The metal industry uses covers or funds with different types of profiles. In this article an explanation of the use of the most frequent ones is given as well as the selection criteria of the same ones.

INTRODUCTION

It is enough to take a walk through a supermarket with an observer spirit, to realize the variety of forms presented by the bottoms of the containers that are stacked on the shelves. They are flat or almost flat, or with a considerable amount of concentric moldings. We may have a question. What is the purpose of these moldings? Of course, they are not made by mere whim of the manufacturer.

Although in some isolated cases they can only have a decorative purpose, in the majority they have a specific function that results in improvements in the physical properties – we could say mechanical – of the containers. Therefore, when it comes to defining a container, one of the decisions that must be taken is to determine the profile of the appropriate covers / funds, where appropriate.

The profiles of the lid and bottom of a container have the important task of allowing it to adapt adequately to the conditions of pressure or internal vacuum, which it supports throughout its different stages of use (filling, sterilization, storage … )

COMPONENTS OF A PROFILE

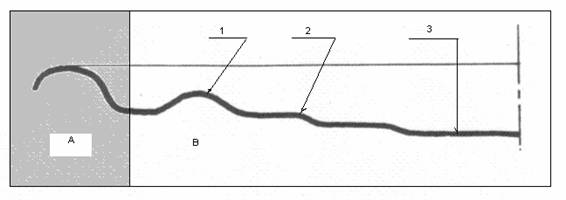

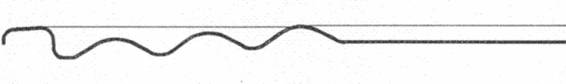

Before entering the analysis of the different profiles that can be used, we begin by defining the different elements that make up a profile. Figure 1 shows marked the typical elements that determine it.

Figure nº 1

A fund consists of two main parts:

A.- Ala . It is the area that will be incorporated at the closing. It is not the object of this work

B.- Profile . Area in which we will focus our attention.

Within the profile you can find:

1.- Expansion rings , also called reeds. They have a semitoroidal geometric shape. Its basic function is to give elasticity to the bottom. In other words, they perform a “sprung” effect in the presence of an important pressure difference between the inside and the outside of the container. This materializes in a deformation of the ring, tilting it on its outer edge, in or out. When there are several rings in a row, their effect is concatenated. In short, they are elements designed to easily deform before an external action.

2.- Gradients – or steps -, in the form of steps. Its destiny is to increase the mechanical resistance of the profile. In other words, it improves its resistance to deformation in the face of internal or external forces. To increase it, several can also be presented continuously. In short, its purpose is to remain unaltered before an external action.

3.- Central panel . It is the internal part of the profile, where usually no rings or gradients are placed, that is, it completes the surface of the bottom that has not been occupied by them. It can be flat or curved with a very large radius. It is usually intended for the placement of prints or printed with codes or legal texts, such as the expiration date of the product, or the country of origin of the conserve.

TYPES OF PROFILES

The shape of the profile is always linked to the use of the container, both from the point of view of the content and the industrial process of its filling.

1º.-Attending exclusively to its geometric shape, we could initially classify the profiles into two groups:

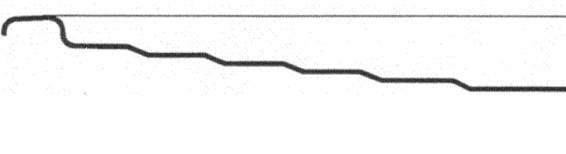

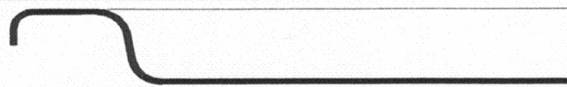

a.- Indeformable : They are constituted by a series of gradients, in the form of a staircase. See figure No. 2. They are very rigid. They have a high resistance to internal pressure or vacuum, with no visible deformation in the background. Because of their greater depth, with the same packing height, they reduce their capacity in relation to other types.

Figure nº 2

They present the disadvantage that in case of withstanding a pressure – or a vacuum – above their limit of resistance to deformation, they deform permanently forming peaks, which makes the package unpresentable.

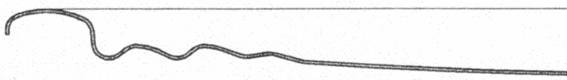

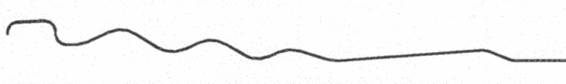

b.- Deformable : They present several expansion rings. See figure No. 3. They are elastic. When they bear an internal pressure, they soon deform to the outside, rising up flexibly. Thus they increase the volume slightly.

