Con un fin didáctico, para aquellos que no tengan fácil conocer en directo la fabricación de envases metálicos, se ofrece en este trabajo una serie de dibujos que describen las secuencias de fabricación de los diferentes tipos: botes 3 piezas, embutidos, embutidos-reembutidos (DRD) y embutidos estirados y planchados (DWI). A partir de los mismos será sencillo al entendido explicar a terceros el proceso.

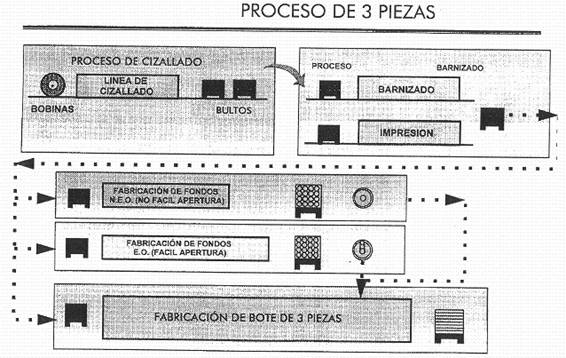

1º.- SECUENCIA DE FABRICACIÓN DE BOTES 3 PIEZAS

Se fabrica por separado los fondos, y posteriormente los cuerpos, a los que se le añade los fondos en la operación de cierre. La secuencia es como sigue:

2º.- ESQUEMA GENERAL DEL PROCESO DE FABRICACIÓN DE ENVASES 3 PIEZAS

En la fabricación por parte del metalgrafico hay cuatro etapas:

-Corte de bobinas

– Preparación de las hojas (Barnizado y litografiado)

– Fabricación de fondos y tapas

– Fabricación del bote propiamente dicho

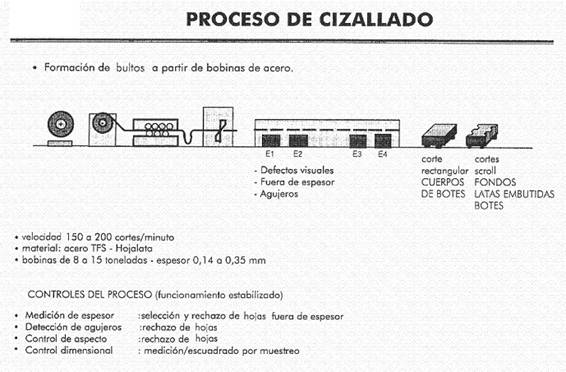

3º.- PROCESO DE CIZALLADO (CORTE DE BOBINAS)

Se realiza sobre una línea automática de corte de bobinas.

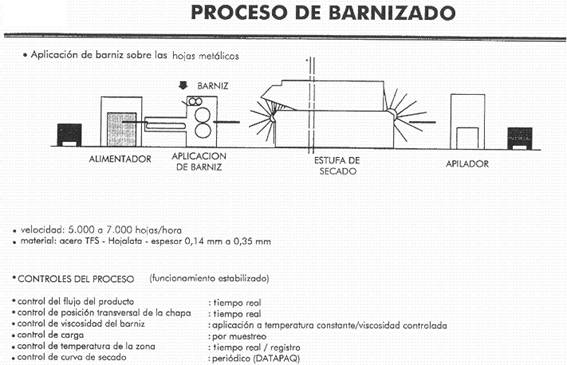

4º.- PROCESO DE BARNIZADO

El barniz se aplica sobre una maquina barnizadora de rodillos y se estufa en un horno continuo horizontal.

