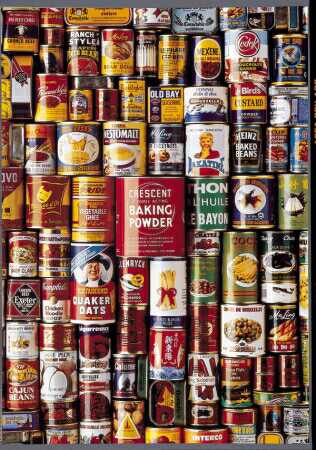

¿Los materiales para envases basados en acero pertenecen al pasado o al futuro?

Al tratar esta Web con frecuencia, los problemas mas comunes que se presentan en el uso de las latas, puede dar lugar a pensar que son ya medios inadecuados. Al contrario, habiendo sido aconsejados sobre sus límites y posibles incidentes es mucho más fácil utilizarlos dentro de un margen suficiente de seguridad y aprovechar enteramente sus ventajas. Dedicamos los siguientes comentarios a las cualidades principales del envasado basado en acero. Los problemas presentados por la corrosión, que ocurren en un número muy limitado de casos, son una minoría en comparación con los aspectos positivos de los envases de hojalata.

En el pasado, la producción, transformación y uso de la hojalata fueron tema de numerosas investigaciones, las cuales han continuado movilizando en la actualidad a laboratorios importantes que pertenecen a tres enlaces principales de la cadena, en concreto: los fabricantes del material, los fabricantes de los envases y los usuarios. Actualmente se utilizan los equipamientos de laboratorio más sofisticados para mejorar las características y el rendimiento del material. La producción en masa de los envases de metal a muy alta velocidad ha sido posible sobre todo por la ingeniería industrial.

En las últimas décadas del pasado siglo, gracias a estos esfuerzos de investigación y desarrollo, aparecieron una serie de nuevas técnicas de fabricación como fueron: los envases DWI (embutidos, estirados y planchados), DRD (embutidos y reembutidos), sin omitir los envases soldados eléctricamente, que reemplazaron los envases de costura lateral con cierre tradicional y soldados con una aleación de estaño/plomo. También los sistemas de Fácil Apertura, que ahora se utilizan de forma generalizada para los envases normales. Está aceptado como un hecho establecido, que gracias al diseño y desarrollo de revestimientos específicos orgánicos (barnices), se garantiza la inercia química del envase.

Si la producción de los envases de metal ahora ha llegado una precisión y regularidad tan alta, que está al límite de la perfección, es debido principalmente al progreso en la fabricación del acero, incluyendo la laminación en frío hasta el espesor final (hojalata doble reducida), los tratamientos térmicos y superficiales, etc. Así hemos entrado en una generación de envases ultraligeros, de paredes tan delgadas, que hacen solo unas décadas era impensable.

Este clima de investigación e innovación promueve asociaciones y asistencia mutua entre los fabricantes de materiales y los fabricantes de envases por un lado, y entre los fabricantes de envases y los llenadores por otro.

¿Cuáles son las ventajas técnicas de los envases basados en el acero?

Mencionaremos las más importantes sin organizarlas en orden de importancia, debido a que todas interactúan con las 5 funciones principales que cualquier envase de alimentos deberá principalmente satisfacer:

– adecuado contenido y conservación

– que constituya una unidad de alimento para el consumo

– que se puedan producir y transportar fácilmente

– que sea de uso práctico

– que contengan un mensaje

Comparado con estas funciones, el envase de metal tiene las siguientes ventajas:

– consistencia y resistencia a golpes

– aislamiento integral a gases y microorganismos

– impermeabilidad absoluta

– no se deteriora por la acción del calor o frío

– una conductividad buena de calor y frío

– material magnético, por lo tanto fácil de manejar y separar para fines de reciclado

– inercia química perfectamente controlada debido al uso de los revestimientos orgánicos

– una base excelente para los tintas y lacas decorativas

– un reciclado fácil, es decir material ecológico

Brevemente comentaremos cada uno de estos:

- a) El envase de metal es sólido, con una buena resistencia a los golpes

Es irrompible. El vidrio, su principal competidor en algunas áreas del envasado de alimentos está especulando sobre “llegar a ser tan resistente como el acero”. Cuando se compara con otros envases, los metálicos no son frágiles durante el manejo y transporte y pueden hacer frente al mal trato más fácilmente. Los límites elásticos altos son inherentes al acero.

- b) El envase de metal es impermeable a la luz, gases y microorganismos

Esto es una ventaja importante. Es necesario conservar la estabilidad bioquímica y microbiológica del alimento. La influencia perjudicial de la luz y de la radiación UV es una realidad, dando lugar a algunas modificaciones particularmente de color y de sabor. La pared metálica del envase también constituye una barrera impermeable a todos los gases. El oxígeno del aire, un agente de oxidación por excelencia, no puede llegar al alimento. Dicha impermeabilidad a los gases también es efectiva en el sentido contrario. Los gases que se forman dentro del envase, debido a la corrosión o alteración microbiológica (esterilización insuficiente o recontaminación) son mantenidos dentro del mismo, llegando a deformarlo, poniendo de manifiesto así anormalidades que son incompatibles con la naturaleza higiénica y sanitaria del producto.