Figure nº 3

On the contrary, if the container has a certain degree of vacuum inside, the profile shrinks, reducing its capacity.

These deformations disappear when the pressure or vacuum is reduced, and although they remain residually, they do not look bad on the container, as they go unnoticed.

The greater or lesser capacity of elastic deformation is achieved:

– Increasing or decreasing the number of rings.

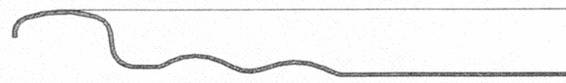

– Depending on the shape of the ring. For example, in the case of rings, the bottom of figure 3 is more deformable than that of figure 4, exclusively by the shape of the rings. In the first case, the reeds have an asymmetric configuration – formed with several different radii – and in the second symmetric – a single radius -.

Figure 4

In general, there are no deformable profiles or pure deformable, because always deformable are also slightly undeformable and vice versa.

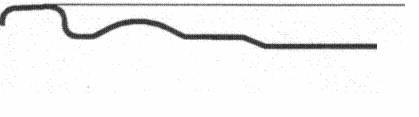

The most frequent case is to combine rings and gradients in the same profile, which gives rise to a mixed profile, which adapts well to the different situations of the container. See figure 5

Figure nº 5

2º.- Depending on its use, different types of profiles are used. A first classification, according to this criterion, would be:

a.- For products that will not be subjected to a sterilization process. For example industrial products (solvents, paints, oils) or for human consumption (vegetable oils, syrups …). For these uses, the cans are not subjected to strong changes in temperature and pressure. In this case the use of non-deformable profiles or even backgrounds with totally flat profile is adequate. See figure 6

Figure nº 6

b.- For processed foods: The choice of profile will depend on two factors: 1) properties of the product to be contained and 2) characteristics of the process

There are products that have a high coefficient of expansion when heated. Therefore, they increase in volume when subjected to high temperatures during the process. On the other hand, as is well known, it is not convenient to leave an excessive space in the head – empty space in the upper part of the container after filling -, it turns out that it is the lid and the bottom that must deform to temporarily increase the capacity of the container and thus absorb the increase in volume. It is clear that in this case it is necessary to use profiles as deformable as possible. A typical example is the packaging of animal feed or foigras. See figure no. 7 where asymmetric junctions of different sizes are combined with a wide width gradient that also provides elasticity.

Figure nº 7

Fish packed in oil – tuna – do not have this problem, because its expansion is small, but in this case the consumption of oil becomes a concept to be taken into account. For this reason, more non-deformable profiles are used, mixed type, which reduce the oil consumption by decreasing its volume, always within the tolerances established by the capacity legislation. See figure nº 8

Figure nº 8

Thus we could go considering each type of food, and depending on their properties, determine the profile. In practice, this is not done. Each manufacturer has a few profiles of different types, well experienced, that allow you to cover all your needs.

The parameters of the process also affect the choice of the type of profile. It is not the same to perform the same in an open autoclave than in a closed one with a good pressure control system. To equal product, in the first case the mechanical conditions of the funds must be much higher than the second. This means that they have to be very deformable.

It is very common to generate an internal vacuum by different means (hot filling, use of vapora, etc.). This vacuum manifests when the container has finished the process and goes to warehouse. The greater this vacuum, the more flexible the profile must be to adapt to it, thus avoiding the presence of peaks in the panel.

c.- Sometimes the choice of a profile may be alien to the product and the process. Simply that it is intended to increase or decrease the net volume of a container, without changing its height. As already mentioned, at equal height, an indeformable profile reduces the capacity, and a deformable one can increase it. For example, the deformable profile of figure 9, which in its central panel reaches the level of the closure, is a typical case of the latter. This type of background is used in brass for canned vegetables.

Figure nº 9

The easy-open covers have a flat central panel, with some smooth gradient – shallow. Therefore, we could frame them within the non-deformable type, and therefore with the risk of peaks appearing in the autoclave. This form is imposed by the constructive needs of the lid itself.

The containers that use this type of caps, which today are the majority, use funds with a type of profile depending on the use of the container. If, for example, it were required to use deformable, it would result in an imbalance in the performance of the lid in relation to the bottom. Which entails the need to use means for the process – autoclaves – of higher quality control.

0 Comments