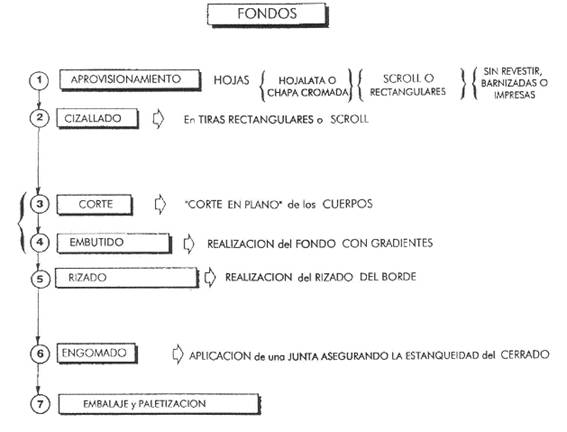

5º.- SECUENCIAS DE FABRICACIÓN DE LOS FONDOS

La fabricación de los fondos se lleva a cabo a través de las siguientes etapas:

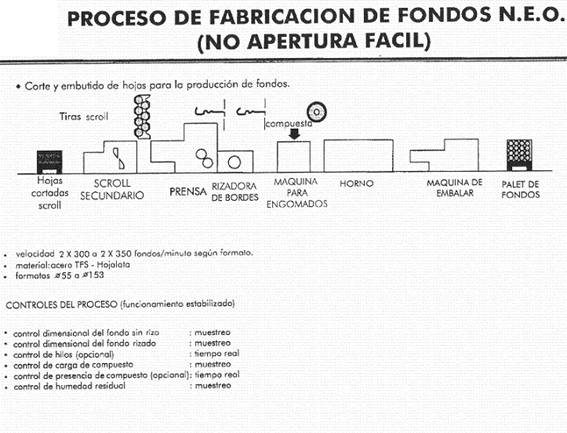

6.- PROCESO DE FABRICACIÓN DE LOS FONDOS CLASICOS

Los fondos tradicionales (no fácil apertura) requieren para su fabricación una instalación que esquemáticamente está formada por:

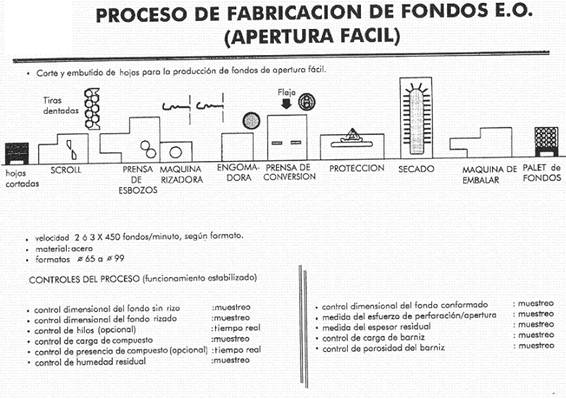

7º.- PROCESO DE FABRICACIÓN DE LAS TAPAS DE FACIL APERTURA

Presentan una primera parte igual a un fondo clásico, seguida de fase especial que lo transforma en fácil apertura. Su proceso queda reflejado en el siguiente dibujo:

