The author tells about his experience in implementing a Preventive Maintenance and Repair Program – (Preventive Maintenance and Repair) – original of CCCo. (Continental Can Company – USA) for the first time in Spain in a metal packaging factory.

This Program was specifically developed for its Plates, for this reason it has differences with various Programs that are currently well known for the extensive documentation existing in the industry on MPT Total Preventative Maintenance, MP and R. (Preventive Maintenance and Repair)

Author: Juan M. Sancho Moronta.

A LITTLE HISTORY

1.- For more than 35 years – in particular since 1962 – in the different Carnaud Packaging Plants in Spain, I have been involved in installations, services, equipment, commissioning, and maintenance.

Generally the Maintenance was the function ignored by the Management, seeing it as a necessary evil. In relation to the economic situation of the Plant, the Maintenance Department suffered cuts in labor as well as in the purchase of materials. It should also be considered that at this time there was no program to justify the costs of the procedures and the old practices on “maintenance for breakdowns” or “annual maintenance”, highly expensive and difficult to justify and profitability.

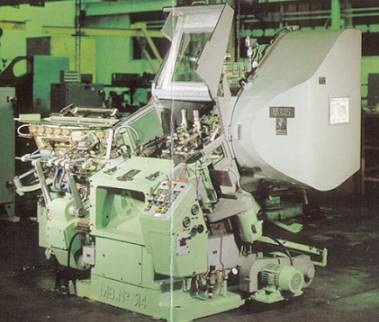

2.- In 1967, line 5 was installed in the Valencia Plant, designed for the manufacture of beer containers, format 211×413, three pieces, welded tin seam / lead 2/98%. The equipment was supplied by Metal Box (England), and its technical help was also available.

The manufacture of containers for beer began successfully. Later it was thought about the market of carbonated drinks. After several attempts to manufacture containers with standard quality for the Coca Cola company, and not having definitive success, the decision was made to take another route. We were in the year 1970, at this time there was no knowledge of the Programs of MP and R. of CC Co. We did not know the necessary changes, both philosophical and technical, to implement a TPM adapted to our work as packaging manufacturers. Neither our parent companies Carnaud (France) and Metal Box (UK) had it operational.

3.- In 1974, the Technical Management of the Company located in Madrid, headed by Tomas Somohano, obtained – through contacts with the “White Cap” Division of CCCo. and the “Techical Center” in Chicago (Mr. Stancik) – the authorization for the purchase and delivery of the equipment that guarantees the manufacture of containers, with Coca Cola quality, as well as the adequate training in “MPand Repeir”.

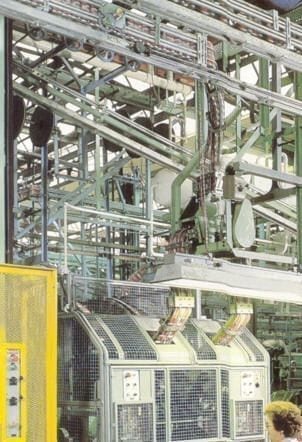

4.- At the beginning of 1975 the Technical Direction through Mr. Somohano proposes me to travel to Continental for training, training and reception of the equipment under the MP and R Program that CCC had in operation since 1970, in its Plants.

The training included: Receipt of the equipment and knowledge of all the complete applications of the TPM for the correct operation in the manufacture of beverage containers of measures 209 / 211X413, notched three pieces, side welding (2/98%), tin plate and lid type “easy opening”, the latter made with tools developed by “Dayton Reliable Tool” USA.

5.- I returned at the end of summer 1975 with the suitcase full of changes. The same, without realizing it had expanded my philosophical, technical, and practical knowledge originated by the training received in TPM

I was eager to develop the pilot project on the equipment implanted in a new line – the nº 7 -, which would be the one destined for this purpose and obtain the “Coca Cola” quality, which I never doubted could be achieved.

6.- With the approval of the Factory Management (Mr. Suárez Pumariega), several meetings were organized with Production (Mr. Billy and Mr. Bouchard, moved to this factory in technical commission and from Carnaud- France, as well as Mr. Marzal ).

During the presentation of the Program M. P and R. the reactions were diverse, because the changes required as a necessary requirement to carry out the Program, were not firmly supported, and the training of the pilot teams was paralyzed.

7.- While waiting for the arrival of the equipment coming from CCCo., I had enough time to develop the specific documentation for the practical training on the application. The formation of the groups included:

MP and Repair .

– Line 7, beverage container 209 / 211×413, v = 450 cpm

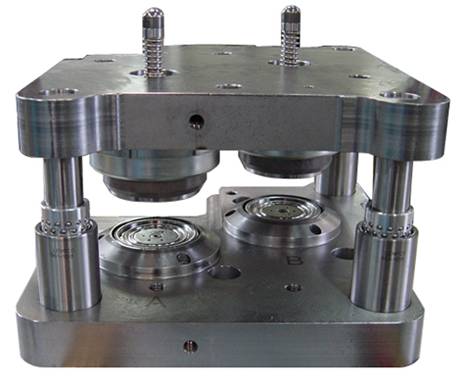

– Press funds, tooling diameter 209.