El envase de metal, que conserva la comida procesada térmicamente, es una seguridad eficaz contra los microbios durante meses, e incluso años. En particular, protege la conserva contra los microbios patógenos del entorno. Ofrece una seguridad de primer orden a la posibilidad de casi duplicarse los microbios cada veinte minutos a ciertas temperaturas.

- c) La impermeabilidad de envases de 3 piezas está asegurada por una costura lateral soldada eléctricamente y por el doble cierre de los extremos. Los envases embutidos, se convierten en impermeables solamente por medio del doble cierre del extremo superior. Al contrario que los recipientes de cristal, que tienen que acudir a otro material (en este caso al metal) para poder lograr la impermeabilidad, el envase de metal constituye un sistema homogéneo que aguantará diferencias de presión con el exterior de varios bares. En un envase lleno, que se mantenga sin presencia de corrosión interna, o de fenómenos de alteración microbiológicos, el vacío interno es mantenido siempre. De la misma manera, no existe una pérdida de gas en las bebidas carbonatadas, durante su almacenamiento bajo cualquier condición climática externa.

- d) El envase de metal no se ve afectado ni por el calor ni por el frío.

Sus propiedades físicas, mecánicas y químicas aguantaran todas las desviaciones de temperatura observadas en su entorno, incluso ocasionalmente elevadas.

- e) El envase de metal permite la transferencia de calor y de frío

La evolución en la tecnología de los envases es tal que permite cada vez más los ciclos de procesos térmicos “cortos y altos” (tiempo corto – temperatura alta). El acero es el más adecuado para esta evolución, la cual ha mejorado la conservación de las propiedades nutritivas y organolépticas de los alimentos envasados.

- f) Es muy apreciada la propiedad magnética del acero durante las operaciones de manipulación. Entre todos los materiales de envasado, es el único que se beneficia de esta propiedad. Hace que su separación y su selección en la basura anterior a la incineración u otro sistema de eliminación sea muy fácil.

9) El tratamiento superficial de la hojalata y del acero libre de estaño (TFS), permite la aplicación de las mejores resinas orgánicas en capas muy finas, con una alta adherencia, asegurando la inercia química del metal. Gracias a estas capas orgánicas, el envase de metal, aunque no puede conseguir la misma inercia que el vidrio, ha podido ser aplicado a la conserva de un número impresionante de alimentos y productos industriales.

- h) En el campo de la decoración es difícil mejorar la presentación de la hojalata, donde el estaño, por su fuerza reflectora, hace resaltar el brillo de los tintas. La hojalata es la elección idónea para la fabricación de bandejas y cajas lujosamente decoradas. Cuadros famosos han sido reproducidos en este material con gran realismo y calidad.

En este campo, es digno destacar que puede ser impresa en plano la litografía de envases embutidos. Para ello se recurre a un deformado previo (procedimiento de anamorfosis) para que la decoración esté proporcionada después de la operación de formación. Este logro es debido a la destreza combinada del metalúrgico – que ha logrado ser experto en los alargamientos orientados con referencia a la dirección del laminado – a la tinta y al diseñador y fabricante de laca, al especialista fotomecánico, al impresor y finalmente al fabricante de los envases.

- i) Finalmente, el acero del envase metálico es un material que no daña el ambiente.

Hoy en día, todos los materiales usados en la industria del embalaje, están obligados a tener en cuenta un factor ambiental. De todos los materiales metálicos, el acero muestra la tendencia más natural para volver a su estado original, es decir, a sufrir un proceso de oxidación transformándose en óxido de hierro. Es, a su manera, biodegradable con el tiempo. Su magnetismo permite el reciclado industrial por medio del circuito tradicional de selección de basura doméstica, no como otros materiales (aluminio, plásticos) que necesitan procedimientos más complejos.

El acero utilizado para materiales de envasado es de grado extra suave sin componentes particulares. Sus distintas características, como su elasticidad, el límite elástico, carga de rotura, etc., están esencialmente ligadas con los tratamientos térmicos aplicados. Los envases, una vez vacíos pueden volver a la siderurgia en forma de chatarra y se convertirán de nuevo en acero. De esta manera los envases contribuyen a un ahorro de energía

Los miles de millones de envases de acero actualmente fabricados cada año en el mundo, son una evidencia suficiente de que el material satisface las necesidades de los usuarios. Los contenedores de metal con una base de acero tienen la ventaja de una buena relación calidad/precio.

La hojalata todavía no ha agotado las posibilidades de innovación. Los ingenieros que trabajan en las acerías y en las siderurgias siguen proporcionando al fabricante de envases grados de calidad cada vez mas específicos de acuerdo con la forma de trabajar del metal, (expansión, estiramiento etc.). Se puede afirmar que la hojalata es un producto que puede ser seleccionado en función de su utilización

En el campo del envasado, siempre cambiante, la exclusividad está fuera de lugar y es positivo pensar que en el futuro se usará un material cada vez más complejo. En estas futuras asociaciones, el uso del acero no correrá un peligro excesivo.

0 Comments