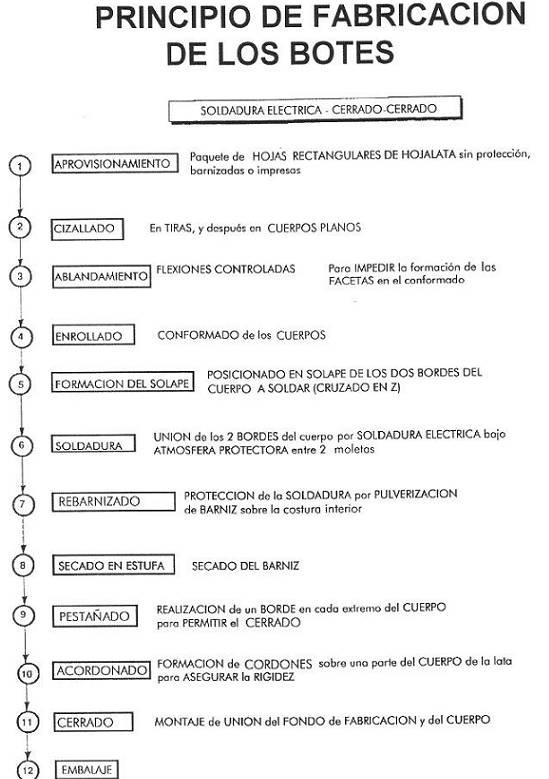

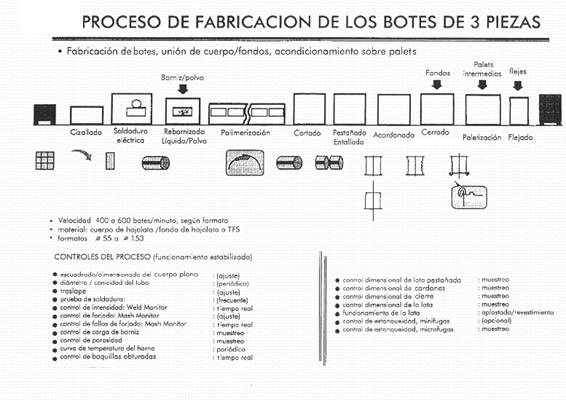

8º.- SECUENCIAS DE FABRICACIÓN DE LOS BOTES 3 PIEZAS

Se puede fraccionar en una serie de etapas, todas ellas enlazadas en la línea de fabricación, según la secuencia siguiente:

9º.- PROCESO DE FABRICACIÓN DE LOS BOTES TIPO 3 PIEZAS

Línea formada por una decena de maquinas unidas entre sí.

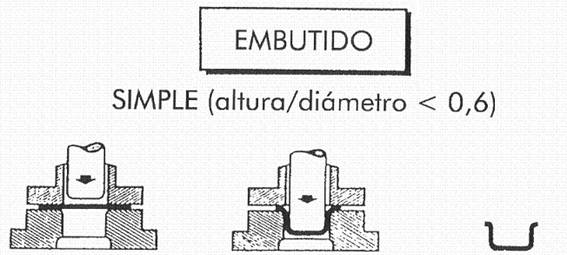

10º.- SECUENCIAS DE FABRICACIÓN DE LOS BOTES EMBUTIDOS

La fabricación de los botes embutidos difiere radicalmente de los anteriores. Está basada en el uso de prensas.

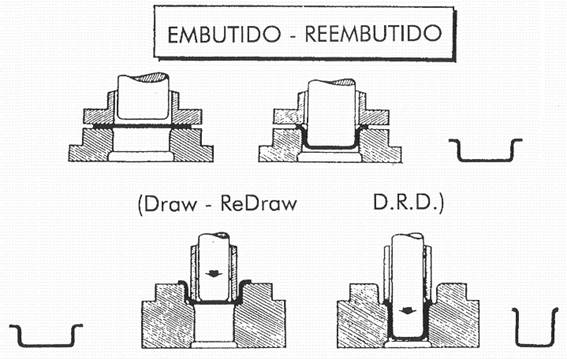

11º.- SECUENCIAS DE FABRICACIÓN DE LOS BOTES EMBUTIDOS –REEMBUTIDOS D. R. D.

Desarrollada para obtener envases embutidos altos, se consigue a base de varias embuticiones sucesivas.

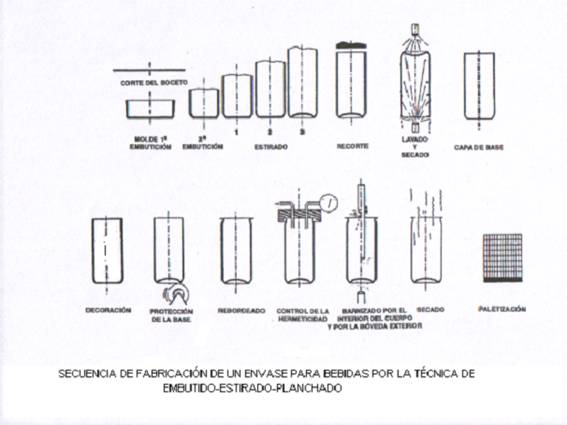

12º.- SECUENCIAS DE FABRICACIÓN DE LOS BOTES EMBUTIDOS ESTIRADOS Y PLANCHADOS D. W. I

Técnica empleada para contener productos (bebidas) siempre bajo presión interna. Emplea paredes de muy bajo espesor.

0 Comments