– Lithography, interior varnish of bodies and backgrounds.

– Mechanical Workshop, tooling and overhaul

– Electrical Workshop, programmable automata.

– Purchases and spare parts warehouse.

The easy opening lid would be produced in the Vigo factory, with the MP and Repair program guidelines.

8.- Project Support.

An important factor that was delaying its development in the Plant, came from the lack of support from the Management – the Director was in the process of retirement -, which he delegated to Mr. Billy and Marzal. I think that for reasons of distrust and ignorance.

9.- The machines arrived, the equipment was installed with precise alignment and precision leveling instructions, being the first time to use this procedure. At that time, we already had a new Director -Sr. Hernandez- more willing and interested in giving a boost to the project. Likewise Messrs. Billy and Bouchard returned to France and Mr. Marzal moved to Fabrica 1 Linares.

With these changes the Director assumed the Production Management and the one that tells this story, was as Factory Manager.

10.- 1978. Back to start with the implementation of the MP and R. The pilot groups are formed in the different departments for the project:

Program

First Phase = COMMITMENT. Time: 6 months.

Mentalization, Education.

Second Phase = PRACTICES. Time: 6 to 12 months

Equipment, MP and “Check List”.

Third Phase = RESULTS. Time: 12 months

Adapt load time, Results.

Fourth Phase = CONSOLIDATION. Time: All of operation

At that time we did not have a simple and recognized method for evaluating the improvement of results such as the application of (OEE) Overall Equipmen- tive Effectiveness:

% Equipment availability x% Performance x% Quality = 85% or more.

11.- Development of Phases:

Phase No. 1 Commitment .

MP commissioning for mechanics and line operators.

They were placed on the machines, cards with simple instructions such as:

- Daily cleaning

- Inspection of key points (no more than 5 points).

- Basic lubrication

- Small adjustments

- “Report” of failures that require repair.

These inspections are daily for the LMXJV days

(Between 5 and max 10 checkpoints per day)

(Between 2 or 3 checkpoints per week)

Phase No. 2 Practices .

They are made according to the program of taking checks for each machine (“Check List”), which were made starting from the original CCC for the same machines or similar.

Annual check-taking program.

Frequency and times for each machine: (example)

Machine Frequency No.inspec./year

(Inspection hours) (Total hours / year)

Bodymaker 1000 hours or 20 million / env. 3 (8 h.) (24 h.)

Bodyseamer 1000 hours or 20 million / env. 3

(3 h.) (9 h. )

Completed all the equipment, with these totals the annual budget of inspections (“check list”) is established

These inspections are carried out – with the special tools and training taken – by the staff of:

- a) Line mechanics – if they need help, they rely on:

- b) Mechanical Workshop Mechanics

Since the two groups are trained for this job.

Phase No. 3 Results .

Adapt the load time of the line, reducing the stopping times by:

- Small breakdowns

- Mismatches in equipment or tools

- Defects detected in mp

- Defects outlined in the “check lists” (these are usually the most severe)

For these interventions, the estimated time of the line stop must be requested from Programming.

T. Mechanic will have the mechanics and materials ready for the planned work. Whenever possible, it will require the assistance of the line mechanic or the operator. Once the work is finished, it will be delivered to the person in charge of the department, providing a copy of the “check lists”.

Phase No. 4. Consolidation .

During the years 1979, 80 and 81, line 7 of Valencia gave the greatest satisfaction to the Management, Controls and Operators. It surpassed the homologation for Coca Cola bottlings that was a mandatory requirement to be the supplier of this client. The generous delivery of the mechanics and operators of the pilot program made me propose to the Management to endow and reward with tool bonuses to these people. It was not possible because of the implications with the other operators. The idea remained pending.

Consolidation. …

The work includes:

- A continuous training and recycling for operators of the PM 2. A continuous training and recycling for mechanics of the PM and Repair: lines, dams, lithography, mechanical and electrical workshop.

- Adjustment of the frequencies of checks and points related to the “check lists”.

- A continuous administration of the work orders used in each intervention: labor, materials

- Prepare the annual budget according to the commercial program

- Monthly meeting with C. Quality to study the statistical control of the final quality defects as well as claims.

- An annual audit of productivity and quality condition carried out by the Technical D. (This was not done)

Finally, in March 1981, the recent Operations Directorate created in Madrid, whose director was Mr. Ascasibar, proposed to me to develop the following technical tasks for this office: follow up new investments, implementation of the MP and R. as well as the annual maintenance budget .

A new change of ownership in the Company resulted in the elimination of this office. As a result of it I became available.

In 1983 I was entrusted with a new task linked to the Agoncillo Factory (Logroño) equipped with a line for “two pieces” packaging format 209 / 211×412 -12oz. in tinplate But this is another story, very interesting where a complete MP and R. is vital.

0 Comments