of 8° reaching up to 12° in the deepest ends of countersink depth, such as the ends of aluminium beverage. The 4th must have at least the seaming height obtained since the height of 4° is where the seaming roll works. The rest of the grades is just to fit the end and obtain a stable double seam.

Transport and handling of packaging.

Once the end is closed on the can, shocks should be avoided on the different parts of the ends that are easy to open, as they may cause break- age and loss of watertightness, causing the

product to come out before or during sterilization. Thus, strong blows on the closure of the end easily open- ing, can cause breakage of the incision in the damaged area. Similarly, blows with other cans

on the panelling or the ring of the end, could start opening the end anywhere in the weak- ened area.

During the transport of closed cans, through air conveyors and/or conveyor belts, caution should be taken that there are no elements that can hook the rings of the ends, which could cause the cap to break or even open

the end.

This point is also applicable in the sterilization system, where they can lock the end rings lifted by the internal pressure of the product, diverting or prematurely open- ing the can.

After closing the cans, it is advisable to wash effectively with hot water, in order to remove all traces of packaged product and cover liquid, which may be retained in the end and body of the can. Otherwise, we would contam- inate the sterilization water, which could lead to chang- es in the chemical characteristics of the water and its conductivity, with danger of galvanic battery formation, which would result in corrosion phenomena in the cans and ends, or external stains of the cans.

Treatment during sterilizatione.

The easy-to-open end has two characteristics that cause special precautions to be taken during the packaging sterilization process. On the one hand, it has the incision, in which the base steel appears in the open, which has subsequently been re-covered. On the other hand, the ring, which, by its configuration, cannot be properly re-covered, so, for its protection, a galvanized material is used, which protects the base steel from oxidation.

In order to properly process the ends, and that they do not present oxidation problems after sterilization, the following aspects should be taken into account:

Whenever possible, cans should be sterilized with ends that are easy to open downwards, so that they do not accumulate water during sterilization.

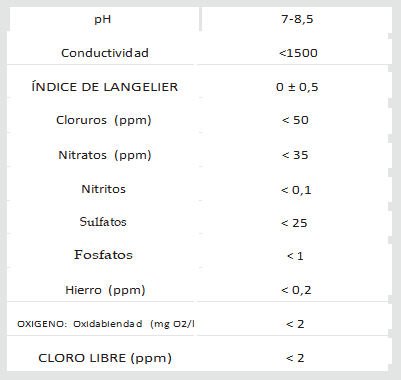

The water used must have characteristics of drinking water, since it must have a saline con- tent that does not provide a conductivity greater than 2000 s, in order to prevent the formation of galvanic batteries between the ring material and that of the end, and maintain a controlled composition according to the following requirements:

After sterilization, packaging, and in particular easy-to-open ends, should be completely dry, as due to their design characteristics (great- er bucket depth, ring, etc.) they tend to retain more water than a normal end, which can cause oxidation in the incision or ring, as hygroscopic saline remains remain after evaporation of retained water.

Storage.

The storage conditions for easy-to-open end cans do not require any treatment other than that necessary for the rest of the packaging. We must highlight, the need that in cans stored directly in pallets and without protection of boxes or retractable, the ends of easy opening must be positioned downwards, in order to prevent possible condensations of moisture and environmental dust from being deposited on

the ends, whose cleaning, if necessary, is more

difficult and also with a greater risk of oxidations

than the rest of the normal ends.

As a general rule, we should also take into account that in cases where pallets or packaged cans are retracted, before carrying out this operation, the cans must be cold (at room temperature) and completely dry, so as not to create corrosive atmospheres within the pallet or boxes, which in the

face of temperature differences can cause condensations and subsequent oxidations.

Finally, in necked cans, appropriately study the stacking and placement of the cans, so that the weight is not discharged incorrectly on the rings or weakening areas of the ends, which could cause breakage of the ends with the consequent output of the product and oxidation of the rest of the cans.

JOSÉ FCO. PÉREZ GÓMEZ

Asesor de Mundolatas

Mundolatas Advisor

0 Comments