Some canning factories, to determine the tightness of the containers especially in the reception controls, use water testers but some of the facilities do not have adequate systems.

For all these factories and for those that having other systems have the need to verify hermeticities at any point in their industry, the packaging tester was designed, described below, which can be done with the help of the hands of an operator, the operations necessary to develop its function, and which are: drill, threaded, air injection and test pressure measurement.

The tester consists of a manual neumatic pump, used to inflate bicycle wheels, at the end of which fits a bushing, which serves as a union to a body, on which a manometer is mounted to check the air pressure inside the container.

Said body is provided in its inlet with a check valve to prevent the backward movement of the air, and at its other end of a device that allows the drilling of the lid of the container and its subsequent threading, until ensuring the hermeticity of the container thanks to a elastic joint.

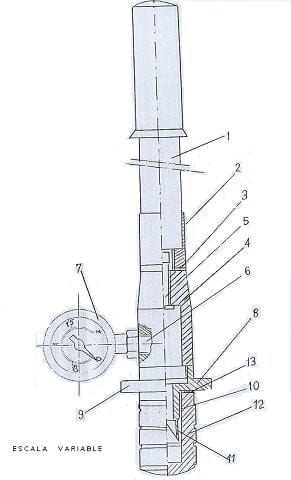

For a better understanding of the system in question, a detailed description is made below with reference to the attached design, in which a semi-detailed view of the tester has been represented.

Manual waterproofing tester

The tester consists essentially of a bicycle-type pump 1 which is provided at its end with a bushing 2. To said bushing 2 a body 4 is fixed, interposing a washer 3 of elastic material to ensure sealing. The body 4 internally has a check valve 5 to maintain the pressure of the air injected into the container. An orifice 6 through which the inside of said body can be put in communication with a manometer 7 to control the pressure to which the container to try. The free end of said body 4 is hermetically coupled to a drill-threading part 8 which is provided with a peripheral flange 9 and a thread. 10 of square profile whose height grows progressively from zero. This piece ends with two triangles 11 at its end, in form V, sufficiently sharp to allow its penetration into the lid of the container. At the end of the tester and in order to protect the edges of the “triangles” there is a plug 12, between the end of said plug and the peripheral flange 9, of the drill-threading part 8 a washer 13 of elastic material , whose mission is to ensure the tightness of the tester and the container whose tightness is to be verified.

The functioning of the tester is as follows:

The tester is grasped with one of the hands resting on the body 4 and, resting the thumb and forefinger on the flange 9 of the drill-threading piece 8, it is pressed with one of the triangles “in a vee 11 on the center of the lid of the container whose tightness we want to verify, the operation is repeated with the other “triangle” 11 and it is given a 90º turn in order to finish detaching the drilled tin disc.

The container is threaded with the thread 10 of the drill-threading part 8, for this there is no more than to turn the tester clockwise, relative to the container, until the cover of the latter abuts the rubber ring 13. At this time, the ring 13 will ensure the tightness with the convenient fix. This tight will be made by hand and without the need of any special tool.

With pump 1, pressurized air is injected until reaching the pressure at which the container is to be tested; obtained and controlled by means of the manometer 7, the container is introduced into a container with water.

In all systems for determining leaks by means of air, an airtight container shall be considered if, after allowing all the air occluded in the closure to escape, no air bubble appears in 10 seconds. The normal test pressure is 1 bar.

Another application of this manual tester is to be able to determine from what pressure the lid opposite to the one making the hole, it is permanently deformed, – it does not recover – even if the internal pressure stops working.

0 Comments